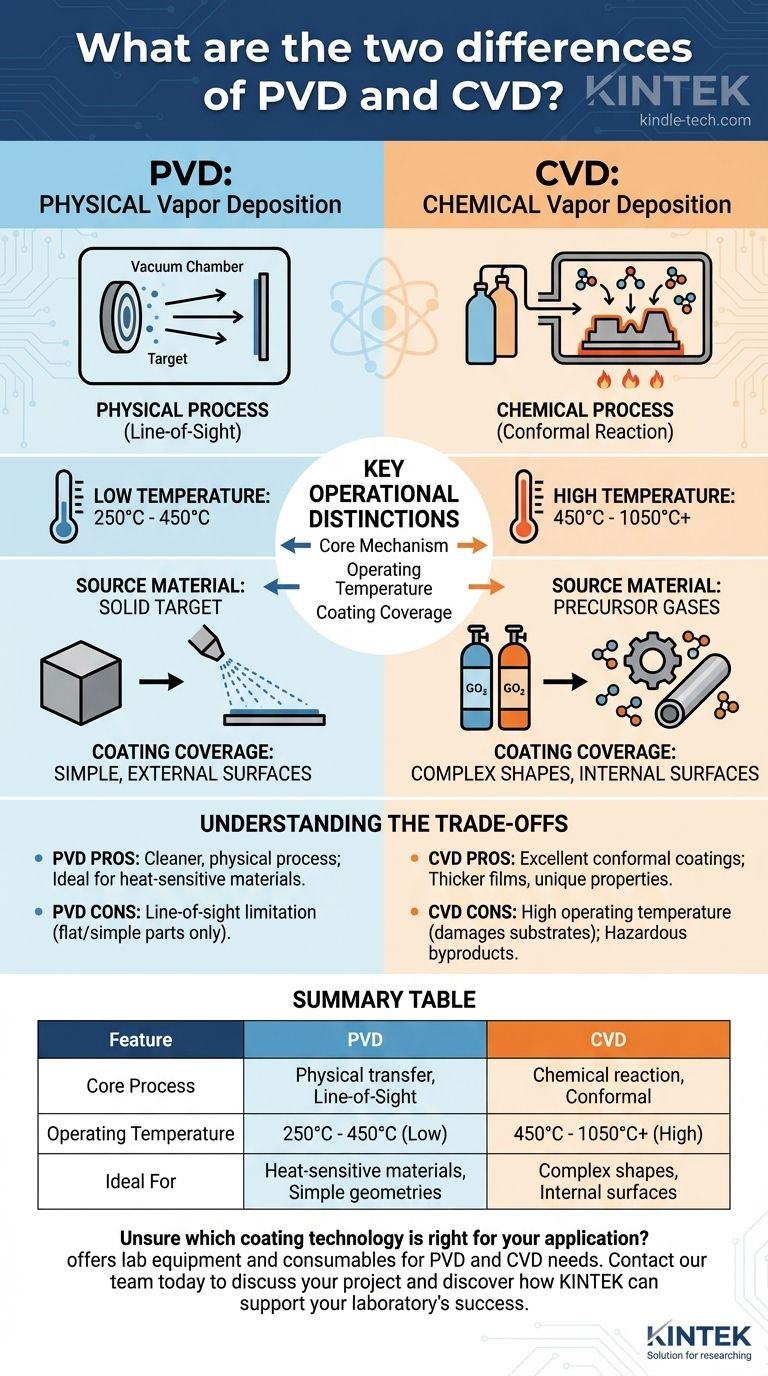

In simplest terms, the two fundamental differences between Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) lie in their core mechanism and operating temperature. PVD is a physical process that deposits a vaporized solid material onto a substrate at lower temperatures, while CVD is a chemical process that uses precursor gases to create a solid layer through reactions at much higher temperatures.

While both PVD and CVD create high-performance thin films, the choice between them is dictated by the material being coated and the geometry of the part. PVD's lower temperature is ideal for heat-sensitive substrates, whereas CVD's chemical nature provides superior coverage on complex shapes.

The Fundamental Process: Physical vs. Chemical

The most critical distinction between these two technologies is how the coating is created. One is a physical state change, while the other is a true chemical reaction.

Physical Vapor Deposition (PVD): A "Line-of-Sight" Transfer

In PVD, a solid source material (known as a "target") is vaporized inside a vacuum chamber. This vapor then travels in a straight line and condenses on the substrate, forming a thin, solid film.

Think of it like spray painting. The paint particles travel directly from the nozzle to the surface they hit. This is a line-of-sight process, meaning surfaces not directly exposed to the vapor source will not get coated effectively.

Chemical Vapor Deposition (CVD): A Conformal Chemical Reaction

In CVD, one or more volatile precursor gases are introduced into a reaction chamber. When these gases come into contact with a heated substrate, they react or decompose, forming a solid material that gets deposited as the coating.

