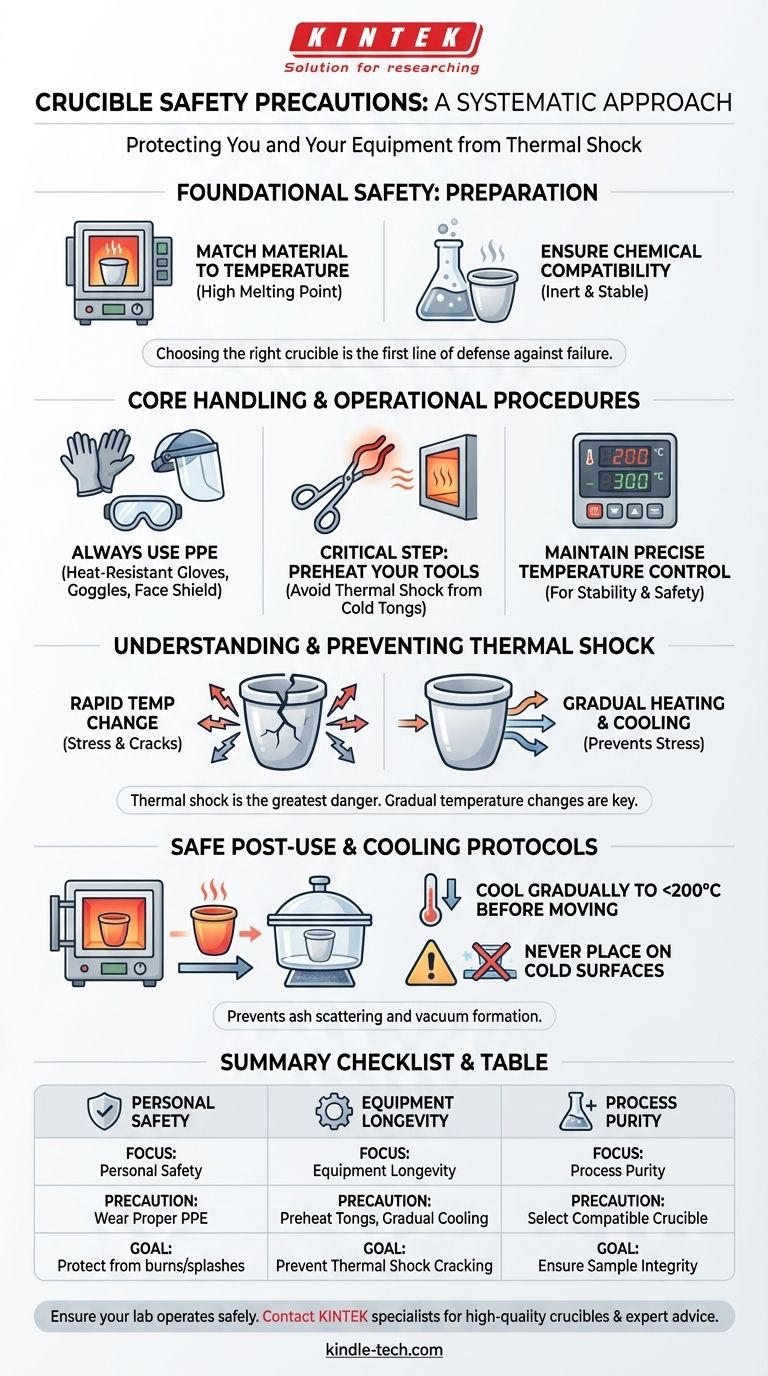

The essential safety precautions for a crucible involve a systematic approach that covers preparation, handling, and cooling. You must always wear appropriate personal protective equipment (PPE), preheat any tools like tongs before they touch a hot crucible, and follow a strict, gradual cooling protocol after use to prevent catastrophic failure from thermal shock.

The core principle of crucible safety is not just about protecting yourself from heat, but about protecting the crucible itself. Preventing thermal shock—the stress caused by rapid temperature change—is the key to avoiding cracks, spills, and potential accidents.

Foundational Safety: Selecting the Correct Crucible

Before you even approach a furnace, safety begins with choosing the right equipment for the job. Using an inappropriate crucible is a primary source of failure and risk.

Match Material to Temperature

A crucible must have an extremely high resistance to temperature. Its melting point must be significantly higher than the materials it is intended to contain to prevent a catastrophic failure during heating.

