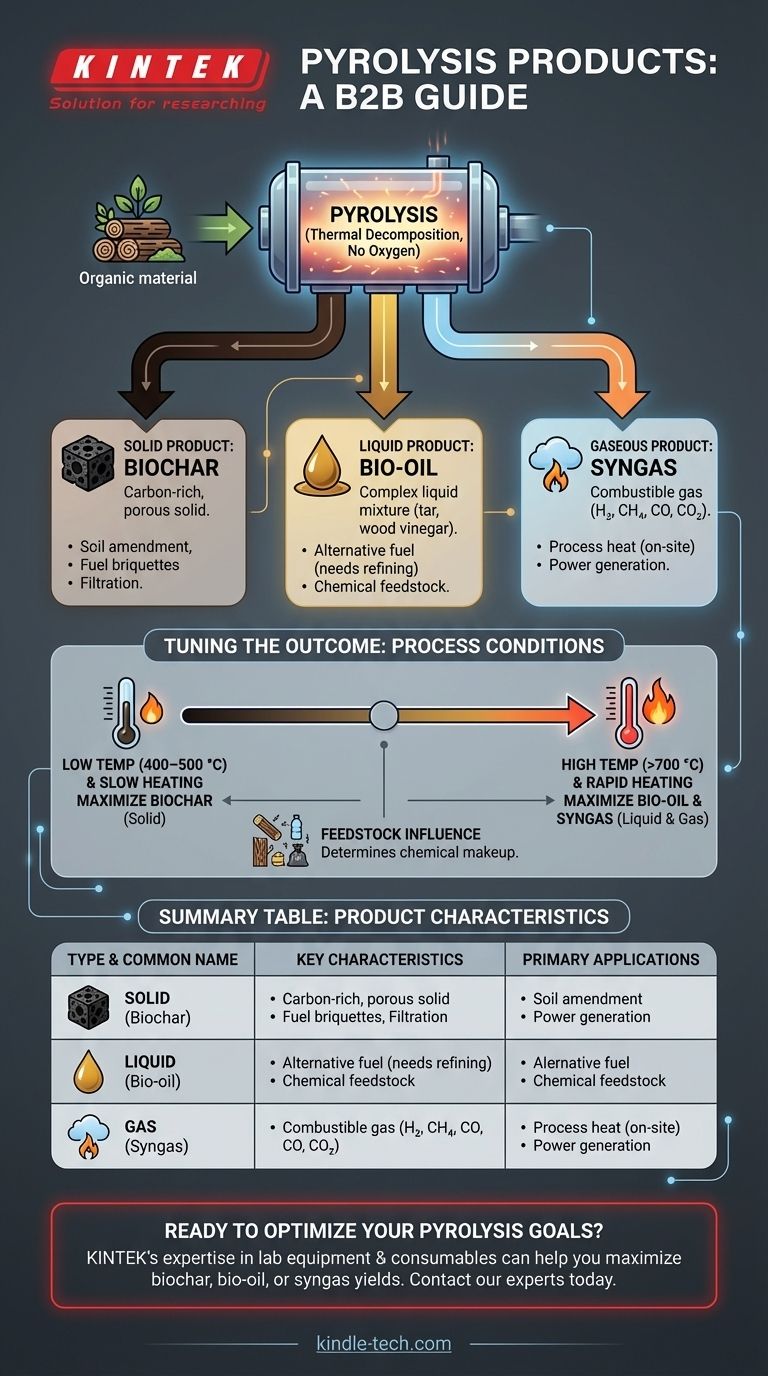

In short, pyrolysis yields three distinct categories of products. The process thermally decomposes organic material in the absence of oxygen, breaking it down into a solid, a liquid, and a gas. The solid is a carbon-rich substance called biochar or coke, the liquid is a complex mixture known as bio-oil or pyrolysis oil, and the gas is a non-condensable mixture often called syngas.

Pyrolysis is not a fixed recipe with a single outcome. It is a highly tunable process where the input material and operating conditions—especially temperature—are deliberately adjusted to control which of the three product types (solid, liquid, or gas) is maximized.

The Three Core Product Categories

Pyrolysis fundamentally deconstructs complex organic matter into simpler, more valuable components. Each of the three product streams—solid, liquid, and gas—has a unique composition and set of applications.