This is more like baking a cake. The heat transforms the liquid batter (gases) into a solid (coating) that conforms perfectly to every nook and cranny of the pan (substrate). Because the gas molecules surround the part, CVD is not line-of-sight and provides excellent, uniform coverage on complex geometries.

Key Operational Distinctions

The difference in process leads to several practical distinctions that determine which method is right for a given application.

Operating Temperature

PVD processes operate at relatively low temperatures, typically between 250°C and 450°C.

CVD requires significantly higher temperatures to initiate the necessary chemical reactions, usually ranging from 450°C to over 1050°C. This high heat can alter the properties of or even damage many substrate materials.

Source Materials

As their names imply, the source materials are entirely different. PVD uses solid targets of the desired coating material, which are physically vaporized. CVD uses reactive precursor gases that chemically combine to form the coating.

Coating Coverage and Geometry

PVD's line-of-sight nature makes it excellent for coating flat or simple exterior surfaces. However, it struggles to uniformly coat complex shapes, sharp corners, or internal channels.

CVD excels at creating highly conformal coatings. The reactant gases can penetrate small, complex features, ensuring a uniform layer on all surfaces, both internal and external.

Understanding the Trade-offs

Neither technology is universally superior; they represent a set of engineering trade-offs. Choosing the wrong one can lead to component failure or unnecessary expense.

The Temperature Limitation of CVD

The primary drawback of CVD is its high operating temperature. While it produces excellent, conformal coatings, it is unsuitable for materials with low melting points or those that are sensitive to heat, such as plastics, aluminum alloys, or tempered steels.

The Geometric Limitation of PVD

The main limitation of PVD is its reliance on line-of-sight deposition. For parts with complex geometries, threads, or internal bores, achieving a uniform coating is extremely difficult and often requires complex fixtures and part rotation.

Coating Properties and Byproducts

CVD films can often be grown thicker than PVD films and can sometimes offer unique properties due to the chemical reaction process. However, these reactions can also produce hazardous byproduct gases that require careful handling and disposal.

PVD is a cleaner, purely physical process contained within a vacuum, which many consider to be more environmentally friendly and safer to operate.

Making the Right Choice for Your Application

To select the correct process, you must first define your primary goal.

- If your primary focus is coating complex shapes or internal surfaces: CVD is almost always the superior choice due to its excellent conformality.

- If your primary focus is coating heat-sensitive materials (like plastics or certain alloys): PVD's lower operating temperature makes it the more suitable, and often only, viable option.

- If your primary focus is achieving high hardness on a simple, external surface: Both can be excellent, and the decision often depends on the specific coating material (e.g., TiN, TiCN, AlTiN) and its compatibility with the substrate.

- If your primary focus is process simplicity and environmental impact: PVD is generally considered a cleaner and more straightforward physical process with fewer hazardous byproducts.

Understanding these core differences empowers you to select the deposition technology that aligns perfectly with your material, geometry, and performance goals.

Summary Table:

| Feature | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Core Process | Physical transfer (line-of-sight) | Chemical reaction (conformal) |

| Operating Temperature | 250°C - 450°C (Low) | 450°C - 1050°C+ (High) |

| Ideal For | Heat-sensitive materials, simple geometries | Complex shapes, internal surfaces |

Unsure which coating technology is right for your application?

At KINTEK, we specialize in providing the ideal lab equipment and consumables for your specific coating needs. Whether you require PVD's low-temperature precision for delicate materials or CVD's superior coverage for complex parts, our experts can help you select the perfect solution to enhance performance and durability.

Contact our team today to discuss your project and discover how KINTEK can support your laboratory's success.

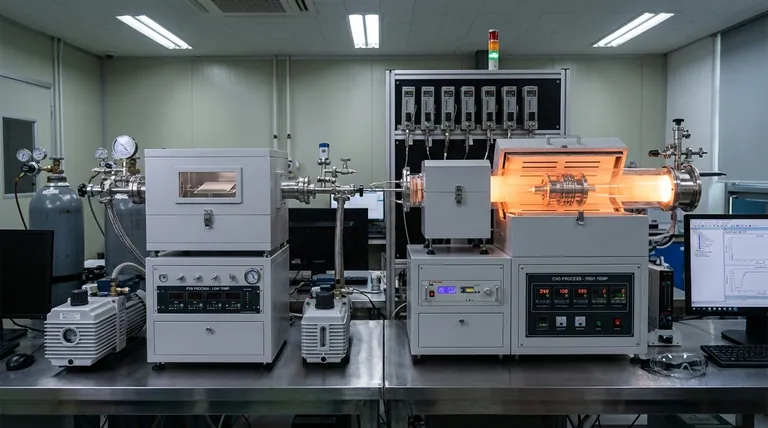

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- Why is PECVD better than CVD? Achieve Superior Low-Temperature Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What are the examples of CVD method? Discover the Versatile Applications of Chemical Vapor Deposition

- What are the advantages of PECVD over CVD? Achieve High-Quality Thin Films at Lower Temperatures

- What is the precursor gas in PECVD? The Key to Low-Temperature Thin Film Deposition