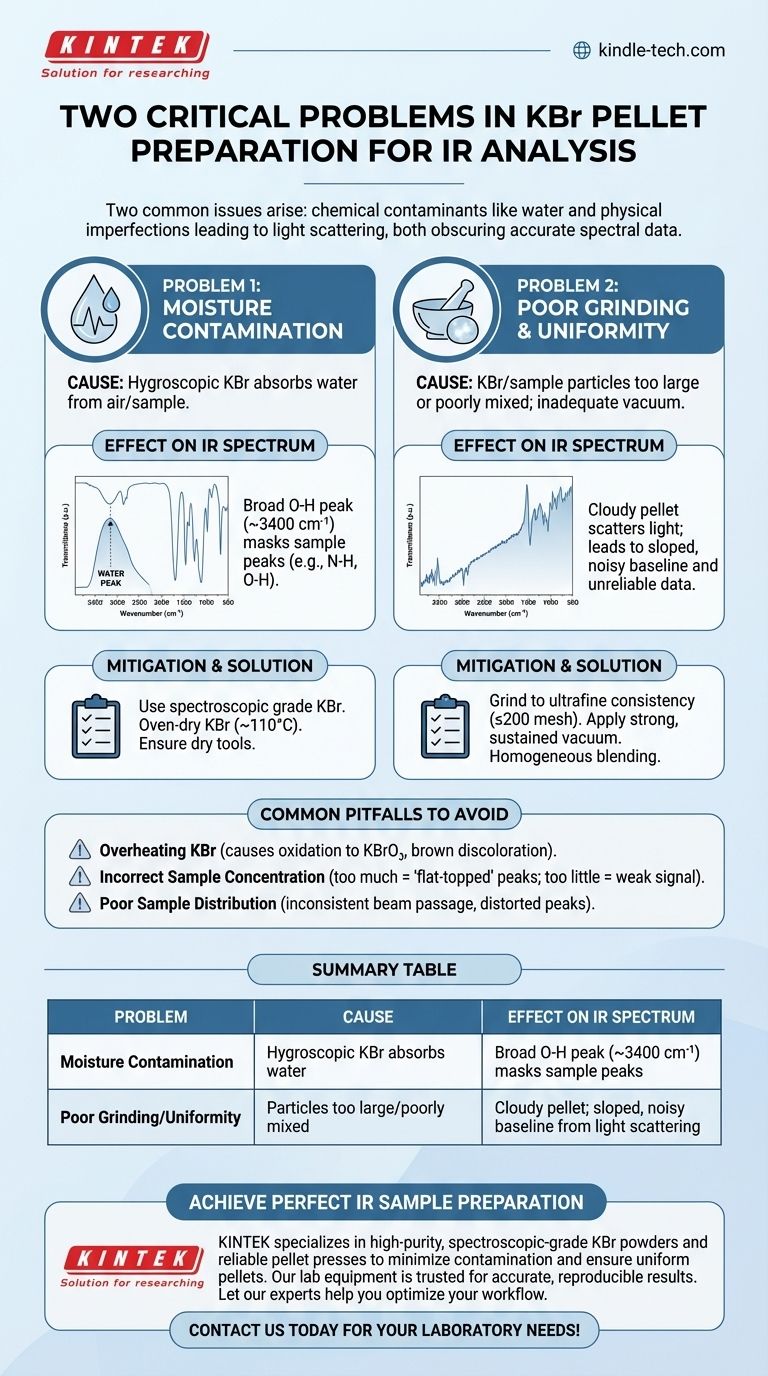

In preparing a KBr pellet for IR analysis, two of the most common and critical problems are moisture contamination and poor sample grinding. Moisture contamination introduces interfering spectral peaks, primarily from water's broad O-H bond, which can obscure the sample's true signal. Poor grinding or mixing results in a cloudy, non-uniform pellet that scatters infrared light, leading to a sloped, noisy baseline and unreliable data.

The ultimate goal of KBr pellet preparation is to create an optically transparent matrix that is invisible to the IR spectrometer. Therefore, the most significant problems arise from two sources: chemical contaminants like water that absorb IR light, and physical imperfections that scatter it.

The Problem of Chemical Contamination

The most frequent chemical contaminant in KBr pellet preparation is water. Potassium bromide (KBr) is highly hygroscopic, meaning it readily absorbs moisture from the atmosphere.

Why Moisture is the Primary Culprit

Water has a very strong, broad absorption band in the infrared spectrum, typically centered around 3400 cm⁻¹.

This O-H stretching vibration can easily overlap with or completely mask important functional groups in your sample, such as N-H or O-H stretches, making your results difficult or impossible to interpret.

Sources of Water Contamination

Moisture can be introduced from the KBr powder itself if it hasn't been properly stored or dried. It can also come from a sample that is not completely dry or simply from ambient humidity during the grinding and pressing process.

