At its core, a calendering machine is an industrial assembly that uses a series of large, heavy rollers to finish or form a continuous sheet of material. By applying immense pressure—and often heat—these rollers can smooth, thin, emboss, or otherwise alter the physical properties of substances like textiles, plastics, rubber, and paper.

The central purpose of calendering is to achieve precise control over a material's final thickness, surface texture, and density. It is the industrial-scale process for transforming a raw sheet into a highly finished product.

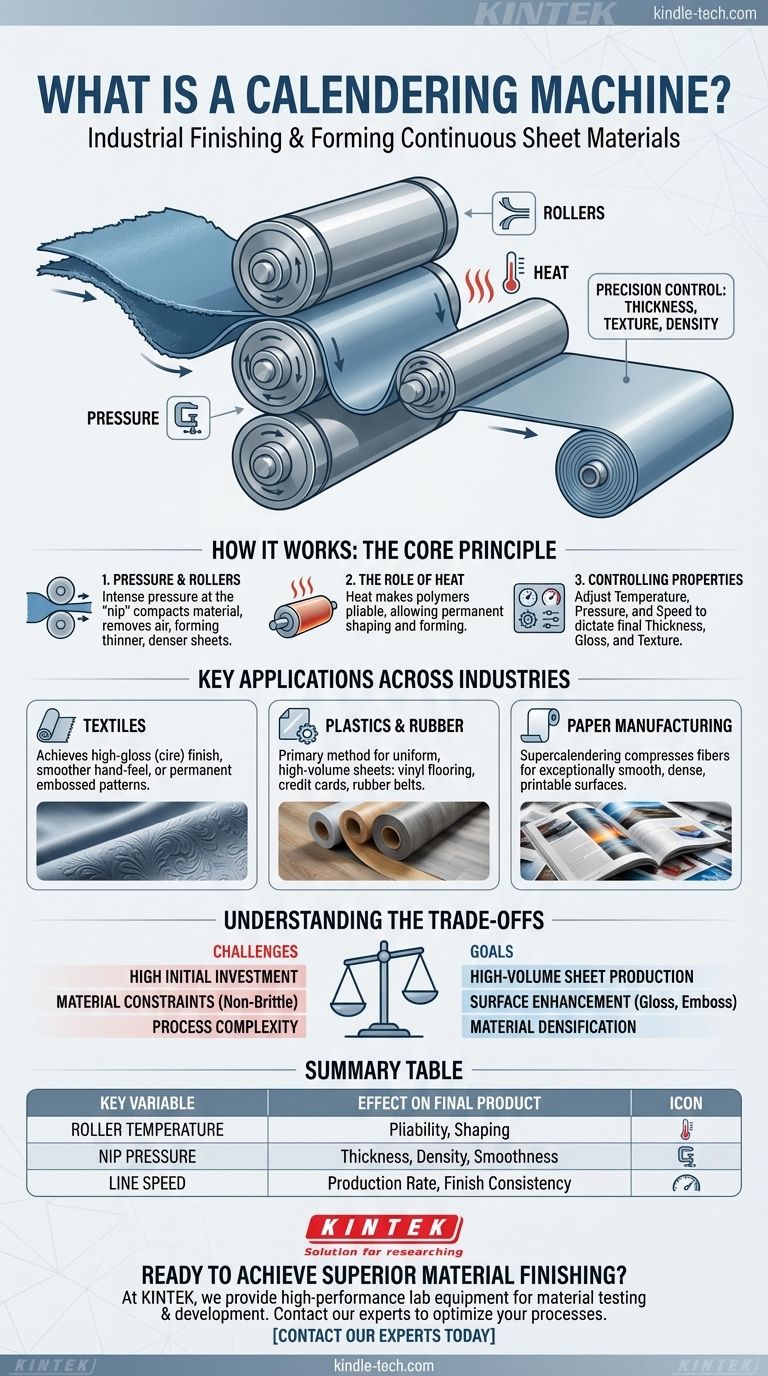

How a Calender Works: The Core Principle

A calender's function, while applied to many materials, relies on a consistent mechanical principle: passing a material through one or more "nips," which are the points of contact between two counter-rotating rollers.

