The most common and critical error in sieve analysis is improper sampling or sample preparation. Using a sample that isn't representative of the entire bulk material, or failing to properly dry the particles before testing, will introduce fundamental inaccuracies that render the final particle size distribution meaningless, regardless of how well the rest of the procedure is executed.

Sieve analysis is a process where the final result is only as strong as its weakest link. While many focus on the mechanical sieving step, the most significant errors are often introduced before the test even begins through poor sampling and inadequate sample conditioning.

Foundational Errors: Where Analysis Fails Before It Starts

The integrity of your entire analysis is determined by the quality of the material you test. Errors made at this initial stage cannot be corrected later in the process.

The Critical Role of Representative Sampling

A small sample is used to characterize a much larger batch of material. If this sample isn't a true representation of the whole, the analysis is fundamentally flawed.

For example, taking a sample just from the top of a container may result in a bias towards finer or coarser particles that have segregated during transport or storage. Proper sampling techniques, like using a sample splitter or quartering, are essential.

The Impact of Moisture and Agglomeration

Sieve analysis relies on individual particles falling through apertures. If the sample is damp, fine particles will agglomerate, or clump together.

These clumps will behave like larger particles, failing to pass through sieves they otherwise would. This skews the results, indicating a coarser particle distribution than is actually present. Proper drying is therefore not an optional step; it is mandatory for accuracy.

Errors During the Sieving Procedure

Once you have a good sample, procedural mistakes during the mechanical separation can still invalidate your results.

Sieve Overloading

Placing too much sample material onto the top sieve is a frequent mistake. This overloads the mesh surfaces, preventing particles from having a fair chance to pass through the openings.

This "blinding" effect causes a traffic jam on the sieve mesh, leading to an artificially high amount of material being retained on the upper sieves.

Incorrect Sieving Time or Intensity

The duration and energy of shaking are critical variables.

Too short a time will result in incomplete separation, leaving fine particles on upper sieves. Too long a time, especially with friable (brittle) materials, can cause particle attrition, where particles break down and generate more fines, skewing the distribution towards smaller sizes.

Damaged or Clogged Sieves

The accuracy of the analysis is directly tied to the precise aperture size of the sieve mesh. Dented frames, stretched wires, or torn mesh will produce incorrect results.

Likewise, failing to clean sieves properly after use can leave particles lodged in the mesh, effectively reducing the open area and preventing proper separation in the next test.

Understanding the Inherent Limitations

Beyond direct errors, you must be aware of the method's built-in limitations. Mistaking these for procedural flaws can lead to misinterpretation of the data.

Limited Size Resolution

A standard sieve stack typically uses a maximum of eight sieves. This means your entire particle size distribution curve is based on just a handful of data points, offering a low-resolution view of the distribution.

Lower Particle Size Limit

Sieve analysis becomes unreliable for particles smaller than approximately 50 micrometers (µm). At this scale, forces like static electricity and cohesion cause fine particles to stick to each other and the sieve mesh, preventing effective separation by gravity.

The Time Investment

A proper sieve analysis, including drying, weighing, sieving, and re-weighing, is a time-consuming manual process. This can be a significant practical limitation in high-throughput quality control environments.

Ensuring Accurate Sieve Analysis Results

To get trustworthy data, you must shift your focus from merely performing the steps to ensuring the integrity of each stage.

- If your primary focus is process control and consistency: Standardize your sampling technique and sieving time/intensity above all else to ensure your results are repeatable day-to-day.

- If your primary focus is material characterization for R&D: Pay rigorous attention to sample drying and inspect your sieves for damage before every run to ensure absolute accuracy.

- If you are comparing results with another lab or a supplier: Ensure both parties are using the exact same standard method (e.g., ASTM, ISO), including an identical sieve stack, sample mass, and sieving time.

By treating sieve analysis as a meticulous, multi-step process, you transform it from a simple mechanical task into a reliable analytical tool.

