In the synthesis of carbon nanotubes, CVD stands for Chemical Vapor Deposition. It is a dominant and highly versatile "bottom-up" manufacturing technique where carbon-containing gas molecules are chemically broken down at high temperatures, using a metal catalyst to assemble carbon atoms into the cylindrical, honeycomb-like structure of a nanotube.

The core concept of CVD is not just about making nanotubes, but about growing them with precision. It treats the process like nanoscale agriculture, where controlling the environment (temperature, pressure, gas) determines the final structure and quality of the crop (the nanotubes).

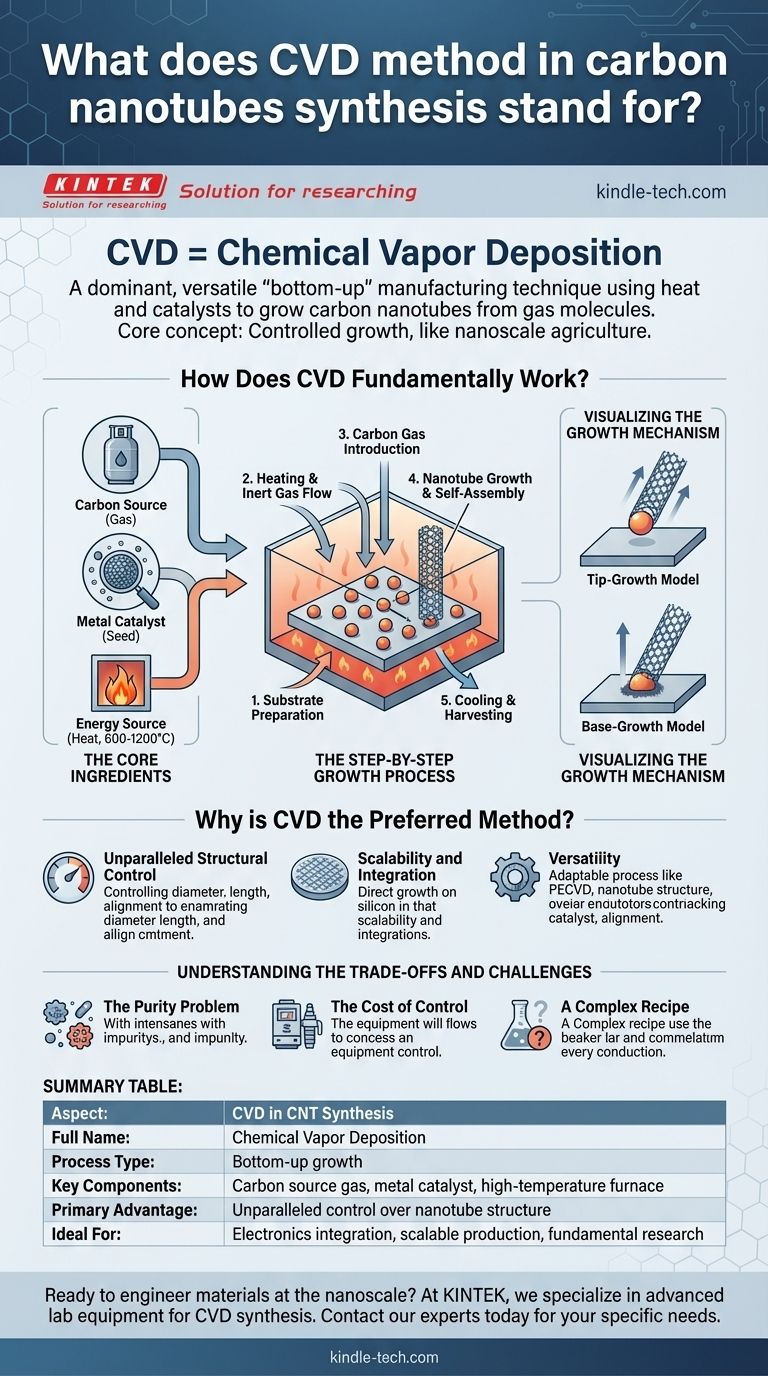

How Does CVD Fundamentally Work?

The CVD process is a carefully orchestrated chemical reaction occurring on a substrate's surface. It can be broken down into a few essential components and steps.

The Core Ingredients: Gas, Catalyst, and Heat

Think of the process like planting a seed in a specialized greenhouse.

The carbon source (typically a hydrocarbon gas like methane, ethylene, or acetylene) acts as the "nutrient-rich air." This gas provides the carbon atoms that will form the nanotube's structure.

The metal catalyst (often nanoparticles of iron, nickel, or cobalt) is the "seed." It is the critical component that cracks the hydrocarbon gas molecules and serves as the nucleation site where nanotube growth begins.

