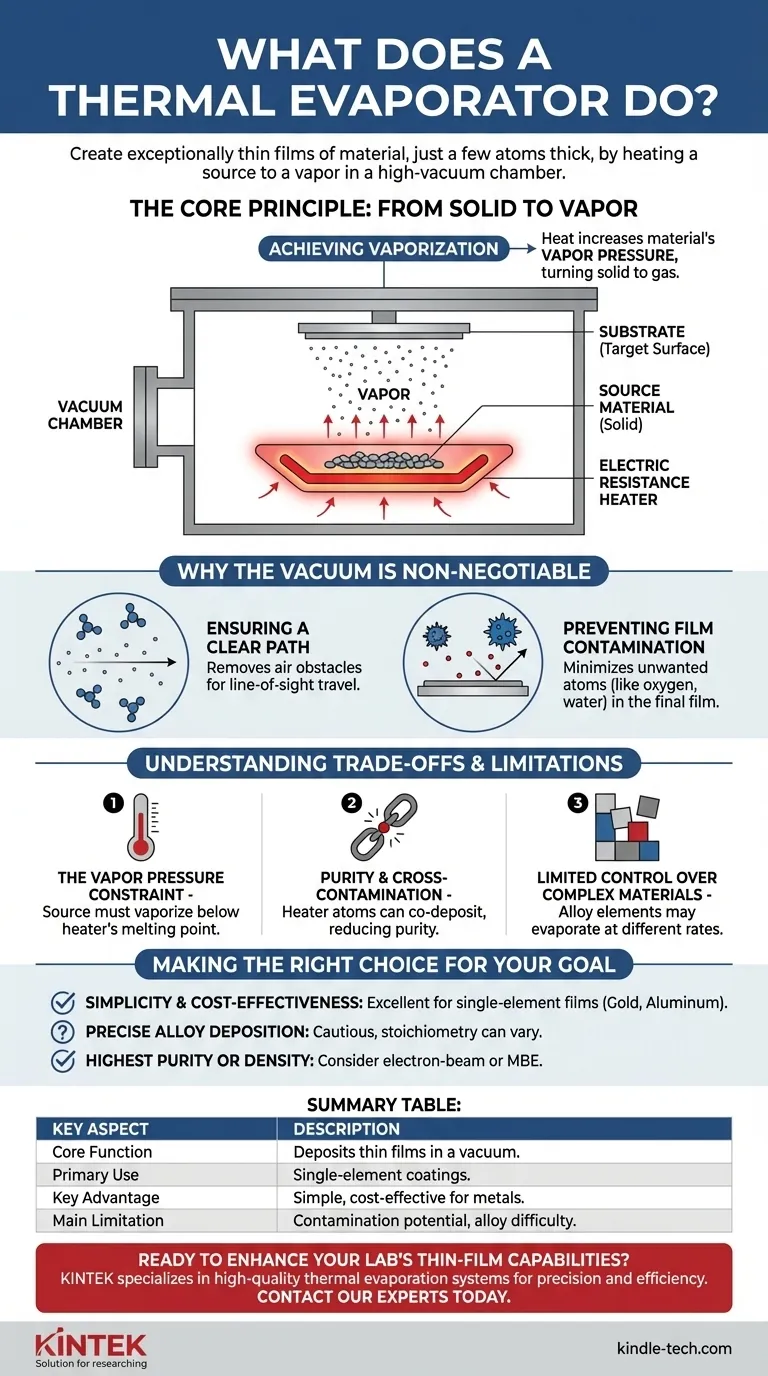

At its core, a thermal evaporator is a system used to create exceptionally thin films of material, often just a few atoms thick. It accomplishes this by heating a source material inside a high-vacuum chamber until it turns into a vapor, which then travels and condenses onto a target surface, known as a substrate.

A thermal evaporator fundamentally controls a material's phase change from solid to vapor. It uses heat to create a cloud of atoms in a vacuum, allowing them to precisely coat a surface without interference from air or impurities.

The Core Principle: From Solid to Vapor

The entire process hinges on carefully managing heat and pressure to transform a solid source material into a gas that can be precisely directed.

The Role of the Heater

An electric resistance heater, often a small metallic boat or filament, is the engine of the evaporator. An electric current is passed through it, causing it to heat up significantly, much like the filament in an old incandescent lightbulb.

The source material you wish to deposit, typically in the form of pellets, wire, or powder, is placed directly onto or into this heater.

