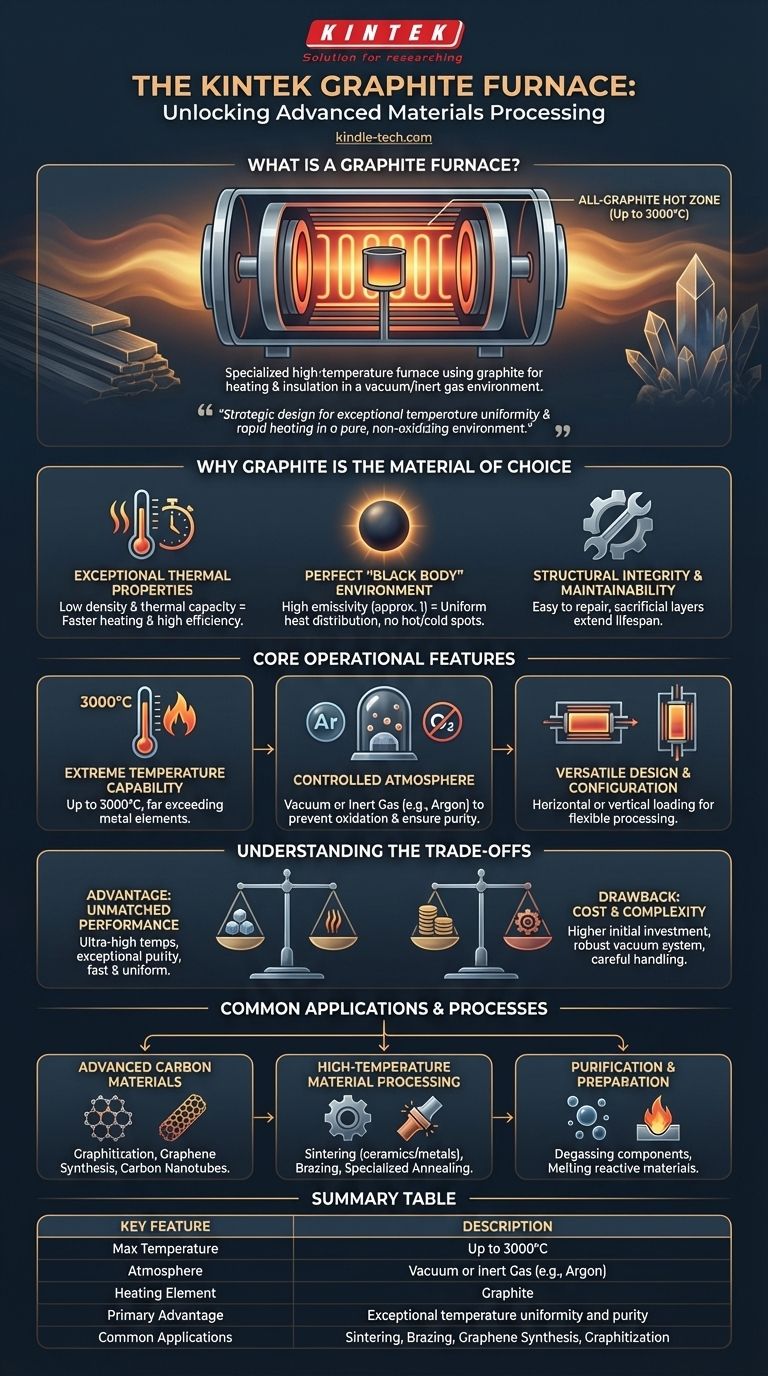

In essence, a graphite furnace is a specialized high-temperature furnace that utilizes graphite for its primary internal components, including the heating elements and the insulating chamber. This all-graphite "hot zone" allows the furnace to reach extreme temperatures, often up to 3000°C, within a highly controlled vacuum or inert gas atmosphere. This unique design makes it indispensable for advanced materials processing and scientific research.

The decision to use graphite is not merely a material choice; it is a strategic design principle. It enables exceptional temperature uniformity and rapid heating in a pure, non-oxidizing environment that is simply unattainable with conventional metal-element furnaces.

Why Graphite is the Material of Choice

The performance of a graphite furnace stems directly from the unique properties of graphite itself. It is chosen for its superior behavior at extreme temperatures.

Exceptional Thermal Properties

Graphite has a low density and modest thermal capacity. This means it requires less energy to heat up and can achieve its target temperature very quickly. This translates to faster processing cycles and higher operational efficiency compared to furnaces using denser, metallic components.

