A continuous pyrolysis plant is an automated industrial system designed to thermally decompose waste materials, such as tires, in the absence of oxygen without interruption. It continuously feeds raw material and discharges finished products, allowing it to convert waste into valuable resources like fuel oil and carbon black on a non-stop, 24/7 basis.

The defining characteristic of a continuous pyrolysis plant is not just the chemical process, but the engineering that enables uninterrupted, automated operation. This fundamental design shift from traditional "batch" systems maximizes efficiency, throughput, and profitability for large-scale waste recycling.

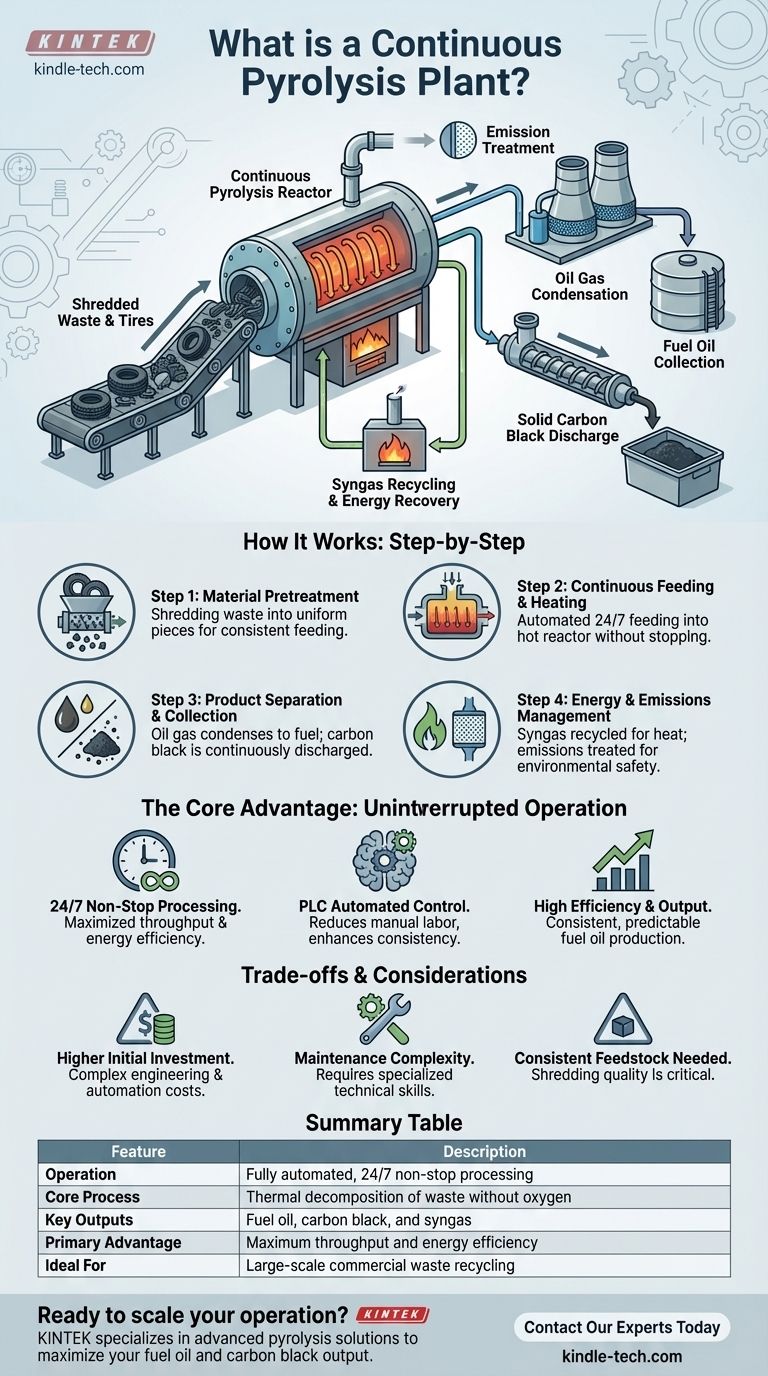

How Continuous Pyrolysis Works: A Step-by-Step Breakdown

The entire process is a highly integrated and automated workflow, managed by a central control system to ensure efficiency and safety from start to finish.

