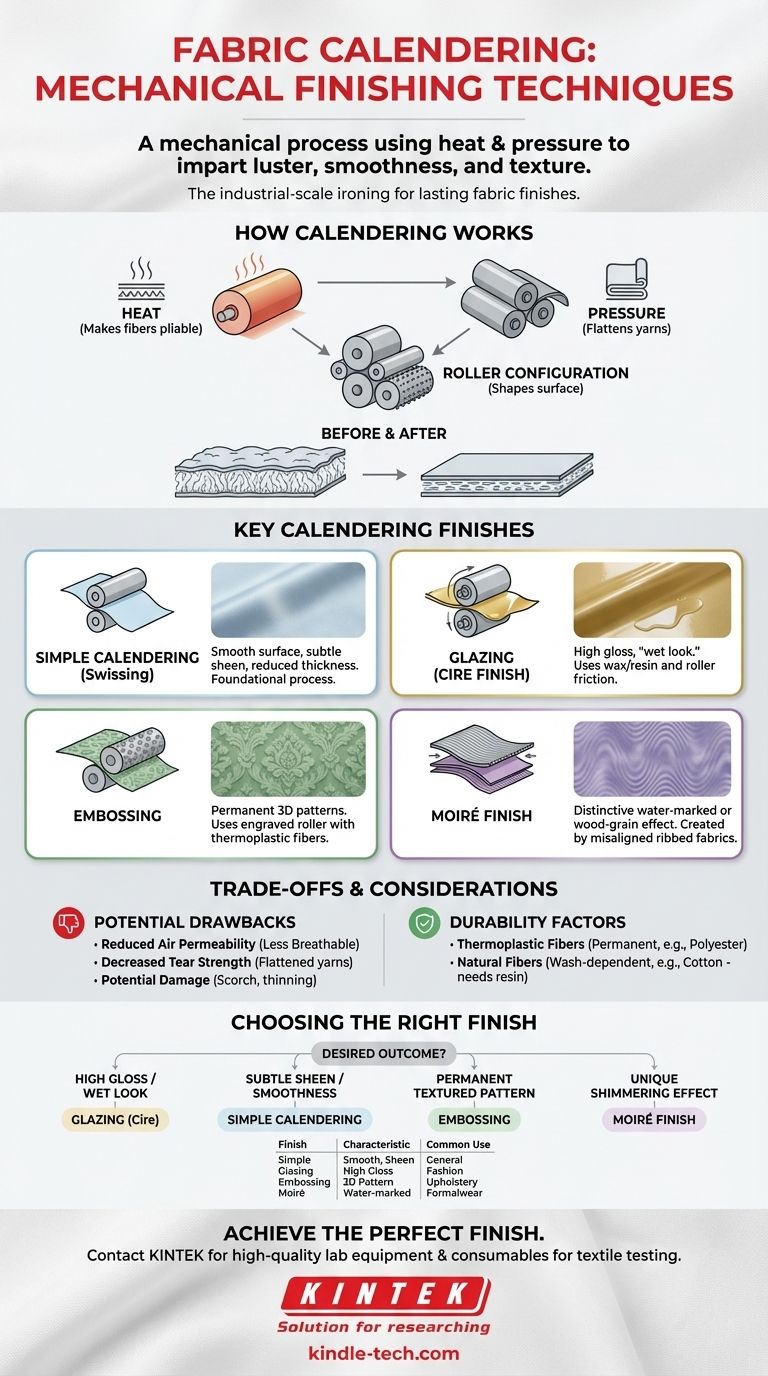

In short, calendering is a mechanical finishing process used to impart effects like high luster, smoothness, and specific surface textures onto fabric. It operates by passing the material between heated, high-pressure rollers, which fundamentally alters the fabric's surface and hand feel. This technique is most common for woven goods.

The core principle of calendering is using controlled heat and immense pressure to manipulate a fabric's surface. Think of it as a sophisticated, industrial-scale ironing process designed not just to remove wrinkles, but to create a range of specific, lasting finishes.

How Calendering Fundamentally Works

The effectiveness of calendering comes from the precise combination of three factors: pressure, heat, and roller configuration. These elements work together to modify the physical properties of the fabric's yarns.

