In short, pyrolysis fuel is used as a direct substitute for conventional fuel oil in stationary industrial applications. This includes powering boilers and furnaces in sectors like steel, iron, and ceramics, as well as running generators for electricity production.

The core value of pyrolysis lies not in creating a single perfect fuel, but in its ability to convert waste materials into a suite of useful products. While the resulting pyrolysis oil has practical uses, its technical limitations mean it is best suited for less sensitive industrial heating systems rather than refined engines.

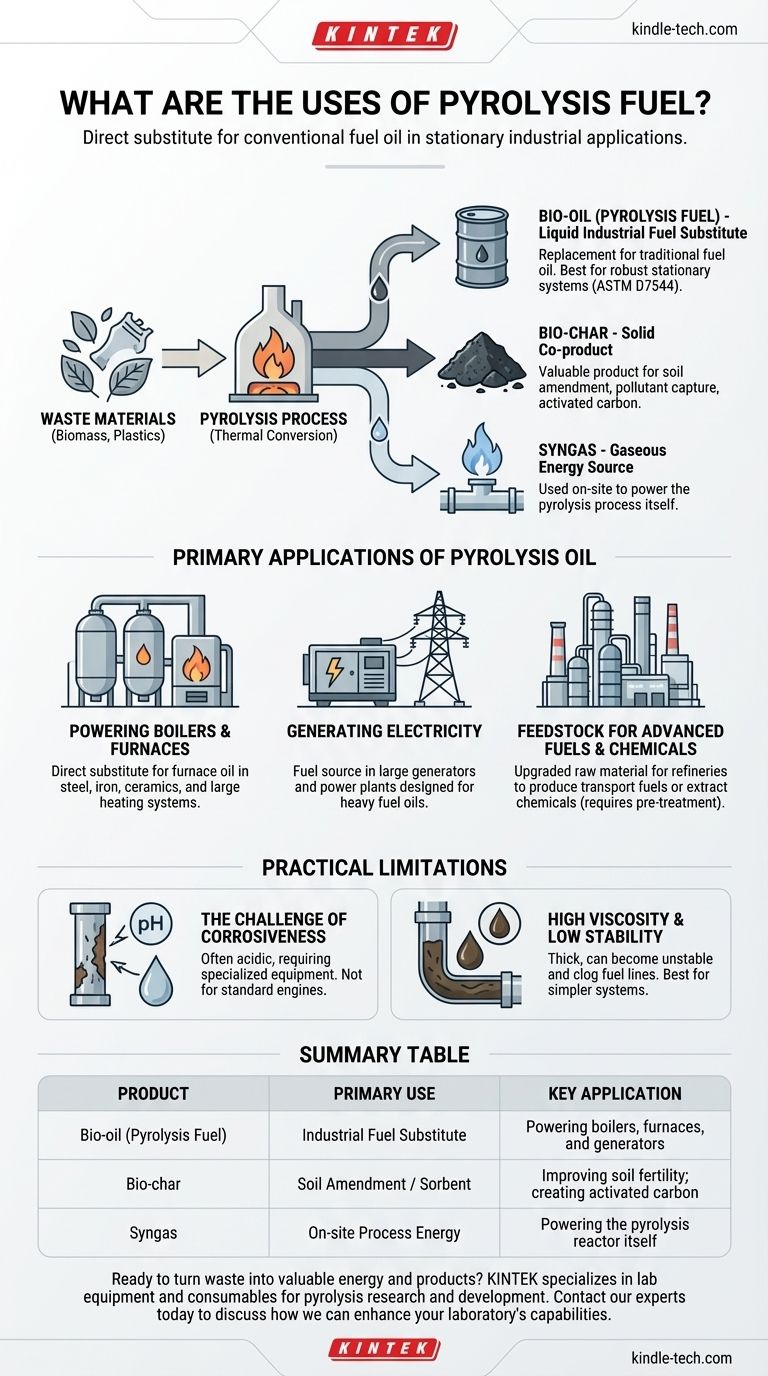

Beyond a Single Fuel: The Three Products of Pyrolysis

To understand the uses of "pyrolysis fuel," it's critical to recognize that the process creates three distinct products from a single feedstock, such as biomass or other waste materials.

Bio-oil: The Industrial Fuel Substitute

Bio-oil, also known as pyrolysis oil, is the liquid product most people refer to as pyrolysis fuel. It serves as a replacement for traditional fuel oil.

