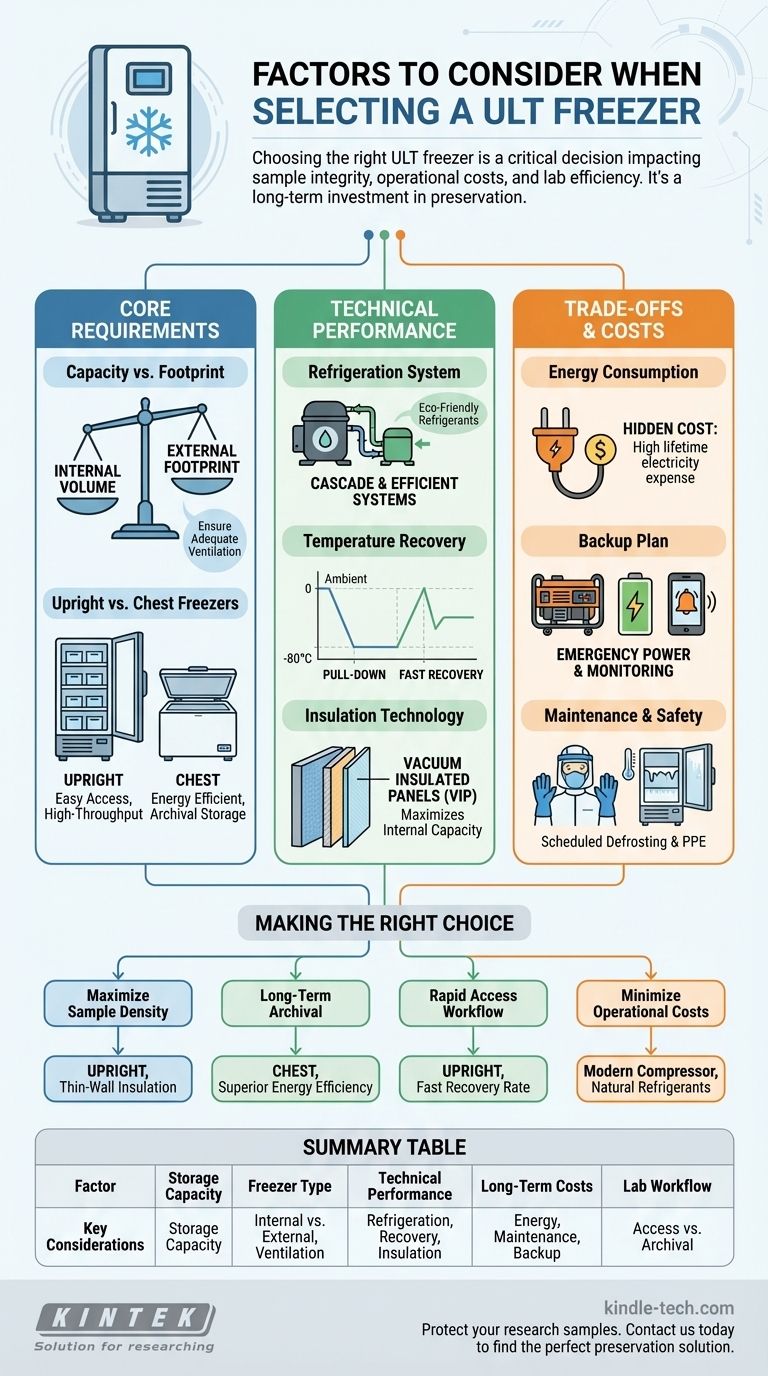

Choosing the right Ultra-Low Temperature (ULT) freezer is a critical decision that extends far beyond a simple equipment purchase. The key factors to consider are the freezer's storage capacity relative to its physical footprint, its energy efficiency, its technical performance under real-world conditions, and how it aligns with your lab's workflow and budget. This choice directly impacts the integrity of your samples, your operational costs, and your daily lab efficiency.

The goal is not merely to buy a freezer, but to invest in a long-term sample preservation system. The right choice balances your immediate storage needs with the ongoing realities of energy consumption, lab space, and workflow efficiency to protect your most valuable assets.

Evaluating Your Core Requirements

Before diving into technical specifications, you must first define your lab's specific needs. A clear understanding of your constraints and goals will guide your entire selection process.

Storage Capacity vs. Physical Footprint

The most fundamental balance is between how much you need to store and how much space you have. Measure the intended location carefully, including doorways and hallways the unit must pass through.

