The most critical precautions for using a muffle furnace fall into three categories: preventing personal injury, protecting the equipment from damage, and ensuring the integrity of your experiment. These are not just rules to follow but principles to understand, as failure to do so can result in severe burns, equipment failure, fire, or ruined samples.

A muffle furnace is a precision instrument, not just a simple oven. Its safe and effective operation depends on a systematic approach that begins before the power is turned on and ends long after it has cooled down.

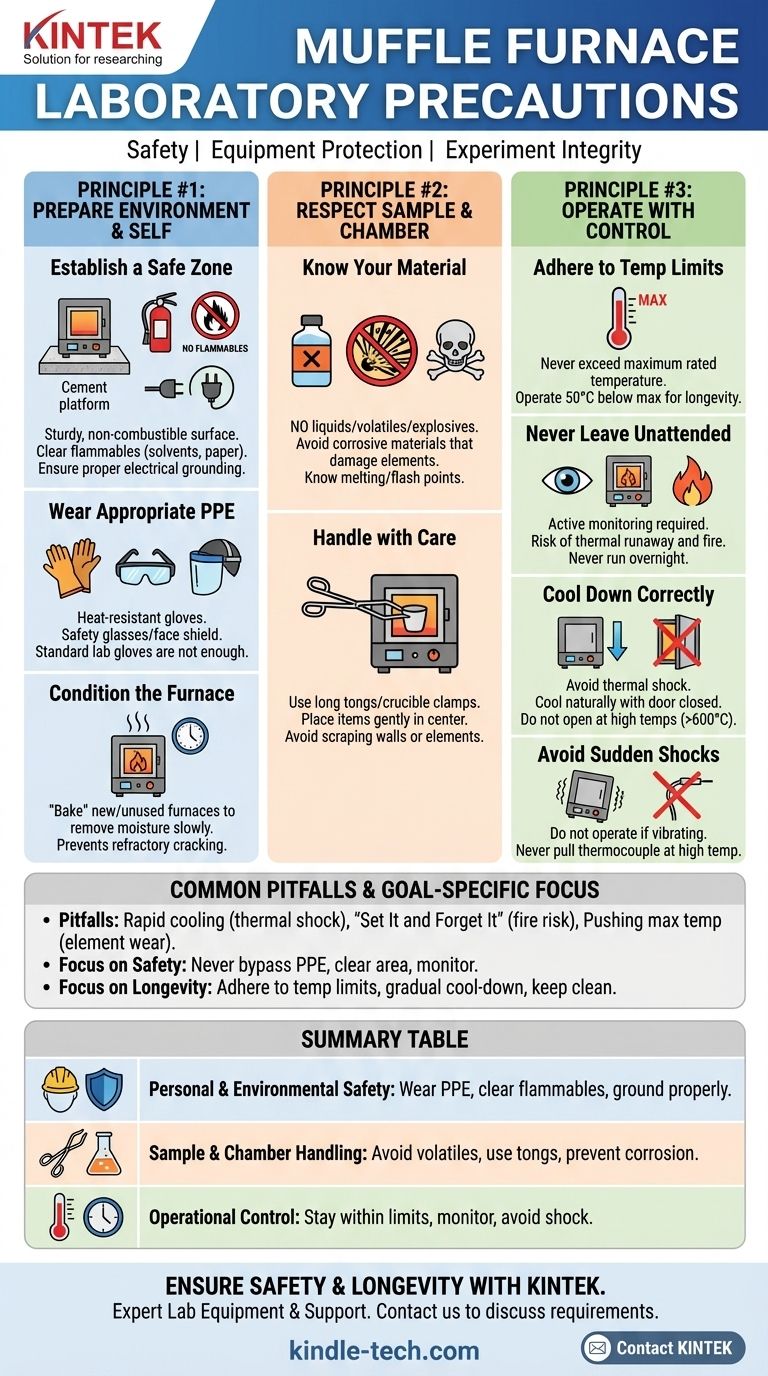

Principle #1: Prepare Your Environment and Yourself

Before you even consider heating a sample, you must ensure the foundation for safety is in place. This involves securing the physical space and properly equipping the operator.

Establish a Safe Zone

A muffle furnace generates extreme external heat and requires significant electrical power. It must be placed on a sturdy, level, and non-combustible surface, such as a dedicated cement platform.

The surrounding area must be completely clear of flammable and combustible materials. This includes solvents, paper, and cleaning rags.

Ensure the furnace is connected to a properly rated electrical circuit with the correct plugs, sockets, and fuses. Proper grounding is non-negotiable to prevent electrical shock.

Wear Appropriate Personal Protective Equipment (PPE)

The risks of severe thermal burns are high. Always wear heat-resistant gloves and safety glasses or a face shield when handling items that are being placed into or removed from the furnace.

The type of glove must be appropriate for the working temperature. Standard lab gloves offer no protection from the radiant heat of an open furnace door.

