The fundamental safety precautions for argon welding revolve around protecting yourself from four primary hazards: the intense ultraviolet (UV) radiation from the arc, the inhalation of hazardous fumes and gases, the risk of severe electric shock, and the asphyxiation potential of argon gas itself. Proper Personal Protective Equipment (PPE), adequate ventilation, and a well-prepared workspace are not optional—they are essential requirements for any welding operation.

The core principle of welding safety is not just about wearing a helmet. It's about creating a controlled environment where you actively manage the multiple, simultaneous risks of radiation, fumes, electricity, and gas displacement before you ever strike an arc.

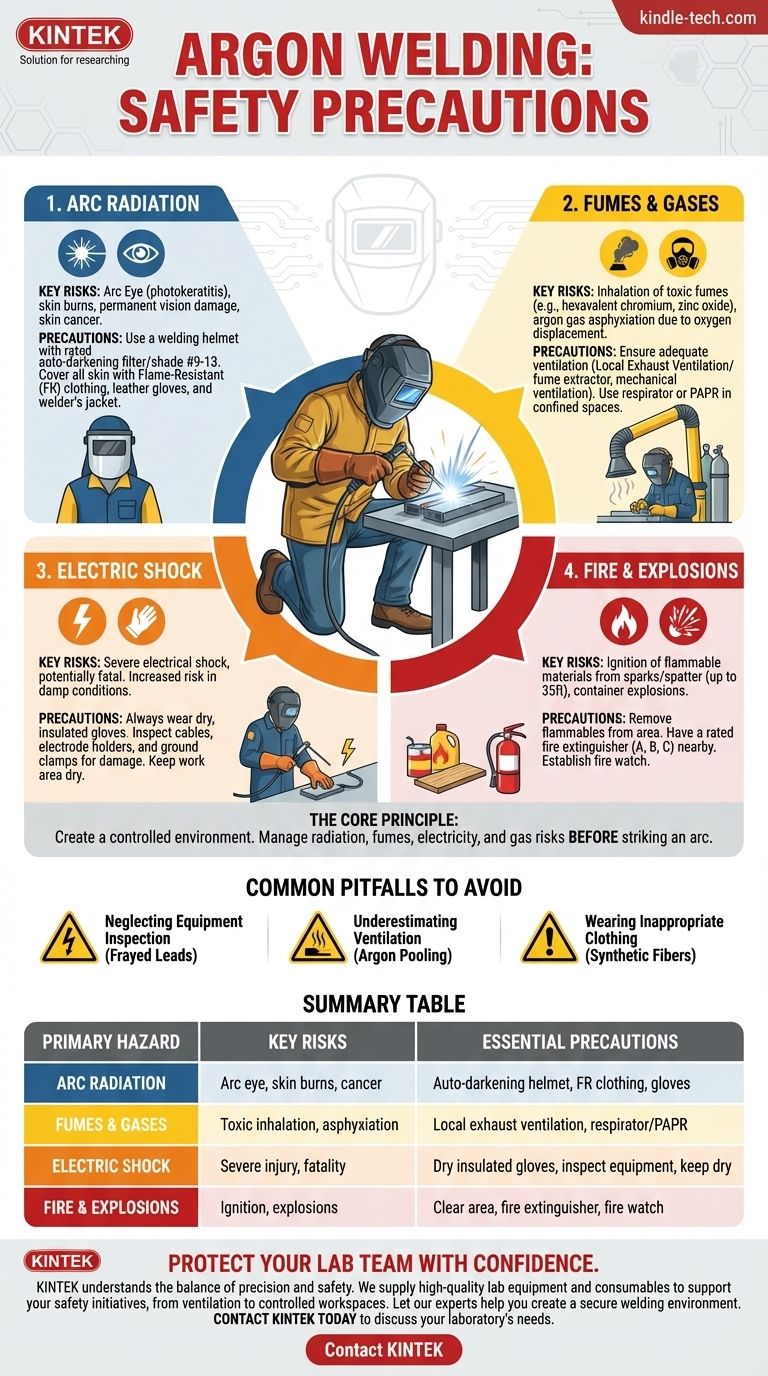

The Four Pillars of Welding Safety

Most accidents in welding—whether using TIG (GTAW) or MIG (GMAW) processes with argon—can be traced back to a failure in one of four key areas. Understanding each hazard is the first step to mitigating it.

Hazard 1: Arc Radiation

The welding arc produces extremely intense ultraviolet (UV) and infrared (IR) radiation. This is a significant danger to both your eyes and skin.

Unprotected exposure, even for a few seconds, can cause a painful condition called photokeratitis, more commonly known as "arc eye" or "welder's flash." It feels like having sand in your eyes and can cause temporary vision loss.

Long-term exposure to arc radiation is a known cause of permanent eye damage and skin cancer. Your skin can receive a severe sunburn from just minutes of exposure.

To prevent this, you must use a welding helmet with a properly rated auto-darkening filter or a fixed-shade lens (typically shade #9-13). You must also cover all exposed skin with flame-resistant (FR) clothing, a welder's jacket, and leather gloves.

Hazard 2: Fumes and Gases

The welding process vaporizes the base metal, filler metal, and any coatings present, creating a plume of toxic fumes and gases.