Proper placement is also critical for performance. The freezer requires adequate ventilation and airflow around it to operate efficiently and avoid overheating, which increases energy consumption.

Upright vs. Chest Freezers

This is one of the first major decisions you will make. Upright freezers offer excellent accessibility and organization, making it easy to retrieve samples quickly, which is ideal for high-throughput workflows.

Chest freezers, on the other hand, are generally more energy-efficient. Their top-opening design means less cold air escapes when opened, reducing the energy needed to restore the set temperature.

Analyzing Technical Performance

The internal mechanics of a ULT freezer determine its ability to protect your samples, especially during daily use or unexpected events.

The Refrigeration System

The heart of the freezer is its refrigeration system. Cascade systems use two separate refrigeration circuits, providing robust and often faster cooling. Other models may use a single, highly efficient compressor.

The type of refrigerants used, such as natural hydrocarbons, can also significantly impact energy efficiency and environmental friendliness.

Temperature Recovery and Uniformity

Pull-down time measures how long the freezer takes to reach its target temperature (−80°C) from ambient. Modern units typically take 3 to 5 hours.

More importantly for daily use is the warm-up time and recovery after a door opening. A freezer that can quickly return to its setpoint after being accessed provides better protection for all stored samples.

Insulation Technology

The type of insulation affects both the freezer's footprint and its energy use. Advanced vacuum insulated panels provide excellent thermal protection with thinner walls, maximizing internal storage capacity for a given external size.

Understanding the Trade-offs and Long-Term Costs

A ULT freezer is a 24/7 operational commitment. The initial purchase price is only one part of its total cost of ownership.

Energy Consumption: The Hidden Cost

ULT freezers are among the most energy-intensive pieces of equipment in a lab. A difference in energy efficiency that seems small on a spec sheet can translate into thousands of dollars in electricity costs over the unit's lifespan.

The Importance of a Backup Plan

Equipment failure or a power outage can be catastrophic. A comprehensive plan must include access to a backup power source, like an emergency generator, and robust temperature monitoring and alarm systems to alert staff to any deviations.

Maintenance and Safety Protocols

Proper operation is key to longevity and safety. This includes following scheduled defrosting procedures to maintain efficiency and using appropriate personal protective equipment (PPE), such as insulated gloves, to prevent cold burns.

Making the Right Choice for Your Lab

Your final decision should be a direct reflection of your lab's primary activities and constraints.

- If your primary focus is maximizing sample density: Prioritize an upright freezer with high-efficiency, thin-wall insulation to get the most storage in a small footprint.

- If your primary focus is long-term archival with minimal access: A chest freezer is an excellent choice for its superior energy efficiency and temperature stability.

- If your primary focus is rapid access in a high-throughput workflow: Select an upright freezer with documented fast temperature recovery rates after door openings.

- If your primary focus is minimizing operational costs: Closely compare the energy consumption ratings (kWh/day) and consider models with modern, energy-efficient compressors and natural refrigerants.

By carefully matching the freezer's characteristics to your research needs, you are making a strategic investment in the future success and integrity of your work.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Storage Capacity | Internal volume vs. external footprint; placement for proper ventilation. |

| Freezer Type | Upright (easy access) vs. Chest (energy-efficient). |

| Technical Performance | Refrigeration system, temperature recovery time, insulation type. |

| Long-Term Costs | Energy consumption (kWh/day), maintenance needs, backup power requirements. |

| Lab Workflow | High-throughput access vs. long-term archival storage. |

Protect your critical research samples with the right Ultra-Low Temperature freezer. The choice directly impacts sample integrity, operational costs, and lab efficiency. At KINTEK, we specialize in providing reliable lab equipment, including ULT freezers, tailored to meet the specific needs of your laboratory. Our experts can help you navigate the key factors—from capacity and energy efficiency to technical performance—ensuring you make a strategic investment. Contact us today via the form below to discuss your requirements and find the perfect preservation solution for your valuable work.

Visual Guide

Related Products

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

- 808L Precision Laboratory Vertical Ultra Low Temperature Freezer

People Also Ask

- What are ultra-low temperature freezers designed for? Preserving Your Most Valuable Biological Samples

- How are advancements in compressor technology and refrigerant fluids improving ULT freezers? Boost Efficiency & Cut Costs

- What temperature ranges are typically associated with ultra-low temperature freezers? Preserve Samples from -40°C to -86°C

- How is temperature controlled in ultra low temperature freezers? A Guide to Stable -80°C Storage

- What are the recommendations for storing mRNA vaccines in ultra-low temperature freezers? Ensure Absolute Stability at -80°C