The Role of Pressure

Heavy rollers apply immense pressure, flattening the yarns within the fabric structure. This action closes the gaps between threads, creating a more uniform and compact surface.

The Role of Heat

Heat makes thermoplastic fibers (like polyester) or resins applied to natural fibers (like cotton) more pliable. This softening allows the pressure to reshape the yarn cross-sections and lock in the desired finish as the fabric cools.

Key Finishes Achieved Through Calendering

Different roller configurations and process parameters produce distinct, named finishes. Each one targets a specific aesthetic or functional outcome.

Simple Calendering (Swissing)

This is the most basic form of calendering. The fabric is passed between two heated, smooth rollers to create a smooth surface, reduce thickness, and impart a subtle sheen. It's the foundational process for many other finishes.

Glazing (Cire Finish)

To achieve a very high gloss or "wet look," the fabric is first treated with a starch, wax, or resin. It is then passed through a specialized calender where one roller rotates significantly faster than the other. This speed difference creates friction, which polishes the surface to a brilliant shine.

Embossing

This process uses one engraved roller and one soft roller. The engraved roller presses a three-dimensional pattern into the fabric. When used with thermoplastic fibers, the heat and pressure create a permanent, wash-resistant design.

Moiré Finish

A moiré finish creates a distinctive "water-marked" or "wood-grain" pattern. This is often achieved by pressing two layers of a ribbed fabric (like taffeta) together, causing the rib patterns to slightly misalign and interfere with each other, which creates the unique visual effect.

Understanding the Trade-offs

While calendering offers significant aesthetic benefits, it's essential to understand its limitations and potential drawbacks.

Impact on Fabric Properties

The intense pressure can reduce a fabric's air permeability, making it less breathable. It can also decrease the fabric's tear strength, as the flattened yarns may be more susceptible to breaking under stress.

Durability of the Finish

The permanence of a calendered finish depends heavily on the fiber type. For thermoplastic fibers like polyester or nylon, finishes like embossing are permanent. On natural fibers like cotton, finishes may degrade over time with washing unless set with a resin.

Potential for Damage

Incorrect temperature or pressure settings can easily damage the fabric. Excessive heat can scorch or melt fibers, while improper pressure can lead to thinning or weakening of the material.

Making the Right Choice for Your Goal

Selecting the appropriate calendering finish depends entirely on the desired end-use and aesthetic for the fabric.

- If your primary focus is a high-gloss, wet look: A glazed or cire finish is the correct choice, especially on tightly woven synthetic fabrics.

- If your primary focus is adding a subtle, elegant sheen and smoothness: Simple calendering is the most direct and effective method.

- If your primary focus is creating a permanent, textured pattern: Embossing is the ideal technique, particularly for fabrics with thermoplastic fiber content.

- If your primary focus is a unique, shimmering visual effect: A moiré finish will produce the characteristic water-marked appearance you need.

Ultimately, calendering is a versatile tool that transforms a standard fabric into one with a specific character and enhanced value.

Summary Table:

| Finish Type | Key Characteristic | Common Use |

|---|---|---|

| Simple Calendering | Smooth surface, subtle sheen | General fabric finishing |

| Glazing (Cire) | High gloss, wet look | Fashion, outerwear |

| Embossing | 3D patterned surface | Upholstery, decorative textiles |

| Moiré | Water-marked, shimmering effect | Formalwear, drapery |

Ready to achieve the perfect fabric finish for your product? The right calendering technique can transform your material's look, feel, and value. At KINTEK, we specialize in providing high-quality lab equipment and consumables for textile testing and development. Whether you're working on fabric research or quality control, our solutions help you achieve precise, consistent results. Contact our experts today to discuss how we can support your laboratory's textile finishing needs!

Visual Guide

Related Products

- Double Plate Heating Press Mold for Lab

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

People Also Ask

- What is the hot press molding method? A Guide to Shaping Materials with Heat & Pressure

- What are the different types of press machines? Choose the Right Heating Tech for Your Application

- What is the temperature range for compression molding? Optimize Your Process for Perfect Parts

- How is conventional heating different from induction heating? Direct vs. Indirect Heat Explained

- Why is it necessary to use high-precision temperature-controlled heating furnaces? Secure Natural Fiber Integrity.