The most critical safety precautions for using a grinder are to always use personal protective equipment (PPE), especially full-face protection, and to ensure the safety guard is correctly in place. You must also select a grinding or cutting wheel with an RPM rating that exceeds the maximum RPM of your tool and inspect it for damage before every use. Never operate the grinder in a way that could cause the wheel to bind or pinch in the workpiece.

A grinder is a uniquely dangerous tool because it stores immense rotational energy and is designed to violently disintegrate material. True safety isn't just a checklist; it's a deep respect for that energy and a commitment to never defeating the tool's built-in safety mechanisms.

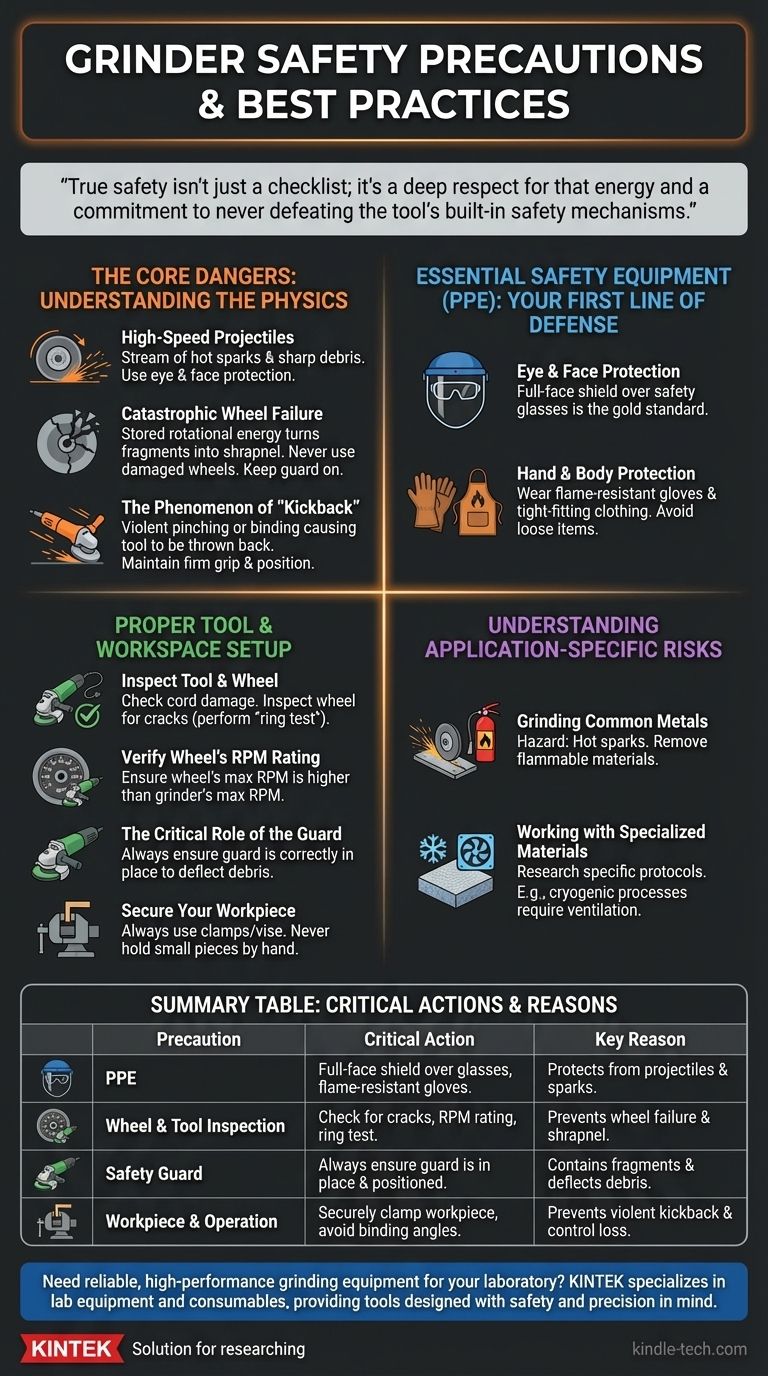

The Core Dangers: Understanding the Physics of Grinding

To use a grinder safely, you must first understand the forces you are attempting to control. The primary dangers stem from the tool's high rotational speed.

High-Speed Projectiles

A grinder wheel rotates at thousands of revolutions per minute (RPM). It removes material by force, throwing a stream of hot sparks and sharp debris away from the workpiece at high velocity.

Without proper eye and face protection, these particles can cause severe, life-altering injuries.

Catastrophic Wheel Failure

If an abrasive wheel is dropped, cracked, or used improperly, it can shatter during operation. The stored rotational energy turns the fragments into shrapnel, effectively creating a small explosion.

This is why you must never use a damaged wheel and always keep the guard in place. The guard is designed to contain these fragments and direct them away from you.