Creating a Perfect "Black Body" Environment

Graphite has an emissivity of nearly 1, making it an almost perfect "black body." In simple terms, it radiates thermal energy with exceptional uniformity. This ensures that the heat inside the furnace is distributed evenly, eliminating hot and cold spots and delivering highly consistent results across the entire workpiece.

Structural Integrity and Maintainability

Despite its high-temperature function, a graphite hot zone is relatively easy to repair. Furthermore, the chamber can be lined with sacrificial layers of graphite, which can be replaced periodically to protect the core structure and extend the furnace's operational lifespan.

Core Operational Features

A graphite furnace is not just a box that gets hot; it is a precisely controlled system designed for specific, demanding tasks.

Extreme Temperature Capability

The standout feature is its ability to operate at temperatures up to 3000°C. This pushes well beyond the limits of furnaces that rely on metallic heating elements, which would melt or degrade at such temperatures.

Controlled Atmosphere (Vacuum & Inert Gas)

These furnaces operate under a vacuum or are backfilled with an inert gas like argon. This is critical because it removes oxygen, which would cause the graphite components and the material being processed to rapidly oxidize and burn away at high temperatures. The result is a smoke-free, ultra-pure environment.

Versatile Design and Configuration

Most graphite furnaces feature a cylindrical, double-walled stainless steel vacuum chamber. They are often designed to be loaded and operated in either a horizontal or vertical orientation, providing flexibility to accommodate different processes and part geometries.

Understanding the Trade-offs

While powerful, graphite furnaces are a specialized tool. Understanding their limitations is key to making a sound investment decision.

The Advantage: Unmatched Performance

For processes requiring ultra-high temperatures, exceptional purity, and fast, uniform heating, the graphite furnace is in a class of its own. It enables the creation and processing of materials that are impossible to handle in other furnace types.

The Drawback: Cost and Complexity

This performance comes at a cost. Graphite furnaces have a higher initial investment than conventional furnaces. They also require a robust vacuum system and careful handling of large, vacuum-tight seals, which adds to their operational complexity and maintenance requirements.

Common Applications and Processes

The unique capabilities of graphite furnaces make them essential for a range of high-value industrial and research applications.

Advanced Carbon Materials

These furnaces are central to producing next-generation materials. Key applications include the graphitization of carbon, the synthesis of graphene, and the preparation of carbon nanotubes.

High-Temperature Material Processing

Many industrial processes rely on the precise thermal control of a graphite furnace. These include the sintering of ceramics and powdered metals, high-temperature brazing, specialized annealing, and firing advanced ceramics.

Purification and Preparation

The clean, vacuum environment is ideal for degassing components to remove trapped impurities and for melting highly reactive materials that cannot be exposed to air.

Making the Right Choice for Your Goal

Deciding if a graphite furnace is appropriate depends entirely on your process requirements.

- If your primary focus is creating advanced carbon materials like graphene: A graphite furnace is not just an option but a foundational tool, as it provides the necessary temperature and purity.

- If your primary focus is high-temperature sintering or brazing of critical components: A graphite furnace offers superior uniformity and speed, justifying the investment for high-value, performance-sensitive parts.

- If your primary focus is general heat treating below 1500°C in an air atmosphere: A conventional furnace with metallic elements is a far more practical and cost-effective solution.

Ultimately, selecting a graphite furnace is an investment in unparalleled thermal control and environmental purity for the most demanding material science applications.

Summary Table:

| Key Feature | Description |

|---|---|

| Max Temperature | Up to 3000°C |

| Atmosphere | Vacuum or Inert Gas (e.g., Argon) |

| Heating Element | Graphite |

| Primary Advantage | Exceptional temperature uniformity and purity |

| Common Applications | Sintering, Brazing, Graphene Synthesis, Graphitization |

Ready to push the boundaries of your materials research or production?

A graphite furnace from KINTEK provides the extreme temperatures, uniform heating, and ultra-pure environment required for sintering advanced ceramics, synthesizing graphene, brazing critical components, and other high-value processes. Our expertise in lab equipment ensures you get a system tailored to your specific goals, maximizing efficiency and ROI.

Contact our experts today to discuss how a KINTEK graphite furnace can accelerate your innovation.

Visual Guide

Related Products

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- Why is graphite used in furnaces? For Extreme Heat, Purity, and Efficiency

- Why graphite is used in furnace? Achieve Superior Heat Treatment & Energy Efficiency

- What are the advantages of graphite furnace? Achieve High-Temperature Precision and Purity

- What are the applications of graphite material? Leveraging Extreme Heat and Precision for Industrial Processes

- What is the temperature of a graphite furnace? Achieve Extreme Heat Up to 3000°C