In short, the pyrolysis of wood releases a combination of solid, liquid, and gaseous products. The process breaks down the wood in a high-temperature, low-oxygen environment, yielding a carbon-rich solid known as biochar, a complex liquid called bio-oil, and a combustible gas mixture referred to as syngas.

Pyrolysis is not simple incineration; it is a controlled thermal deconstruction. The key insight is that by precisely managing process conditions like temperature, you can dictate which of these three product streams—solid, liquid, or gas—is maximized.

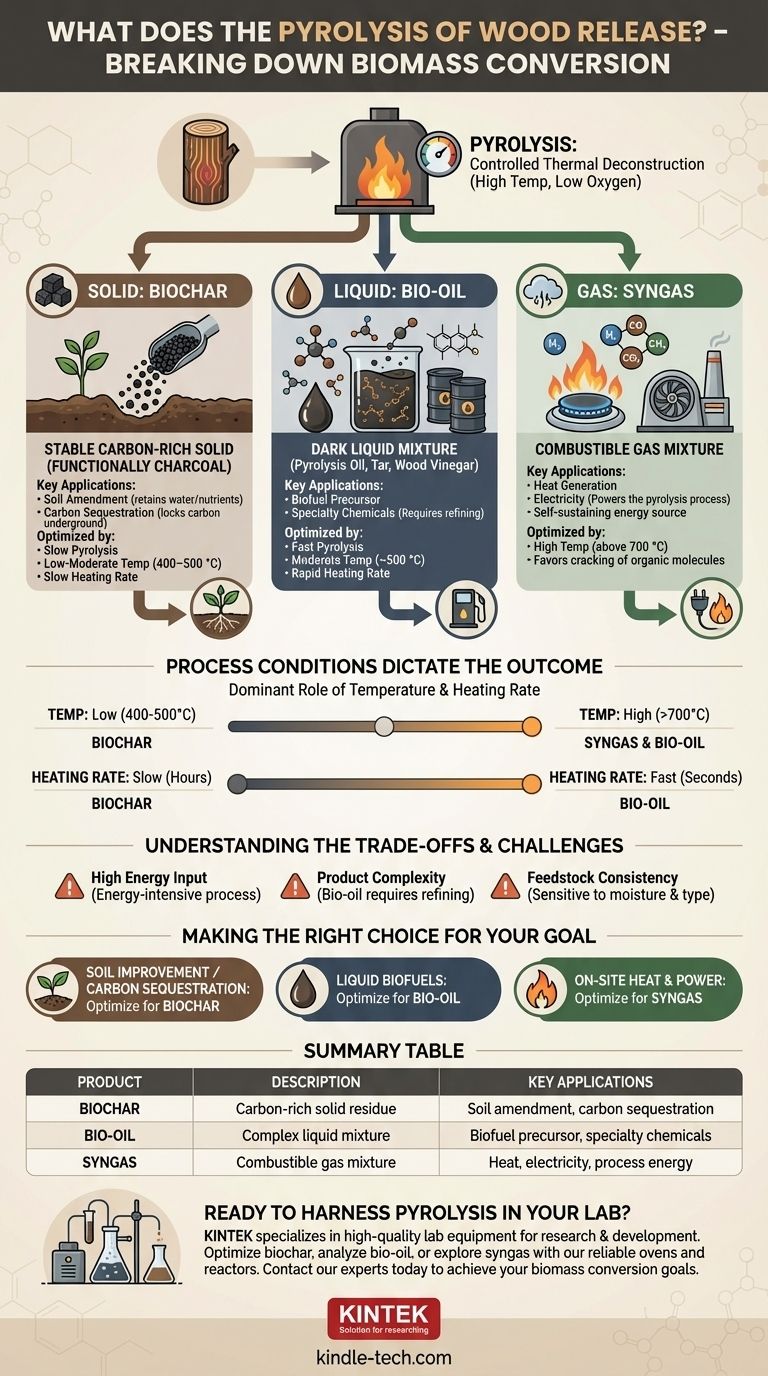

Deconstructing Wood: The Three Core Products

Wood pyrolysis separates the complex organic matter of biomass into three distinct and valuable components. Understanding each is critical to understanding the process as a whole.

The Solid: Biochar

Biochar is the stable, carbon-rich solid that remains after the volatile components of the wood have been driven off. It is functionally a form of charcoal.