The Phenomenon of "Kickback"

Kickback occurs when the rotating wheel suddenly and violently pinches, jams, or binds in the workpiece. The rotational energy of the motor is transferred instantly, causing the entire tool to be thrown back at the operator with extreme force.

This is a primary cause of severe lacerations and is most common when using cutting wheels. Maintaining a firm grip and proper positioning is essential to manage this risk.

Essential Safety Equipment (PPE): Your First Line of Defense

Personal Protective Equipment is not optional. It is the absolute minimum requirement for operating a grinder safely.

Eye and Face Protection

A full-face shield over safety glasses is the gold standard. Safety glasses alone do not protect your face and neck from high-velocity sparks and debris.

Hand and Body Protection

Wear leather or other flame-resistant gloves to protect against sparks and sharp edges. Avoid loose-fitting clothing, jewelry, or anything that could become entangled in the spinning wheel.

Heavy-duty, non-synthetic fabrics like leather or thick cotton are recommended to protect your body from hot sparks.

Proper Tool and Workspace Setup

Correctly preparing your tool and workspace is a proactive measure that prevents most common accidents.

Inspect the Tool and Wheel

Before plugging it in, inspect the grinder's power cord for any frays or damage.

Most importantly, inspect the abrasive wheel for cracks, chips, or any signs of damage. Perform a "ring test" on new wheels by tapping them lightly; a dull thud instead of a clear ring can indicate a hidden crack.

Verify the Wheel's RPM Rating

Ensure the maximum RPM listed on the wheel is higher than the maximum RPM of your grinder. Using a wheel on a tool that spins too fast is a primary cause of wheel failure.

The Critical Role of the Guard

The wheel guard is the single most important safety feature on the grinder. It must always be in place and positioned to deflect debris and wheel fragments away from your body. Never operate a grinder without its guard.

Secure Your Workpiece

Always use clamps or a vise to firmly secure the material you are working on. Trying to hold a small piece by hand while operating a powerful grinder is a recipe for disaster.

Understanding Application-Specific Risks

Different materials and tasks present unique hazards that require special consideration.

Grinding Common Metals

The primary hazard is hot sparks, which are small pieces of burning metal. Be aware of your surroundings and remove any flammable materials like sawdust, oily rags, or fuel cans from the immediate area.

Working with Specialized Materials

Certain materials require specialized procedures. For example, some industrial processes for grinding plastics require the material to be frozen with cryogenic liquid.

This is done to make the material brittle enough to grind effectively. In these sealed environments, precautions like venting are necessary to prevent a dangerous pressure buildup or explosion. This highlights the need to understand your specific material and process.

Making the Right Choice for Your Goal

Your approach to safety should be informed by the specific task you are performing.

- If your primary focus is any task at all: Always begin with a full inspection of the tool, wheel, and power cord, and wear your full-face shield and appropriate PPE.

- If your primary focus is cutting metal: Pay extremely close attention to your body position and the angle of the tool to prevent the cutting wheel from pinching or binding, which can cause violent kickback.

- If your primary focus is grinding unusual materials: You must research and follow the specific, established safety protocols for that material, as they may involve risks like explosions or chemical reactions that are not present with common metals.

Ultimately, preparation and a fundamental respect for the tool's power are the keys to using a grinder safely and effectively.

Summary Table:

| Precaution | Critical Action | Key Reason |

|---|---|---|

| Personal Protective Equipment (PPE) | Wear a full-face shield over safety glasses and flame-resistant gloves. | Protects from high-speed projectiles and hot sparks. |

| Wheel & Tool Inspection | Check for cracks, ensure RPM rating exceeds tool's max RPM, and perform a ring test. | Prevents catastrophic wheel failure and shrapnel. |

| Safety Guard | Always ensure the guard is correctly in place and positioned. | Contains wheel fragments and deflects debris away from the user. |

| Workpiece & Operation | Securely clamp the workpiece and avoid angles that cause binding. | Prevents violent kickback and loss of control. |

Need reliable, high-performance grinding equipment for your laboratory? KINTEK specializes in lab equipment and consumables, providing tools designed with safety and precision in mind. Let our experts help you select the right grinder and accessories to ensure your lab's efficiency and, most importantly, the safety of your team. Contact KINTEK today to discuss your laboratory needs!

Visual Guide

Related Products

- Laboratory High Throughput Tissue Grinding Mill Grinder

- Laboratory Jar Ball Mill with Alumina Zirconia Grinding Jar and Balls

- Laboratory Hybrid Tissue Grinding Mill

- Laboratory Disc Cup Vibratory Mill for Sample Grinding

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill with Screw Feeder

People Also Ask

- How much balls should be loaded in a ball mill for working? Optimize Grinding with the Correct Ball Charge

- How many balls are needed for a ball mill? Optimize grinding with the right charge volume.

- What is the speed range of a ball mill? Find Your Optimal Grinding Efficiency

- What are the possible sources of contamination during sample preparation? A Guide to Protecting Your Data

- What are environmental impacts of biomass? Balancing Sustainability with Potential Harm