Its primary role is in stationary applications where its unique properties are less of a concern. The international standard ASTM D7544 helps regulate its use in these contexts.

Bio-char: The Valuable Solid Co-product

Bio-char is the solid, charcoal-like material left over from pyrolysis. It is not simply waste; it is a valuable product in its own right.

Applications include use as a soil amendment to improve fertility, a sorbent for capturing pollutants, or as a feedstock for producing activated carbon.

Syngas: The Gaseous Energy Source

Pyrolysis also produces a mixture of combustible gases known as syngas.

This gas is typically captured and used on-site to provide the energy needed to power the pyrolysis process itself, making the operation more self-sufficient and energy-efficient.

Primary Applications of Pyrolysis Oil

While part of a larger system, the liquid bio-oil has several defined industrial uses.

Powering Industrial Boilers and Furnaces

The most common application for pyrolysis oil is as a fuel for large-scale heating.

Industries like steel and iron foundries, boiler factories, and ceramics producers can use it as a direct substitute for furnace oil to generate process heat. Hotels and large restaurants can also use it for their heating systems.

Generating Electricity

Pyrolysis oil can be used as a fuel source in large generators and power plants designed to run on heavy fuel oils. This provides a method for converting waste biomass directly into electricity.

A Feedstock for Advanced Fuels and Chemicals

A more advanced application involves using pyrolysis oil as a raw material for existing refineries.

With significant pre-treatment and upgrading, it can be processed to produce more conventional hydrocarbon transportation fuels or be used to extract valuable chemicals.

Understanding the Practical Limitations

Objectivity requires acknowledging that pyrolysis oil is not a direct, universal replacement for all fossil fuels. Its industrial use is constrained by several technical challenges.

The Challenge of Corrosiveness

Pyrolysis oil is often acidic, which can make it corrosive to standard pipes, tanks, and engine components. This requires specialized or modified equipment for long-term use.

Issues with High Viscosity and Low Stability

Compared to diesel, pyrolysis oil has a high viscosity (it is thick) and can be unstable over time, leading to polymerization and sludge formation.

These properties can clog fuel lines and injectors, particularly in more sensitive equipment like standard diesel engines. This is a primary reason its use is concentrated in simpler, more robust stationary systems.

Making the Right Choice for Your Goal

Understanding these applications and limitations allows you to align the technology with a specific objective.

- If your primary focus is industrial heat and power: Pyrolysis oil is a viable substitute for furnace oil, especially in robust, stationary systems like industrial boilers where its corrosive nature can be managed.

- If your primary focus is waste valorization: The true strength of pyrolysis is converting low-value waste biomass or plastics into multiple valuable outputs: oil for energy, char for agriculture, and syngas for process efficiency.

- If your primary focus is transportation fuel: Raw pyrolysis oil is not a drop-in solution and requires significant investment in upgrading and refining before it can be used in modern diesel or gasoline engines.

Ultimately, viewing pyrolysis not just as a fuel source but as a complete waste-to-value system reveals its true potential.

Summary Table:

| Product | Primary Use | Key Application |

|---|---|---|

| Bio-oil (Pyrolysis Fuel) | Industrial Fuel Substitute | Powering boilers, furnaces, and generators |

| Bio-char | Soil Amendment / Sorbent | Improving soil fertility; creating activated carbon |

| Syngas | On-site Process Energy | Powering the pyrolysis reactor itself |

Ready to turn waste into valuable energy and products? KINTEK specializes in lab equipment and consumables for pyrolysis research and development. Whether you're exploring bio-oil applications or optimizing char production, our solutions support your waste valorization goals. Contact our experts today to discuss how we can enhance your laboratory's capabilities.

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- FS Electrochemical Hydrogen Fuel Cells for Diverse Applications

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

People Also Ask

- What is the meaning of rotary furnace? Achieve Superior Uniformity in Continuous Heat Treatment

- What is the drying zone in a rotary kiln? Boost Efficiency with Modern Drying Solutions

- What is the principle of rotary kiln? Mastering Continuous Thermal Processing

- How are composites processed using sintering? Engineered Material Solutions Through Advanced Thermal Bonding

- How is the operational mode of bed motion selected for a rotary kiln? Optimize Heat Transfer and Material Homogeneity