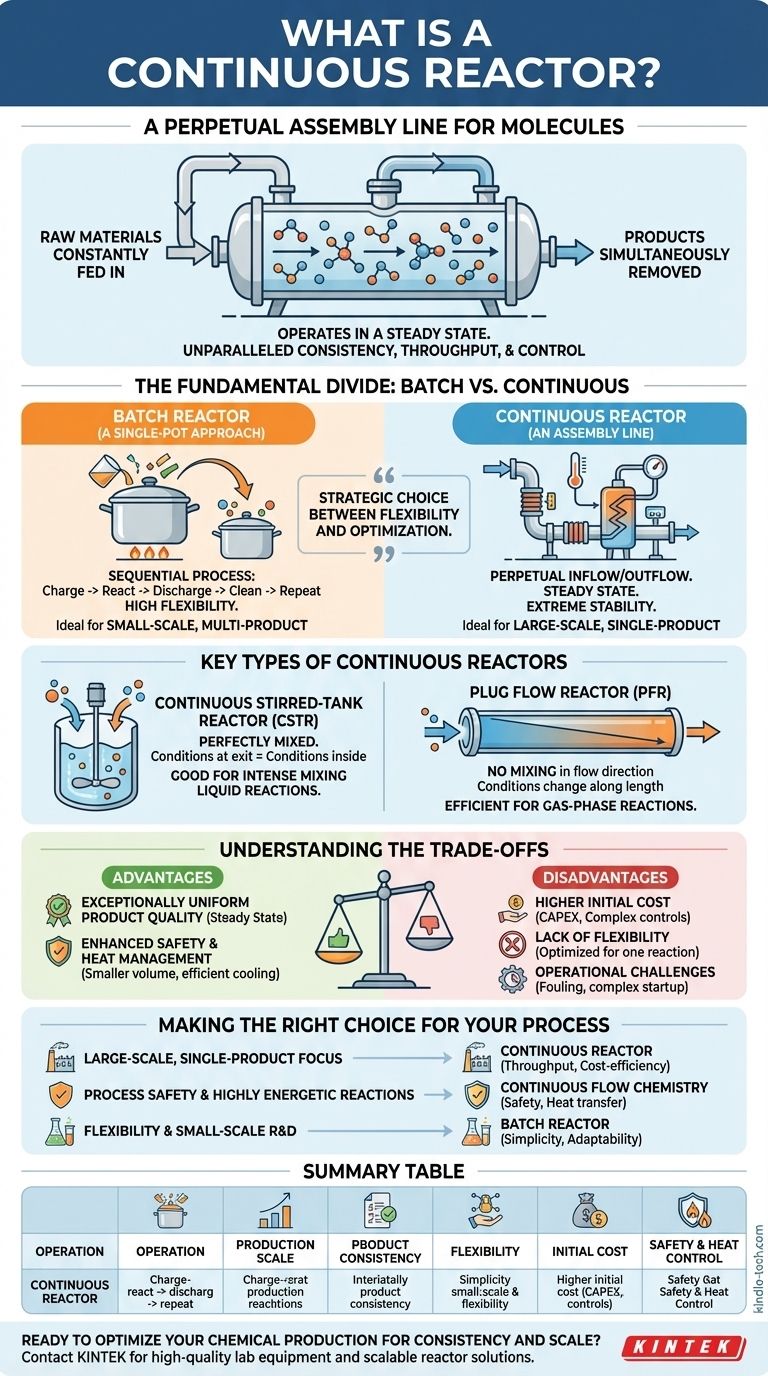

At its core, a continuous reactor is a vessel or system designed for chemical processes where raw materials are constantly fed in and products are simultaneously removed. Unlike a batch process where you mix ingredients, wait, and then empty the final product, a continuous reactor operates in a perpetual, steady state. It functions less like a cooking pot and more like an industrial assembly line for molecules.

The fundamental difference between batch and continuous processing is not just a matter of equipment, but a strategic choice between flexibility and optimization. Continuous reactors trade the adaptability of batch systems for unparalleled consistency, throughput, and control at scale.

The Fundamental Divide: Continuous vs. Batch Processing

To understand the value of a continuous reactor, you must first understand its counterpart. Chemical production is dominated by two primary philosophies: batch and continuous.

The Batch Reactor: A Single-Pot Approach

A batch reactor is the most intuitive type. It's like baking a cake: you add all your ingredients to a single vessel, let the reaction proceed for a set amount of time under specific conditions (e.g., heating, stirring), and then remove the entire final product.

The process is sequential: charge, react, discharge, clean, and repeat. This method is highly flexible and excellent for small-scale production or facilities that need to manufacture multiple different products.

The Continuous Reactor: An Assembly Line

A continuous reactor abandons this sequential approach. Reactants are perpetually pumped into the reactor while the product stream is perpetually drawn off.

After an initial startup period, the reactor reaches a steady state, where conditions inside (temperature, pressure, concentration) remain constant over time. This creates an extremely stable and predictable production environment.

Key Types of Continuous Reactors

While many specialized designs exist, most continuous reactors are based on two ideal models. Understanding them is key to grasping the core principles.

