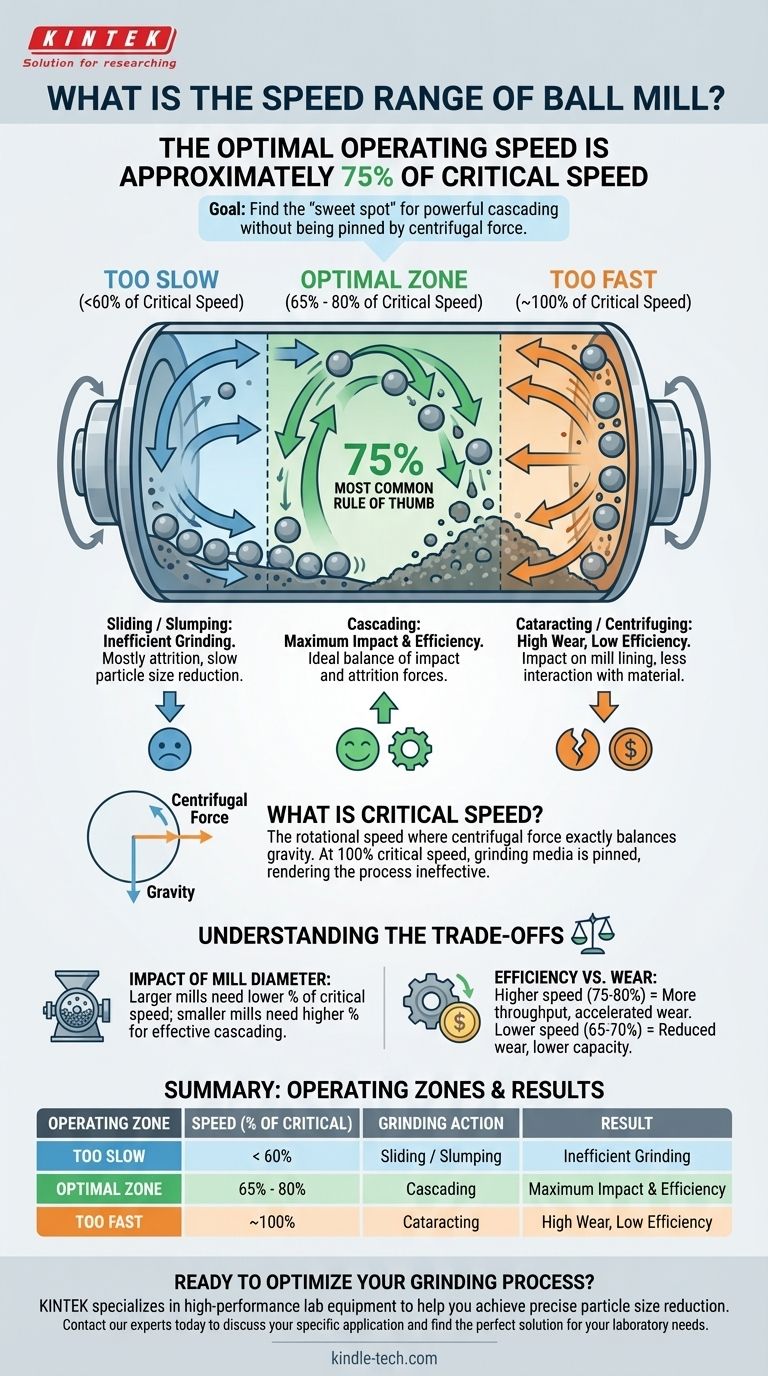

The optimal operating speed for most ball mills is approximately 75% of their "critical speed." This isn't an arbitrary number; it represents a carefully calculated balance point between the physical forces required for efficient grinding and the point where those forces become counterproductive. The ideal speed ensures the grinding media cascades effectively to crush the material.

The core challenge in setting ball mill speed is not to maximize rotation, but to optimize impact. The goal is to find the "sweet spot" where the grinding media is lifted high enough to create a powerful cascade, but not so fast that it gets pinned to the mill wall by centrifugal force.

What is Critical Speed?

Critical speed is a foundational concept in ball mill operation. It defines the theoretical limit at which the mill is effective.

Defining Critical Speed

Critical speed is the rotational speed where the centrifugal force inside the mill exactly balances the force of gravity.