Ensure Chemical Compatibility

The crucible material must be chemically inert and stable relative to the substances being heated. A chemical reaction between the crucible and its contents can cause deterioration, contaminate your sample, and create unpredictable hazards.

Core Handling and Operational Procedures

Once the correct crucible is selected, a strict set of handling procedures must be followed to ensure a safe operation from start to finish.

Always Use Personal Protective Equipment (PPE)

This is the most direct line of defense. Always wear heat-resistant gloves, safety goggles, and a face shield, especially when handling molten materials or during the cleaning process after use.

The Critical Step: Preheating Your Tools

Never touch a hot crucible with cold tools. Crucible tongs must be preheated for a few moments in or near the furnace before being used to handle the crucible.

Introducing a cold object to the hot ceramic or graphite surface creates a point of intense thermal shock, which can easily cause the crucible to crack or shatter.

Maintain Precise Temperature Control

Many chemical processes and material tests require precise temperature control to maintain stability. This is not just for accuracy but also for safety, as uncontrolled heating can accelerate reactions or damage equipment.

Understanding the Primary Risk: Thermal Shock

The single greatest danger in working with crucibles is thermal shock. Understanding this phenomenon is essential for safe handling.

What is Thermal Shock?

Thermal shock is the stress placed on a material when different parts of it expand or contract at different rates due to rapid temperature changes. Brittle materials like ceramics and graphite are highly susceptible to this stress, leading to cracks.

How to Prevent It

The key to prevention is gradual heating and cooling. Preheating tongs prevents a sudden cold spot, and allowing a crucible to cool slowly in the furnace before moving it prevents the outer surface from contracting much faster than the inside.

Safe Post-Use and Cooling Protocols

The procedure for cooling a crucible is just as important as the procedure for heating it.

The Importance of Gradual Cooling

Never place a hot crucible on a cold surface or expose it to a cool draft. The resulting thermal shock can easily cause it to fracture.

Specific Steps for Cooling

After firing, the crucible should be allowed to cool to below 200°C before it is moved into a secondary container like a desiccator or drier.

This specific step prevents residual ash from scattering due to air convection and avoids forming a strong vacuum inside the drier, which can make the lid extremely difficult to open.

A Checklist for Safe Operation

Use these points to guide your actions based on your primary objective.

- If your primary focus is personal safety: Make wearing proper PPE—heat-resistant gloves, goggles, and a face shield—a non-negotiable habit.

- If your primary focus is preventing equipment failure: Always preheat your tongs and ensure a slow, controlled cooling process to avoid thermal shock.

- If your primary focus is ensuring process purity: Double-check that your crucible's material is chemically compatible with your melt and rated for your target temperature.

By treating crucible handling as a deliberate, controlled process, you ensure safety, accuracy, and the longevity of your equipment.

Summary Table:

| Safety Focus | Key Precaution | Primary Goal |

|---|---|---|

| Personal Safety | Wear heat-resistant gloves, goggles, and a face shield. | Protect the user from burns and splashes. |

| Equipment Longevity | Always preheat tongs and follow a gradual cooling protocol. | Prevent crucible cracking from thermal shock. |

| Process Purity | Select a crucible with correct chemical and temperature compatibility. | Ensure sample integrity and prevent contamination. |

Ensure your lab operates safely and efficiently with the right equipment.

Proper crucible handling is critical for preventing accidents and maintaining process integrity. KINTEK specializes in providing high-quality lab equipment and consumables, including crucibles designed for specific applications and temperatures. Our experts can help you select the right tools and understand the best safety practices for your needs.

Don't compromise on safety—contact our specialists today for a consultation and ensure your lab is equipped for success.

Visual Guide

Related Products

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

People Also Ask

- What is the technical value of using graphite crucibles with graphite paper liners? Optimize Zr3(Al1-xSi)C2 Synthesis

- What crucible is best for melting steel? Find the Right Crucible for Your Steel Melting Needs

- Can a crucible crack? Prevent Thermal Shock and Extend Crucible Life

- Can the same crucible be used for different metals? Avoid Costly Contamination and Crucible Failure

- What is the role of grinding spent catalysts in a ceramic crucible? Unlock 99% Leaching Recovery Rates

- What is the necessity of using ceramic crucibles in TGA for TClPhMA? Ensure Accurate Thermal Data Integrity

- Why are alumina crucibles used as containers during the tungsten diffusion coating process on diamond surfaces?

- Why are Platinum/Gold (Pt/Au) crucibles selected for silver phosphate glass? Ensure Maximum Purity in Glass Synthesis