Step 1: Material Pretreatment

Before entering the core system, waste tires must be prepared. This involves using a wire drawing machine to remove the steel wires and then shredding the remaining rubber into small, uniform pieces.

Consistent feedstock size is critical for the stable operation of the continuous feeding mechanism.

Step 2: Continuous Feeding and Heating

The shredded tire pieces are fed into the pyrolysis reactor via a sealed, automated feeding system. This allows material to enter the hot reactor without requiring the system to shut down or cool off.

Once inside, the reactor is heated using a variety of potential fuels, including natural gas, coal, or even a portion of the combustible gas produced by the process itself.

Step 3: Product Separation and Collection

As the material heats up inside the reactor, it breaks down into oil gas and solid carbon black. This hot oil gas is channeled through a multi-stage cooling system.

The cooling process condenses the gas into liquid fuel oil, which is collected in storage tanks. The solid carbon black is simultaneously removed from the reactor using a sealed discharge system, like a screw conveyor.

Step 4: Energy and Emissions Management

The pyrolysis process also generates a non-condensable gas, often called syngas. This gas is captured, treated, and recycled back to the furnace to help heat the reactor, reducing external fuel consumption.

Any smoke generated from the initial fuel burning is treated through a separate purification system before being safely discharged, minimizing the plant's environmental impact.

The Core Advantage: What "Continuous" Truly Means

The term "continuous" signifies a fundamental advantage in operational design, moving beyond the limitations of older, batch-based systems.

Uninterrupted Operation

The plant does not need to be stopped, cooled, cleaned, and reloaded between each run. The continuous feeding and discharge systems allow it to operate around the clock, drastically increasing total processing capacity and saving significant energy that would be wasted on repeated heating and cooling cycles.

Automation and Control

These plants are typically managed by a Programmable Logic Controller (PLC) system. This central brain automates the entire workflow, from feeding rates to temperature control, reducing the need for manual labor and minimizing the chance of human error.

High Efficiency and Output

The combination of non-stop operation and optimized heating results in a higher and more consistent output of fuel oil. Many designs utilize multiple reactors or advanced internal rotating systems to ensure the raw material is heated evenly and completely, maximizing the conversion rate.

Understanding the Trade-offs and Considerations

While highly efficient, the continuous model presents its own set of challenges that must be considered for any practical application.

Higher Initial Investment

The sophisticated automated feeding/discharge systems, PLC controls, and robust engineering required for 24/7 operation make continuous plants significantly more expensive to build than simpler batch-style plants.

Maintenance Complexity

An integrated, non-stop system has more moving parts and complex control logic. Maintenance requires more specialized technical skill, and a failure in one component can potentially halt the entire production line.

Need for Consistent Feedstock

The automated feeding systems are designed for a specific size and quality of input material. This makes the pretreatment stage (shredding) absolutely critical; any variation in feedstock can disrupt the process and reduce efficiency.

Making the Right Choice for Your Goal

Selecting the right type of pyrolysis plant depends entirely on your operational scale and business objectives.

- If your primary focus is large-scale commercial processing: A continuous plant is the superior choice for its high throughput, lower labor costs per ton, and superior energy efficiency.

- If your primary focus is a smaller-scale operation or minimizing initial capital: A simpler batch plant may be a more accessible entry point, despite having higher operational costs and lower overall output.

- If your primary focus is product consistency and operational stability: The automation and precise process control of a PLC-managed continuous plant deliver unmatched reliability and predictable output.

Ultimately, choosing a continuous pyrolysis plant is an investment in industrial-scale efficiency and automation for waste-to-energy conversion.

Summary Table:

| Feature | Description |

|---|---|

| Operation | Fully automated, 24/7 non-stop processing |

| Core Process | Thermal decomposition of waste (e.g., tires) without oxygen |

| Key Outputs | Fuel oil, carbon black, and syngas |

| Primary Advantage | Maximum throughput and energy efficiency for large-scale operations |

| Ideal For | Large-scale commercial waste recycling and energy recovery projects |

Ready to scale your waste recycling operation with industrial-grade efficiency?

KINTEK specializes in advanced laboratory and processing equipment, including pyrolysis solutions. Our expertise can help you select the right system to maximize your output of fuel oil and carbon black.

Contact our experts today to discuss how a continuous pyrolysis plant can transform your waste stream into a profitable resource.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What are the different types of pyrolysis machines? Choose the Right System for Your Output