At this speed, the grinding media (the balls) are pinned against the inner wall of the rotating drum. Instead of tumbling and crushing the material, they simply spin with the mill, rendering the grinding process ineffective.

Think of it like the spin cycle in a washing machine. Once it reaches a high enough speed, the clothes stick to the side of the drum. This is exactly what happens to the grinding media at 100% critical speed.

The Three Operating Speed Zones

Understanding critical speed allows us to define three distinct operational zones, only one of which is effective for grinding.

Too Slow (Below ~60% of Critical Speed)

If the mill rotates too slowly, the balls are not lifted high enough along the side of the drum.

They simply roll over each other at the bottom of the charge, a motion known as "sliding" or "slumping." This results in very little impact force and primarily causes attrition, leading to extremely inefficient and slow grinding.

The Optimal Zone (65% - 80% of Critical Speed)

This is the target range for efficient grinding, with 75% being the most common rule of thumb.

In this zone, the balls are carried almost to the top of the drum before they break away and tumble down onto the material below. This "cascading" motion maximizes the impact and attrition forces needed for effective particle size reduction.

Too Fast (Approaching 100% of Critical Speed)

As the speed increases beyond the optimal zone, the balls are thrown further and with more force. This is called "cataracting."

While this creates high impact, it directs that force primarily onto the mill's inner lining rather than the material itself. This dramatically increases wear and tear on the mill and reduces grinding efficiency as the balls spend less time interacting with the material charge.

Understanding the Trade-offs

The 75% rule is a starting point, not an absolute law. The true optimum speed is a balance between productivity and operational costs.

The Impact of Mill Diameter

The ideal percentage of critical speed is influenced by the mill's diameter.

Larger diameter mills can achieve the necessary lift height at a slightly lower percentage of critical speed. Conversely, smaller mills may need to operate at a slightly higher percentage to get the same effective cascading action.

Efficiency vs. Wear

Operating at the higher end of the optimal range (e.g., 75-80%) can increase throughput but will also accelerate the wear on both the grinding media and the mill liners.

Running at the lower end (e.g., 65-70%) reduces wear and operational costs but may result in lower production capacity.

Making the Right Choice for Your Goal

Selecting the correct speed is about aligning the mill's operation with your primary business objective.

- If your primary focus is maximum throughput: Operate toward the higher end of the optimal range (75-80% of critical speed), but plan for higher maintenance costs and more frequent replacement of liners and media.

- If your primary focus is minimizing operational costs: Run closer to the lower end of the optimal range (65-70% of critical speed) to extend the life of your equipment and consumables.

- If you are establishing a new process: Start with the industry standard of 75% of critical speed and carefully monitor your output quality and equipment wear to fine-tune your operation.

Ultimately, ball mill speed is the primary lever you can pull to balance productivity against long-term operational expense.

Summary Table:

| Operating Zone | Speed (% of Critical) | Grinding Action | Result |

|---|---|---|---|

| Too Slow | < 60% | Sliding/Slumping | Inefficient Grinding |

| Optimal Zone | 65% - 80% | Cascading | Maximum Impact & Efficiency |

| Too Fast | ~100% | Cataracting | High Wear, Low Efficiency |

Ready to optimize your grinding process? The right ball mill speed is critical for balancing productivity and operational costs. KINTEK specializes in high-performance lab equipment, including ball mills, to help you achieve precise particle size reduction and maximize your lab's efficiency. Contact our experts today to discuss your specific application and find the perfect solution for your laboratory needs.

Visual Guide

Related Products

- Laboratory Jar Ball Mill with Alumina Zirconia Grinding Jar and Balls

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the difference between a ball mill and a tumbling mill? A Guide to Grinding Equipment Types

- What is the function of an industrial grinding mill in the pretreatment of sisal residue? Optimize Bio-Thermal Conversion

- What types of mills are used for dry and wet grinding? Ball Mills vs. Hammermills Explained

- What is a dispersion mill? Unlock the Power of High-Shear Mixing for Fine Suspensions

- What is the function of the ball milling process in preparing Ti3SiC2 reaction powders? Achieving Material Homogeneity

- How to increase the efficiency of a ball mill? Optimize Speed, Feed, and Grinding Media for Peak Performance

- What is the necessity of using an industrial-grade high-shear homogenizer for biomass washing? Ensure Process Efficiency

- How much balls should be loaded in a ball mill for working? Optimize Grinding with the Correct Ball Charge