Achieving Vaporization

As the heater's temperature rises, it transfers this energy to the source material, causing it to melt. With continued heating, the material's vapor pressure increases dramatically.

Vapor pressure is the inherent tendency of a material to turn into a gas. By raising the temperature high enough, the material effectively boils and releases a vapor of its own atoms into the chamber.

Why the Vacuum is Non-Negotiable

The process is always performed inside a high-vacuum chamber. This controlled environment is not an optional feature; it is essential for two critical reasons.

Ensuring a Clear Path

At atmospheric pressure, a chamber is filled with trillions of air molecules (nitrogen, oxygen, etc.). If you tried to evaporate a material in these conditions, the vapor atoms would constantly collide with air molecules.

The vacuum removes these obstacles, creating a clear, line-of-sight path. This allows the vaporized atoms to travel unimpeded from the source directly to the substrate, ensuring an efficient and predictable coating process.

Preventing Film Contamination

The second purpose of the vacuum is to maintain purity. Gasses like oxygen and water vapor are highly reactive and can easily incorporate themselves into the growing film.

This incorporation of impurities can drastically alter the desired electrical, optical, or mechanical properties of the final film. A high vacuum minimizes the presence of these unwanted atoms, leading to a much purer deposit.

Understanding the Trade-offs and Limitations

While powerful, thermal evaporation is not a universal solution. Understanding its inherent constraints is key to using it effectively.

The Vapor Pressure Constraint

A fundamental limitation is that the source material must vaporize at a temperature lower than the melting point of the heating element.

If the heater melts or begins to vaporize before the source material does, it will contaminate the film or destroy the setup. This is why specific heater materials (like tungsten or molybdenum) are chosen for their extremely high melting points.

Purity and Cross-Contamination

While the vacuum removes atmospheric gasses, the heating element itself can be a source of contamination if operated at too high a temperature. Atoms from the heater can co-deposit with the source material.

This makes the technique less suitable for applications demanding the absolute highest levels of purity compared to other methods like electron-beam evaporation.

Limited Control Over Complex Materials

When evaporating alloys or compounds, the individual elements may have different vapor pressures. The element with the higher vapor pressure will evaporate faster, meaning the composition of the resulting film may not match the composition of the source material.

Making the Right Choice for Your Goal

Thermal evaporation is a foundational thin-film deposition technique. Here’s how to decide if it aligns with your needs.

- If your primary focus is simplicity and cost-effectiveness: Thermal evaporation is an excellent and widely used method for depositing single-element films, especially common metals like aluminum, gold, chromium, or silver.

- If your primary focus is depositing a precise alloy: You must be cautious, as the final film's stoichiometry can differ from the source. Other techniques like sputtering may offer better compositional control.

- If your primary focus is the absolute highest film purity or density: Consider more advanced methods like electron-beam evaporation or molecular beam epitaxy (MBE), which provide greater control over contamination and film structure.

It is a powerful tool that transforms bulk materials into high-performance, atomically thin surfaces.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Function | Deposits thin films of material onto a substrate in a vacuum. |

| Primary Use | Coating with single-element materials like gold, silver, and aluminum. |

| Key Advantage | Simplicity and cost-effectiveness for many metal deposition tasks. |

| Main Limitation | Potential for contamination and difficulty with precise alloy deposition. |

Ready to enhance your lab's thin-film capabilities?

KINTEK specializes in providing high-quality lab equipment, including reliable thermal evaporation systems. Whether you are depositing metals for electronics, optics, or research, our solutions are designed for precision and efficiency.

Contact our experts today to discuss your specific application and find the perfect thermal evaporator for your laboratory needs.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- E Beam Crucibles Electron Gun Beam Crucible for Evaporation

People Also Ask

- What equipment is used for evaporation? A Guide to Thermal Evaporation Systems for Thin-Film Coating

- What are the disadvantages of thermal evaporation? Key Limitations in Purity, Density & Materials

- What are thermal evaporation sources? Key Types and How to Choose the Right One

- What is thermal evaporation deposition techniques? A Simple Guide to Thin Film Coating

- What are the advantages of thermal evaporation method? Achieve Simple, Fast, and Cost-Effective Thin Films

- How does temperature affect the rate of evaporation? Master the Science for Better Lab Results

- What is the advantage of e-beam? Rapid, Material-Friendly Sterilization for Modern Labs

- What is the thickness of physical vapor deposition? Tailoring PVD Coating for Your Application