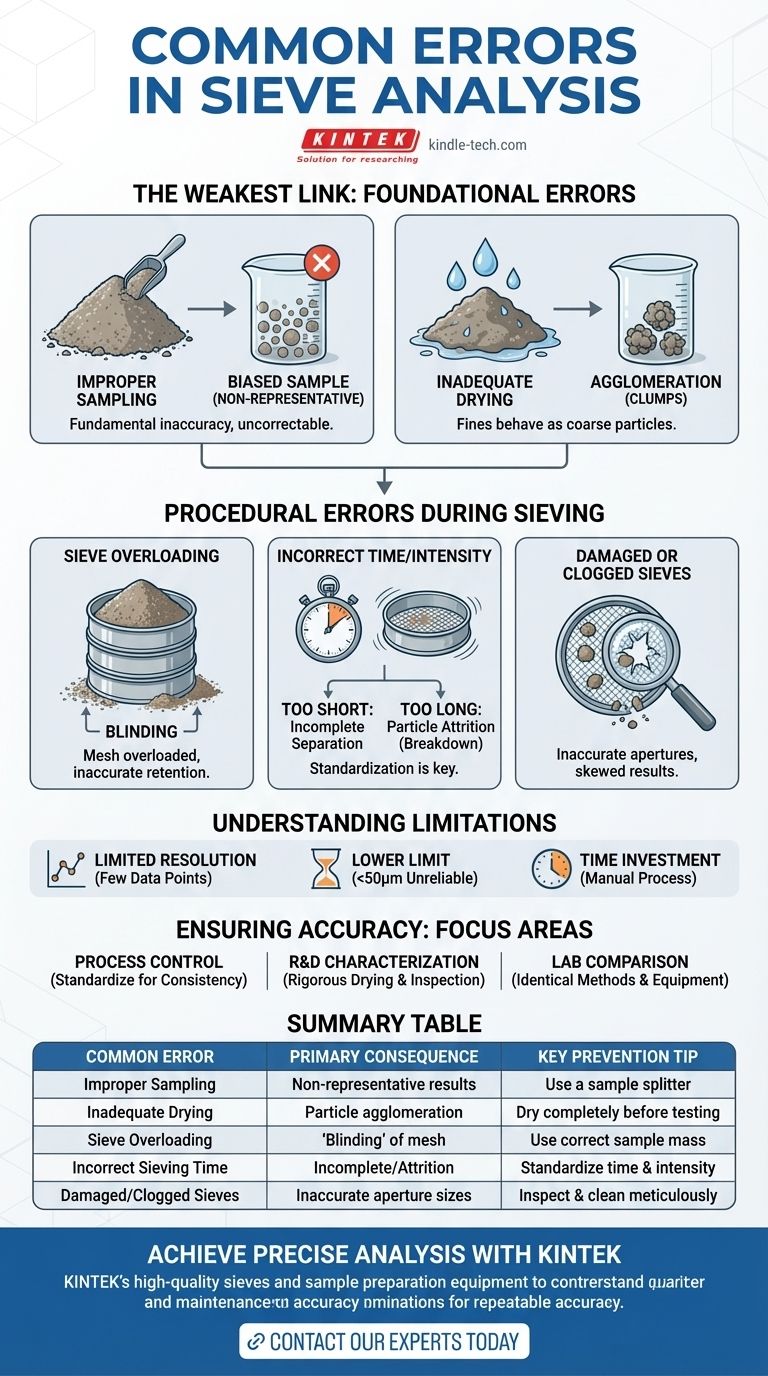

Summary Table:

| Common Error | Primary Consequence | Key Prevention Tip |

|---|---|---|

| Improper Sampling | Non-representative results | Use a sample splitter or quartering method |

| Inadequate Drying | Particle agglomeration, fines reported as coarse | Dry sample completely before testing |

| Sieve Overloading | 'Blinding' of mesh, incomplete separation | Use correct sample mass for sieve size |

| Incorrect Sieving Time | Incomplete separation or particle attrition | Standardize time and intensity per material |

| Damaged/Clogged Sieves | Inaccurate aperture sizes, skewed results | Inspect and clean sieves meticulously after each use |

Achieve precise and reliable particle size analysis with KINTEK.

Inconsistent sieve analysis results can lead to costly production errors and quality control issues. KINTEK specializes in high-quality laboratory sieves, sample preparation equipment, and consumables designed to eliminate the common errors highlighted in this article. Our products ensure your sampling is representative, your sieves are in perfect condition, and your entire process is standardized for repeatable accuracy.

Let us help you strengthen the weakest links in your analytical process. Contact our experts today to discuss your specific lab requirements and find the right equipment to guarantee the integrity of your sieve analysis data.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

People Also Ask

- What is dry sieving? A Guide to Efficient Particle Size Separation

- What is the best material for a sieve? Match the Material to Your Application for Accurate Results

- What is another example of sieving? From Kitchen Colanders to Industrial Screens

- What are advantages and disadvantages of sieving method? A Guide to Reliable & Cost-Effective Particle Sizing

- What is the application of sieving method in pharmacy? Ensure Drug Quality, Safety, and Efficacy

- What are the uses of sieves in laboratory? Ensure Material Quality and Consistency

- What can be separated by sieving? A Guide to Particle Size Separation for Various Materials

- What are the advantages of the sieve method? Achieve Fast, Reliable Particle Size Analysis