The energy source (usually a high-temperature furnace reaching 600-1200°C) is the "greenhouse environment." This intense heat provides the energy needed to break the chemical bonds in the gas and fuel the growth process.

The Step-by-Step Growth Process

First, a substrate, such as a silicon wafer, is coated with a thin layer of the metal catalyst.

Next, the substrate is placed in a furnace and heated to the target temperature while an inert gas flows through the chamber.

Then, the carbon-containing gas is introduced into the reaction chamber. At this high temperature, the catalyst particles break down the gas, and carbon atoms begin to deposit and self-assemble on the catalyst, forming the nanotube structure.

Finally, after the desired growth time, the system is cooled down, and the newly formed carbon nanotubes are ready for harvesting or analysis directly on the substrate.

Visualizing the Growth Mechanism

Two primary models describe how the nanotube emerges from the catalyst particle.

In the "tip-growth" model, the nanotube lifts the catalyst particle off the substrate, and growth continues with the catalyst at its tip.

In the "base-growth" model, the catalyst particle remains anchored to the substrate, and the nanotube grows upward from it, much like a blade of grass from the soil.

Why is CVD the Preferred Method?

While other methods like arc discharge and laser ablation exist, CVD has become the go-to technique for many applications, especially in electronics and research.

Unparalleled Structural Control

CVD offers a high degree of control. By carefully tuning parameters like temperature, gas flow rate, and pressure, researchers can influence the nanotubes' diameter, length, and even alignment.

The size of the catalyst nanoparticle, for example, directly correlates with the diameter of the nanotube that will grow from it.

Scalability and Integration

A major advantage of CVD is its ability to grow nanotubes directly onto a desired substrate, such as a silicon wafer. This is crucial for integrating nanotubes into electronic devices like transistors and sensors.

This direct-growth capability makes large-scale, uniform production feasible, bridging the gap between laboratory research and industrial manufacturing.

Versatility

The process is highly adaptable. Different variations of CVD, such as Plasma-Enhanced CVD (PECVD), allow for growth at lower temperatures, making it compatible with a wider range of substrate materials.

Understanding the Trade-offs and Challenges

Despite its strengths, CVD is not without its complexities and limitations. Understanding these is key to its successful implementation.

The Purity Problem

The resulting carbon nanotubes are often mixed with impurities. These can include amorphous (non-structured) carbon and residual metal catalyst particles, which can be difficult to remove and may degrade performance.

The Cost of Control

Achieving high-quality results requires sophisticated equipment. High-temperature furnaces, vacuum systems, and precise gas flow controllers contribute to the cost and complexity of a CVD setup.

A Complex Recipe

The final product is extremely sensitive to a multitude of process parameters. Finding the exact "recipe" to produce nanotubes with specific, repeatable properties requires significant experimentation and optimization, making it both an art and a science.

Making the Right Choice for Your Goal

Selecting a synthesis method depends entirely on the intended application of the carbon nanotubes. CVD's strengths lie in its control and potential for direct integration.

- If your primary focus is integrating CNTs into electronic devices: CVD is the definitive choice because it allows you to grow precisely located and often aligned nanotubes directly on a wafer.

- If your primary focus is fundamental research on CNT properties: CVD provides the parameter control needed to systematically study how structure (like diameter) affects electronic or mechanical behavior.

- If your primary focus is producing large, bulk quantities for composite materials: CVD is a strong candidate for its scalability, though you must factor in the need for post-growth purification steps.

By understanding CVD as a process of controlled growth, you can better leverage its power to engineer materials at the nanoscale.

Summary Table:

| Aspect | CVD in CNT Synthesis |

|---|---|

| Full Name | Chemical Vapor Deposition |

| Process Type | Bottom-up growth |

| Key Components | Carbon source gas, metal catalyst, high-temperature furnace |

| Primary Advantage | Unparalleled control over nanotube structure (diameter, length, alignment) |

| Ideal For | Electronics integration, scalable production, fundamental research |

Ready to engineer materials at the nanoscale?

At KINTEK, we specialize in providing the advanced lab equipment and consumables necessary for cutting-edge research like CVD synthesis of carbon nanotubes. Whether you are developing next-generation electronics or conducting fundamental materials science, our expertise and high-quality products support your quest for precision and control.

Let's discuss how we can equip your lab for success. Contact our experts today to find the perfect solution for your specific needs.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

People Also Ask

- How high of temperature do carbon nanotubes in air have the ability to sustain? Understanding the Oxidation Limit

- What are the main advantages of Chemical Vapor Deposition (CVD)? Achieve Precision Coating for Complex Geometries

- What are the advantages of industrial CVD for solid boriding? Superior Process Control and Material Integrity

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance

- What is the floating catalyst method? A Guide to High-Yield CNT Production