The final product size in a ball mill is determined by a precise interplay of several key operational parameters. These include the characteristics of the grinding media (its size, density, and volume), the rotational speed of the mill, the properties of the material being ground, and the rate at which you feed material into the system. Each factor influences the energy dynamics inside the mill, which is the ultimate driver of size reduction.

Controlling the final particle size is fundamentally about managing energy transfer. The size and density of the grinding media determine the impact force (energy per collision), while the mill speed and media load determine the frequency of those collisions.

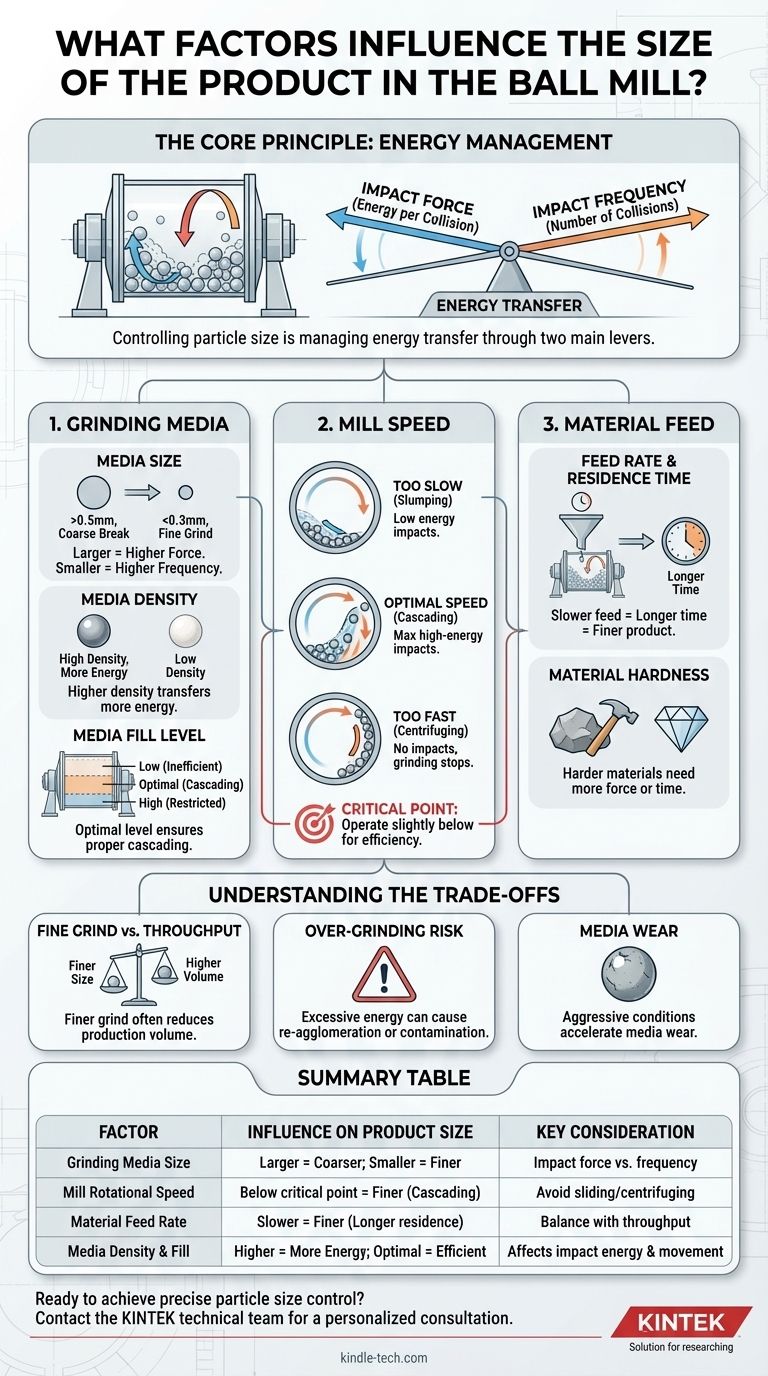

The Core Principle: Energy Management

Ball milling is a mechanical process where the goal is to transfer kinetic energy from the grinding media (the balls) to the material being processed. The more effectively this energy is delivered, the finer the resulting product.

Think of it as two distinct energy levers you can pull: impact force and impact frequency. Every adjustment you make to the mill's parameters is an attempt to balance these two forces to achieve your desired outcome.

Key Factors Controlling Product Size

Understanding how each variable affects the energy inside the mill is the key to mastering the process. These factors do not operate in isolation; they are highly interdependent.

Grinding Media: The Engine of Size Reduction

The grinding media is the most critical component for controlling the final particle size.

-

Media Size: Larger media (e.g., balls >0.5 mm) deliver higher impact force with each collision. This is ideal for breaking down large, coarse feed material. Smaller media (<0.3 mm) provide a much higher frequency of collisions, which is more effective for grinding already small particles into submicron or nano-sized powders.