The Role of Pressure and Rollers

A calender stack consists of multiple rollers made of hard materials like steel or specialized composites. As the material web passes through the nip between these rollers, it is subjected to extreme, controlled pressure.

This pressure compacts the material, squeezing out air and forcing it into a thinner, denser, and smoother sheet. The configuration and number of rollers determine the degree and type of finishing.

The Importance of Heat

For many applications, particularly with polymers like vinyl and rubber, the rollers are heated. Heat makes the material more plastic and pliable.

This allows the calendering process not just to smooth the material, but to fundamentally shape it, ensuring it holds its new form after cooling.

Controlling Material Properties

The final output is determined by precise control over several key variables: the temperature of the rollers, the pressure applied at the nips, and the speed at which the material travels through the machine.

By adjusting these parameters, operators can precisely dictate the final thickness, gloss level, and texture of the product.

Key Applications Across Industries

Calendering is a versatile finishing process used wherever a continuous sheet of material requires specific surface or dimensional properties.

For Textiles: Achieving the Final Finish

In textile manufacturing, calendering is a critical finishing step. It can be used to impart a high-gloss (cire) finish, create a smoother and softer hand-feel, or emboss a permanent pattern onto the fabric's surface.

For Plastics and Rubber: Creating Uniform Sheets

Calendering is the primary method for producing large quantities of flexible and rigid plastic sheeting. Products like vinyl flooring, pool liners, credit cards, and rubber conveyor belts are made by passing molten polymer through calender rolls to form a continuous sheet of a highly consistent thickness.

For Paper Manufacturing: Enhancing Smoothness and Gloss

After paper is formed, it often has a rough surface. A process called "supercalendering" uses a stack of hard and soft rollers to compress the paper fibers.

This creates an exceptionally smooth, dense surface that reduces ink bleed and is ideal for high-quality printing in magazines and catalogs.

Understanding the Trade-offs

While powerful, calendering is a specialized process with specific requirements and limitations.

High Initial Investment

Calendering machines are massive, complex, and expensive pieces of capital equipment. They represent a significant investment and are only justifiable for high-volume, continuous production environments.

Material Constraints

The process is best suited for materials that can be formed into a continuous web and can withstand high compressive forces. Brittle materials that would fracture under pressure are not suitable for calendering.

Process Complexity

Achieving a specific, consistent finish requires deep process knowledge. Fine-tuning the balance between roller temperature, pressure, and line speed is a complex task that demands significant operator skill and quality control.

Making the Right Choice for Your Goal

Calendering is not a universal solution, but it is the definitive process for specific manufacturing outcomes.

- If your primary focus is high-volume sheet production: Calendering is the industry standard for creating continuous sheets of plastic or rubber with precise thickness control.

- If your primary focus is surface enhancement: Use calendering to add gloss, smoothness, or embossed patterns to textiles, paper, or polymer films at high speed.

- If your primary focus is material densification: This process is essential for compressing materials like paper to improve their surface quality, strength, and printability.

Ultimately, understanding calendering is understanding a fundamental tool for manipulating the physical form and finish of materials on an industrial scale.

Summary Table:

| Key Variable | Effect on Final Product |

|---|---|

| Roller Temperature | Controls material pliability and shaping ability. |

| Nip Pressure | Determines final thickness, density, and smoothness. |

| Line Speed | Influences production rate and consistency of finish. |

Ready to achieve superior material finishing and precise thickness control?

At KINTEK, we specialize in providing high-performance lab equipment and consumables for material testing and development. Whether you are working with textiles, polymers, or paper, our expertise can help you optimize your processes.

Contact our experts today to discuss how our solutions can meet your specific laboratory needs and drive your projects forward.

Visual Guide

Related Products

- Small Lab Rubber Calendering Machine

- Powerful Plastic Crusher Machine

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

People Also Ask

- What is the principle of calendering? Enhance Fabric Surface with Heat and Pressure

- What is the process of calendering? A Guide to High-Volume Plastic Film Production

- What is the role of a laboratory crushing and sieving system in microalgae pyrolysis? Enhance Your Yield Efficiency

- What is the process of calendering in plastic processing? A Guide to High-Volume Film & Sheet Production

- What are the ingredients used in rubber compounding? A Guide to the Essential Formula