The Solid Product: Biochar

The most visible product is the solid carbon residue left behind, commonly known as biochar (from biomass) or coke.

This material is highly porous and rich in carbon. Its primary uses include agricultural soil amendment, creating energy briquettes, and acting as a sorbent for filtration.

The Liquid Product: Bio-oil

As the hot pyrolysis gases are cooled, a complex liquid mixture condenses out. This is known as bio-oil, pyrolysis oil, or sometimes tar and wood vinegar.

This liquid can serve as an alternative fuel, though it often requires refining before use. It also contains a wide array of valuable chemicals that can be extracted for other applications.

The Gaseous Product: Syngas

The remaining non-condensable gases form a mixture called syngas or pyrolysis gas.

This gas is a combination of hydrogen (H₂), methane (CH₄), carbon monoxide (CO), and carbon dioxide (CO₂). It is combustible and very often used on-site to provide the heat needed to power the pyrolysis process itself, creating a self-sustaining energy loop.

How Process Conditions Dictate the Outcome

You cannot understand pyrolysis products without understanding that the process itself is the primary variable. The specific yield of char, oil, and gas is a direct result of the operational choices made.

The Critical Role of Temperature

Temperature is the most significant lever for controlling the output.

Generally, lower to moderate temperatures (around 400–500 °C) with slower heating rates will maximize the yield of solid biochar.

Conversely, higher temperatures (above 700 °C) and rapid heating favor thermal cracking, which maximizes the production of liquid (bio-oil) and gaseous (syngas) fuels.

The Influence of Feedstock

The starting material, or feedstock, determines the precise chemical makeup of the final products.

Pyrolyzing wood will produce different ratios of chemicals in its bio-oil compared to pyrolyzing agricultural waste or plastics. The choice of feedstock is the first step in targeting a specific desired outcome.

Understanding the Trade-offs

Optimizing for one product inevitably affects the others. This balance is central to designing and operating a pyrolysis system for a specific goal.

Yield of One vs. Yield of Another

A process tuned for maximum bio-oil production will, by definition, produce less biochar. The goal is not to get "all three" in high quantities, but to efficiently convert the feedstock into the most desired product stream.

Energy Self-Sufficiency vs. Gas Sales

Using the produced syngas to fuel the pyrolysis reactor is a common and efficient practice. However, this means the gas is consumed internally and is not available as a final product to be sold or used for external power generation.

Raw vs. Refined Products

The liquid bio-oil is not a direct substitute for diesel or gasoline. It is typically acidic and unstable, requiring further processing and refining to be used as a high-grade fuel, which adds complexity and cost to the overall process.

Making the Right Choice for Your Goal

To apply pyrolysis effectively, you must align the process parameters with your primary objective.

- If your primary focus is carbon sequestration or soil improvement: Use slower pyrolysis at moderate temperatures (400–500 °C) to maximize the yield of stable, solid biochar.

- If your primary focus is producing liquid fuels or chemical feedstocks: Use fast pyrolysis at higher temperatures (above 700 °C) to convert the maximum amount of biomass into bio-oil.

- If your primary focus is generating a combustible gas for power: Use very high-temperature gasification (a related process) to maximize the conversion of the material into syngas.

Ultimately, viewing pyrolysis as a flexible conversion platform, rather than a rigid process, is the key to unlocking its potential.

Summary Table:

| Product Type | Common Name | Key Characteristics | Primary Applications |

|---|---|---|---|

| Solid | Biochar / Coke | Carbon-rich, porous solid | Soil amendment, fuel briquettes, filtration |

| Liquid | Bio-oil / Pyrolysis Oil | Complex liquid mixture | Alternative fuel, chemical feedstock |

| Gas | Syngas | Combustible gas (H₂, CH₄, CO) | Process heat, power generation |

Ready to select the right pyrolysis process for your specific goals? Whether your project requires maximizing biochar for carbon sequestration, bio-oil for fuel production, or syngas for energy, KINTEK's expertise in lab equipment and consumables can help you optimize your results. Contact our experts today to discuss your laboratory's pyrolysis needs and discover the right solutions for your research.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products