This isn't just smoke; it's a complex mixture of metallic oxides and gases. Welding on stainless steel, for example, can release hexavalent chromium, a known carcinogen. Welding on galvanized steel releases zinc oxide fumes, which can cause "metal fume fever."

The shielding gas, argon, is non-toxic, but it is an asphyxiant. It is heavier than air and can displace oxygen in your breathing zone.

The primary defense is ventilation. This can be local exhaust ventilation (LEV), which uses a fume extractor arm to capture fumes at the source, or general mechanical ventilation. In confined spaces or with hazardous materials, a respirator or a powered air-purifying respirator (PAPR) is required.

Hazard 3: Electric Shock

Arc welding uses a high-current, low-voltage open electrical circuit. This presents a constant and serious risk of electric shock, which can be fatal.

The danger comes from touching two metal objects that have voltage between them, such as the electrode and the workpiece simultaneously. The risk is significantly higher in damp or wet conditions.

Always wear dry, insulated gloves in good condition. Keep your work area dry, and inspect all cables, electrode holders, and ground clamps before each use to ensure they are not frayed or damaged.

Hazard 4: Fire and Explosions

The welding arc, sparks, and spatter can reach temperatures exceeding 10,000°F (5,500°C). These can easily ignite flammable materials in the surrounding area.

Sparks can travel surprisingly far—up to 35 feet. Any flammable materials, such as wood, paper, gasoline, or cleaning solvents, must be removed from the welding area.

Always know the location of the nearest fire extinguisher (rated for Class A, B, and C fires) and have a fire watch present for critical jobs. Never weld on or near closed containers, as heat can cause them to explode.

Common Pitfalls to Avoid

Even experienced professionals can become complacent. Trust is built on acknowledging and avoiding common mistakes.

Neglecting Equipment Inspection

A frayed welding lead or a faulty ground clamp is not a minor issue; it is a primary cause of electric shock. Make a pre-use inspection of all your equipment a mandatory, non-negotiable habit.

Underestimating Ventilation Needs

Do not assume a large, open shop is "well-ventilated." Fumes can concentrate in your breathing zone, and argon gas can pool in low-lying areas or pits. Always use mechanical ventilation or source extraction.

Wearing Inappropriate Clothing

Standard cotton or synthetic clothing (like polyester or nylon) is a fire hazard. It can melt to your skin or ignite from a single spark. Only wear designated flame-resistant clothing or heavy, natural-fiber materials like leather or wool.

Making the Right Choice for Your Goal

Your specific task should guide your safety priorities. Before you begin, assess your environment and materials to determine the most significant risk.

- If your primary focus is working in a confined space: Prioritize air monitoring and forced ventilation due to the severe asphyxiation risk from argon displacing oxygen.

- If your primary focus is welding stainless or coated metals: Your greatest risk is the inhalation of toxic fumes; a fume extractor or personal respirator is essential.

- If your primary focus is working outdoors or in a damp location: The risk of electric shock is magnified; ensure all equipment is perfectly insulated and you are standing on a dry, non-conductive surface.

- If your primary focus is fabrication in a busy workshop: Your first step is to clear all flammable materials and establish a safe perimeter to protect yourself and others from sparks and arc flash.

Ultimately, a safe weld is a professional weld; make safety your most essential tool.

Summary Table:

| Primary Hazard | Key Risks | Essential Precautions |

|---|---|---|

| Arc Radiation | Arc eye, skin burns, cancer | Auto-darkening helmet, flame-resistant (FR) clothing, gloves |

| Fumes & Gases | Toxic fume inhalation, oxygen displacement (asphyxiation) | Local exhaust ventilation (fume extractor), respirator/PAPR |

| Electric Shock | Severe injury, fatality | Dry insulated gloves, inspect cables/grounds, keep work area dry |

| Fire & Explosions | Ignition of flammable materials, container explosions | Clear area of flammables, have fire extinguisher, maintain fire watch |

Protect Your Lab Team with Confidence

Argon welding safety is non-negotiable for professional results and operator well-being. KINTEK understands the critical balance between precision work and stringent safety protocols in a laboratory setting.

We supply high-quality lab equipment and consumables designed to support your safety initiatives, from ensuring proper ventilation to maintaining a controlled workspace. Let our experts help you select the right tools to create a secure and efficient welding environment.

Contact KINTEK today to discuss your laboratory's specific needs. We are here to provide solutions that keep your team safe and your operations running smoothly.

Visual Guide

Related Products

- Anti-Cracking Press Mold for Lab Use

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Test Sieves and Sieving Machines

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Benchtop Laboratory Freeze Dryer for Lab Use

People Also Ask

- What roles do graphite molds play during vacuum hot pressing of Al-Sc alloys? Ensure Precision & Purity

- Why is hot press molding preferred over traditional solution casting? Expert Comparison for Polymer Electrolytes

- What are the advantages of using high-strength graphite molds in the hot press sintering of Ti6Al4V-based composites?

- What are the specific functions of graphite molds in the vacuum hot-press sintering process? Expert Insights for Ceramics

- What role does a high-purity graphite mold play during hot pressing? Optimize Boron Carbide Sintering at 1850°C