Mitigating Moisture

To prevent this, the KBr powder must be of spectroscopic grade and should be dried in an oven at approximately 110°C for several hours before use. All tools, including the mortar, pestle, and die set, must be scrupulously clean and dry.

The Challenge of Physical Uniformity

An ideal KBr pellet is perfectly clear and transparent. A cloudy or opaque appearance is a clear indicator of a physical problem that will degrade the quality of your spectrum.

The Principle of Light Scattering

This cloudiness is caused by light scattering. When the particle sizes of the KBr or sample are similar to the wavelength of the infrared light, the light is scattered in multiple directions instead of passing straight through to the detector.

This phenomenon, known as the Christiansen effect, results in a significantly sloped and noisy baseline, reducing the accuracy of your measurement.

Cause 1: Insufficient Grinding

The primary cause of scattering is KBr or sample particles that are too large. The powder must be ground to an extremely fine, consistent size, often specified as 200 mesh or smaller.

This ensures the particle size is much smaller than the IR wavelengths being used, minimizing scattering and allowing light to pass through unimpeded.

Cause 2: Inadequate Vacuum

During the pressing stage, applying a strong and sustained vacuum is critical. Air trapped within the powder creates tiny pockets with a different refractive index than the KBr.

These pockets act as scattering centers, contributing to a cloudy pellet and a poor baseline. Inadequate vacuum can also lead to a fragile pellet that cracks or breaks easily.

Common Pitfalls to Avoid

Beyond the two main issues, several other procedural errors can compromise your results. Understanding these will help you troubleshoot a wider range of problems.

The Risk of Overheating KBr

While drying KBr is essential, rapid or excessive heating should be avoided. Overheating can cause the potassium bromide (KBr) to oxidize into potassium bromate (KBrO₃).

This chemical change often results in a brown discoloration of the pellet and can introduce its own unwanted spectral artifacts.

Incorrect Sample Concentration

The ratio of sample to KBr is critical. Using too much sample will result in absorption peaks that are too intense, often becoming "flat-topped" as they exceed the detector's linear range (total absorption).

Conversely, using too little sample will produce a weak signal with a poor signal-to-noise ratio, making it difficult to identify small or subtle peaks.

Poor Sample Distribution

Simply mixing the sample and KBr is not enough; they must be homogeneously blended. If the sample is concentrated in small clumps within the pellet, the IR beam will pass through inconsistently, distorting peak shapes and relative intensities.

Making the Right Choice for Your Goal

Your preparation technique should be guided by the specific goal of your analysis.

- If your primary focus is a flat, clean baseline: Prioritize ultra-fine grinding of your KBr and sample, and apply a strong, sustained vacuum to minimize light scattering.

- If your primary focus is avoiding false peaks: Ensure your KBr is spectroscopic grade and has been meticulously dried to eliminate the broad, interfering signal from water.

- If your primary focus is quantitative accuracy: Both physical uniformity and chemical purity are non-negotiable, as scattering and contamination will ruin the reliability of your measurements.

Ultimately, a successful KBr pellet is an invisible one, allowing only your sample's unique spectral fingerprint to be seen.

Summary Table:

| Problem | Cause | Effect on IR Spectrum |

|---|---|---|

| Moisture Contamination | Hygroscopic KBr absorbs water from air or sample | Broad O-H peak (~3400 cm⁻¹) masks sample peaks (N-H, O-H) |

| Poor Grinding/Uniformity | KBr/sample particles are too large or poorly mixed | Cloudy pellet; sloped, noisy baseline from light scattering |

Achieve perfect IR sample preparation every time. KINTEK specializes in high-purity, spectroscopic-grade KBr powders and reliable pellet presses designed to minimize contamination and ensure uniform pellets. Our lab equipment and consumables are trusted by researchers who demand accurate, reproducible results. Let our experts help you optimize your workflow—contact us today to discuss your laboratory needs!

Visual Guide

Related Products

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- kbr pellet press 2t

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What is a KBr press? Creating Transparent Pellets for Accurate FT-IR Analysis

- What are the advantages of press forging over hammer forging? Achieve Superior Internal Integrity

- Why is a laboratory hydraulic press required for solid-state battery assembly? Essential Tools for Ion Conductivity

- What was wrong with the hydraulic press? Key Drawbacks in Maintenance and Safety

- How is a laboratory hydraulic press used in the fabrication of graphite-cement composite electrodes?

- What are the safety precautions of hydraulic system? Essential Guidelines to Prevent Catastrophic Failure

- What is the role of a hydraulic pellet press in preparing vanadium-titanium magnetite? Optimize Densification & Reactivity

- What role does a laboratory hydraulic press play in the assembly of solid-state batteries? Achieve Optimal Ion Flow