Its primary modern application is as a soil amendment. The porous structure of biochar helps retain water and nutrients, improving soil health and promoting carbon sequestration by locking carbon in the ground for long periods.

The Liquid: Bio-oil

Bio-oil, also known as pyrolysis oil, is a dark, dense liquid mixture of hundreds of different organic compounds. It is a condensed form of the volatile gases and includes substances like tar and wood vinegar.

This liquid can be a precursor to biofuels and specialty chemicals. However, it is typically acidic and unstable, requiring significant refining before it can be used as a direct replacement for conventional fuels.

The Gas: Syngas

Syngas, or synthesis gas, is a mixture of combustible gases. Its primary components are hydrogen (H₂), carbon monoxide (CO), methane (CH₄), and carbon dioxide (CO₂).

This gas has immediate energy value. It can be combusted directly to generate heat and electricity, often used to power the pyrolysis process itself, creating a more self-sustaining system.

How Process Conditions Dictate the Outcome

The ratio of biochar, bio-oil, and syngas is not fixed. It is a direct result of the specific parameters used during pyrolysis, giving operators significant control over the final output.

The Dominant Role of Temperature

Temperature is the most critical variable. Different temperature ranges favor the creation of different products.

- Low to Moderate Temperatures (400–500 °C): Slower heating in this range maximizes the production of biochar, as less of the solid carbon is converted into gas.

- High Temperatures (above 700 °C): These conditions favor the "cracking" of larger organic molecules into smaller ones, maximizing the yield of syngas and bio-oil.

The Influence of Heating Rate

How quickly the wood is heated also dramatically changes the outcome. This gives rise to two main types of pyrolysis.

- Slow Pyrolysis: A slow heating rate over several hours is the ideal method for producing the highest quantity and quality of biochar.

- Fast Pyrolysis: Heating the wood very rapidly (in seconds) to a moderate temperature is the preferred method for maximizing the yield of bio-oil.

Understanding the Trade-offs

While pyrolysis offers a powerful way to convert biomass waste into valuable products, it is essential to recognize its operational challenges and limitations.

High Energy Input

Pyrolysis is an energy-intensive process. Reaching and maintaining temperatures of 500 °C or higher requires a significant initial energy investment, which must be factored into the economic and environmental calculus of any operation.

Product Complexity and Refining

The raw products are not always ready for immediate use. Bio-oil in particular is corrosive and chemically complex, requiring costly and energy-intensive upgrading to become a stable, usable transportation fuel.

Feedstock Consistency

The process is sensitive to the type and condition of the input material. The moisture content, particle size, and specific type of wood all influence the efficiency of the reaction and the final product yields.

Making the Right Choice for Your Goal

To apply pyrolysis effectively, you must align the process conditions with your primary objective.

- If your primary focus is carbon sequestration or soil improvement: Optimize for biochar production using slow pyrolysis at lower temperatures (around 400-500 °C).

- If your primary focus is producing liquid biofuels: Optimize for bio-oil production using fast pyrolysis at moderate temperatures (around 500 °C).

- If your primary focus is generating on-site heat and power: Optimize for syngas production using very high temperatures (above 700 °C).

Ultimately, pyrolysis is a flexible thermochemical tool that allows you to transform wood into the specific resources you need.

Summary Table:

| Product | Description | Key Applications |

|---|---|---|

| Biochar | Carbon-rich solid residue | Soil amendment, carbon sequestration |

| Bio-Oil | Complex liquid mixture | Biofuel precursor, specialty chemicals |

| Syngas | Combustible gas mixture (H₂, CO, CH₄) | Heat, electricity, process energy |

Ready to harness the power of pyrolysis in your lab?

KINTEK specializes in high-quality lab equipment for pyrolysis research and development. Whether you are optimizing biochar production for agricultural studies, analyzing bio-oil for fuel applications, or exploring syngas for energy generation, our reliable ovens and reactors provide the precise temperature control you need.

Contact our experts today to discuss how our solutions can help you achieve your specific biomass conversion goals.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is the temperature for activated carbon regeneration? Key Ranges from 220°C to 900°C

- Can you restore activated carbon? Understanding the Industrial Reactivation Process

- How to regenerate activated carbon? Master the 3-Stage Thermal Process for Cost Savings

- What is the temperature of a carbon regeneration kiln? Mastering the 750-800°C Reactivation Process

- What are the principles of a rotary kiln? Master the Mechanics of High-Temperature Processing