The Continuous Stirred-Tank Reactor (CSTR)

A CSTR is essentially a tank with a constant inflow of reactants and a constant outflow of product. An impeller or agitator ensures the contents are perfectly mixed.

Because of this perfect mixing, the concentration and temperature of the material exiting the reactor are assumed to be the same as the conditions everywhere inside the reactor. CSTRs are workhorses for liquid-phase reactions where intense mixing is beneficial.

The Plug Flow Reactor (PFR)

A PFR (also called a Tubular Reactor) is typically a long pipe or tube. Reactants enter one end, and the product emerges from the other. The key assumption is that there is no mixing in the direction of flow—fluid particles enter and exit in the same sequence, like a perfect, orderly queue.

In a PFR, reaction conditions change along the length of the reactor. The concentration of reactants is highest at the inlet and decreases as the fluid moves toward the outlet. This makes them highly efficient for many types of reactions, especially in the gas phase.

The Reality: Hybrid and Real-World Systems

Ideal CSTRs and PFRs are theoretical models. Real-world reactors often exhibit behavior somewhere between these two extremes. For instance, a series of CSTRs connected together can be used to approximate the performance of a single, larger PFR.

Understanding the Trade-offs

Choosing a continuous reactor is a decision with significant operational and economic consequences. It is not inherently "better," but rather better suited for specific goals.

Advantage: Consistency and Quality Control

Because a continuous reactor operates at a steady state, the product quality is exceptionally uniform. Once dialed in, the process can run for days, weeks, or months, producing the exact same product with minimal variation. This is a massive advantage for high-spec industries like pharmaceuticals and polymers.

Advantage: Enhanced Safety and Heat Management

Continuous reactors often have a much smaller volume than a batch reactor producing the same daily output. This means that at any given moment, the amount of hazardous or high-energy material is significantly smaller, reducing the risk of a thermal runaway. Their typically higher surface-area-to-volume ratio also allows for far more efficient heating and cooling.

Disadvantage: Higher Initial Cost (CAPEX)

Continuous systems are more complex. They require sophisticated process control systems, sensors, and pumps to maintain a steady state. This results in a significantly higher upfront capital investment compared to a simple batch setup.

Disadvantage: Lack of Flexibility

A continuous process is typically optimized for a single, specific reaction. It is very difficult and costly to reconfigure a continuous plant to produce a different product. Batch reactors, in contrast, can be easily cleaned and used for a completely different process the next day.

Disadvantage: Operational Challenges

Continuous reactors can be susceptible to issues like fouling, catalyst deactivation, or blockages, which can shut down the entire production line. Startup and shutdown procedures are also far more complex than simply filling or emptying a batch tank.

Making the Right Choice for Your Process

The decision to use a continuous reactor depends entirely on your operational and business priorities.

- If your primary focus is large-scale, single-product manufacturing: A continuous reactor is the superior choice, offering unmatched throughput, cost-efficiency per unit, and product consistency.

- If your primary focus is process safety with highly energetic reactions: The smaller volumes and superior heat transfer of continuous "flow chemistry" provide a significant safety advantage over large batch processing.

- If your primary focus is flexibility for multiple products or small-scale R&D: A batch reactor's simplicity, low initial cost, and adaptability are almost always the better choice.

Ultimately, understanding this fundamental choice empowers you to design a process that is not only chemically sound but also economically viable.

Summary Table:

| Feature | Batch Reactor | Continuous Reactor |

|---|---|---|

| Operation | Sequential (charge, react, discharge) | Perpetual inflow/outflow (steady state) |

| Production Scale | Ideal for small-scale, multi-product | Optimized for large-scale, single-product |

| Product Consistency | Can vary between batches | Extremely high and uniform |

| Flexibility | High (easy to change products) | Low (dedicated to one process) |

| Initial Cost (CAPEX) | Lower | Higher |

| Safety & Heat Control | Larger volume, higher risk | Smaller volume, superior heat transfer |

Ready to optimize your chemical production for consistency and scale?

Choosing the right reactor is critical to the efficiency, safety, and profitability of your process. The experts at KINTEK specialize in providing high-quality lab equipment and scalable solutions for chemical processing. Whether you are scaling up from R&D or optimizing an existing production line, we can help you select the perfect system for your needs.

Contact KINTEK today to discuss how our reactor solutions can bring unparalleled consistency and throughput to your laboratory or production facility.

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What is the primary role of high-pressure reactors in the hot water extraction (HWE) process? Unlock Green Biorefining

- What are the material requirements for reaction vessels using sodium hydroxide? Simplified Lab Equipment Solutions

- What is the function of high-pressure reactors in CFRP recycling? Unlocking Efficient Carbon Fiber Recovery

- What are the disadvantages of fluidized bed reactors? Key Challenges and Operational Drawbacks

- Why is a precise temperature control reaction system necessary for biomass pretreatment? Ensure High Yield & Low Toxicity

- What is the critical role of an autoclave in the solvothermal synthesis of MOFs? Unlock High-Crystallinity Structures

- Why are 5 to 10 mL microreactors preferred for hydrothermal synthesis? Master Particle Precision and Scalability

- Why are high nickel alloys or austenitic stainless steels required for methane pyrolysis? Ensuring Reactor Integrity