Condition the Furnace Before Use

If the furnace is new or has been unused for an extended period, it will have absorbed moisture into its refractory lining. This moisture must be driven out slowly to prevent damage.

This is done by "baking" the furnace: heating it at a low temperature for several hours before gradually increasing it. Failure to do this can cause steam to rapidly expand within the refractory material, leading to cracks.

Principle #2: Respect the Sample and the Chamber

What you put inside the furnace, and how you put it there, directly impacts safety and the equipment's lifespan.

Know Your Material

Never place liquids, volatile substances, or explosive materials into the furnace chamber. Rapid heating can cause uncontrolled vaporization or ignition.

Samples containing fats, oils, or certain plastics can release corrosive gases as they heat. These gases will attack and destroy the surface of the heating elements, dramatically shortening their lifespan. If you must heat such materials, use a sealed container with proper ventilation.

Know the melting and flash points of everything you place inside the chamber to prevent unexpected reactions.

Handle with Care

Always use long tongs or crucible clamps to load and unload samples. This keeps your hands away from the intense heat.

Place items gently into the center of the chamber. Dropping or scraping items against the chamber walls or heating elements can cause immediate and expensive damage.

Principle #3: Operate with Deliberate Control

A muffle furnace is not a "set it and forget it" device. It requires active monitoring and a disciplined operational sequence.

Adhere to Temperature Limits

Never operate the furnace above its maximum rated temperature. This will burn out the heating elements and can cause catastrophic failure.

For routine use and to maximize the lifespan of the heating elements, it is best practice to operate at least 50°C below the maximum temperature.

Never Leave It Unattended

A furnace in operation must be monitored. Control systems can fail, and thermocouples can malfunction, leading to a thermal runaway situation that creates a significant fire hazard. Never run a furnace unattended overnight.

If you observe any abnormalities, such as unusual noises, smoke, or a temperature display that does not match the setpoint, shut down the power immediately and have the unit inspected.

Cool Down Correctly

Never open the furnace door at high temperatures (e.g., above 600°C) to cool it down faster. The sudden inrush of cool air creates thermal shock, which can crack the furnace's refractory lining and potentially shatter your sample.

Always turn off the power and allow the furnace to cool naturally with the door closed.

Avoid Sudden Shocks

Do not operate the furnace if it is vibrating. More importantly, never pull the thermocouple out of its port while the furnace is at a high temperature. The rapid temperature change can cause the protective ceramic jacket to shatter.

Understanding the Common Pitfalls

New users are often tempted to take shortcuts that compromise safety and equipment longevity for the sake of speed.

The Temptation of Rapid Cooling

The desire to access a sample quickly is strong, but opening the door on a hot furnace is one of the most common ways to cause permanent damage. The time saved is not worth the cost of replacing the furnace lining.

The "Set It and Forget It" Fallacy

Treating the furnace like a household oven is a critical mistake. Its power and temperature capabilities demand respect. A simple controller failure can turn an unattended furnace into an uncontrolled fire source.

Pushing to Maximum Temperature

While the furnace is rated to a maximum temperature, operating it constantly at this limit is like running a car's engine at its redline. It drastically accelerates wear on the most critical components—the heating elements.

Applying These Precautions to Your Goal

Your specific priorities will determine which precautions demand the most focus.

- If your primary focus is operator safety: Never bypass PPE, always ensure the area is clear of flammables, and never operate the furnace unattended.

- If your primary focus is equipment longevity: Adhere strictly to temperature limits, always perform a gradual cool-down, and keep the chamber clean from corrosive residues.

- If your primary focus is experimental accuracy: Always condition a new or long-unused furnace to drive off moisture and ensure your samples are free from contaminants that could off-gas and interfere with your process.

Mastering the use of a muffle furnace is achieved through discipline and a deep respect for its power.

Summary Table:

| Precaution Category | Key Actions |

|---|---|

| Personal & Environmental Safety | Wear heat-resistant PPE, clear flammable materials, ensure proper grounding. |

| Sample & Chamber Handling | Avoid volatile materials, use correct tongs, prevent corrosive gas release. |

| Operational Control | Never exceed temperature limits, avoid unattended operation, prevent thermal shock during cool-down. |

Ensure the safety and longevity of your lab equipment. Properly using a muffle furnace is critical for protecting your personnel and your research integrity. KINTEK specializes in high-quality lab equipment and consumables, serving all your laboratory needs. Our experts can help you select the right furnace and understand best practices for safe operation.

Contact KINTEK today to discuss your specific requirements and ensure your lab operates safely and efficiently.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Does a muffle furnace need to be vented? Essential Safety and Performance Guide

- How do you calibrate a muffle furnace? Achieve Precise Temperature Control for Your Lab

- What are the parts of a muffle furnace? Uncover the Core Components for Precision Heating

- What is a muffle furnace used for? Achieve Pure, High-Temperature Processing

- How do you maintain a muffle furnace? Ensure Safety and Maximize Equipment Lifespan