-

Media Density: The material of the media matters. High-density media like steel will transfer significantly more energy upon impact than lower-density media like ceramic, even if they are the same size. Harder feed materials often require denser media.

-

Media Fill Level (Charge): The percentage of the mill's volume filled with media is crucial. A low fill level results in too few impacts, leading to inefficient grinding. An excessively high fill level restricts the movement of the media, preventing them from cascading properly and reducing the energy of each impact.

Mill Speed: Finding the Critical Point

The rotational speed of the mill dictates the behavior of the grinding media.

-

Too Slow: The media will simply slide or "slump," resulting in low-energy impacts and very little size reduction.

-

Too Fast (Centrifuging): The media will be pinned against the mill wall by centrifugal force. With no tumbling or cascading, there are no impacts, and grinding stops completely.

-

Optimal Speed: There is a "critical speed" where the media are carried to the top of the mill and then cascade down, creating the maximum number of high-energy impacts. Operating slightly below this critical speed is typically the most efficient zone for grinding.

Material Feed: Residence Time and Hardness

The properties of the material you are milling and how you introduce it into the mill directly affect the outcome.

-

Feed Rate: A slower feed rate increases the "residence time"—the average amount of time a particle spends inside the mill. Longer residence times expose particles to more impacts, resulting in a finer final product.

-

Material Hardness: Harder materials require more energy to fracture. To grind them effectively, you may need to increase the impact force by using larger or denser media, or increase the residence time by slowing the feed rate.

Understanding the Trade-offs

Optimizing for one outcome often means compromising on another. Acknowledging these trade-offs is essential for practical process control.

The Fine Grind vs. Throughput Dilemma

Achieving a very fine particle size almost always comes at the cost of production volume. Using smaller media and slowing the feed rate to increase residence time will produce a finer powder but will drastically lower the amount of material processed per hour (throughput).

The Risk of Over-Grinding

Milling for too long or with excessive energy can be counterproductive. Some materials can begin to re-agglomerate after reaching a certain fineness. This can also introduce excess heat or cause unwanted chemical changes in sensitive materials.

Media Wear and Contamination

Aggressive milling conditions—such as high speeds, dense media, and hard materials—will accelerate the wear of the grinding media. This worn material can contaminate your final product, which is a critical concern in applications like pharmaceuticals or high-purity ceramics.

Making the Right Choice for Your Goal

Your milling strategy should be dictated by your end goal. There is no single "best" setup; there is only the best setup for your specific objective.

- If your primary focus is breaking down coarse, hard material: Use larger, denser grinding media (like steel) to maximize impact force and fracture the initial particles.

- If your primary focus is producing very fine or nano-sized powders: Use smaller media to increase impact frequency and run at a lower feed rate to maximize particle residence time.

- If your primary focus is maximizing throughput for a bulk product: You will likely need to accept a coarser final grind, optimizing mill speed and feed rate for efficiency rather than absolute fineness.

By systematically adjusting these variables, you can move from merely operating a ball mill to precisely engineering your desired particle size.

Summary Table:

| Factor | Influence on Product Size | Key Consideration |

|---|---|---|

| Grinding Media Size | Larger media = coarser grind; Smaller media = finer grind | Determines impact force vs. frequency |

| Mill Rotational Speed | Speed below critical point maximizes cascading impacts | Avoids inefficient sliding or centrifuging |

| Material Feed Rate | Slower feed = longer residence time = finer particles | Balances product fineness with throughput |

| Media Density & Fill Level | Higher density = more energy; Optimal fill = efficient grinding | Affects impact energy and media movement |

Ready to achieve precise particle size control in your lab? The experts at KINTEK are here to help. We specialize in providing the right lab equipment, including ball mills and grinding media, tailored to your specific material and throughput needs. Whether you're developing pharmaceuticals, advanced ceramics, or other fine powders, we can help you optimize your process for maximum efficiency and product quality.

Contact our technical team today for a personalized consultation and let us help you engineer your perfect grind.

Visual Guide

Related Products

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Mini Planetary Ball Mill Machine for Laboratory Milling

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Powerful Plastic Crusher Machine

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

People Also Ask

- How do you clean ball milling media? A Step-by-Step Guide to Prevent Cross-Contamination

- What is the function of a planetary ball mill in the preparation of Na2Ni2TeO6? Optimize Your Precursor Synthesis

- What is the function of a high-energy ball mill in HEA mechanical alloying? Achieve Atomic-Level Solid-State Mixing

- What is the primary function of a ball mill during the wet mixing of LNMO? Achieve Microscopic Chemical Uniformity

- Purpose of Stainless Steel Grinding Balls in Ti-Fe Alloying: Optimize Impact & Filling Rates

- Why is the precise control of rotor tip speed critical? Master Dry Coating for High-Performance Battery Materials

- Why is a high-purity argon atmosphere necessary during the mechanical alloying of metal powders? Protect Ti and Al

- What is the function of a planetary ball mill in wet grinding BCZYYb? Master High-Energy Powder Homogenization