In pharmaceuticals, a hammer mill is a crucial piece of equipment used for particle size reduction, also known as comminution. Its primary function is to break down large solid particles of Active Pharmaceutical Ingredients (APIs) or excipients into smaller, more uniform pieces. This process is fundamental for improving drug efficacy, manufacturability, and final product quality.

The core purpose of using a hammer mill is not just to make particles smaller, but to precisely control their size distribution. This control directly impacts how a drug dissolves in the body, how uniformly it can be mixed into a tablet, and how efficiently it can be processed during manufacturing.

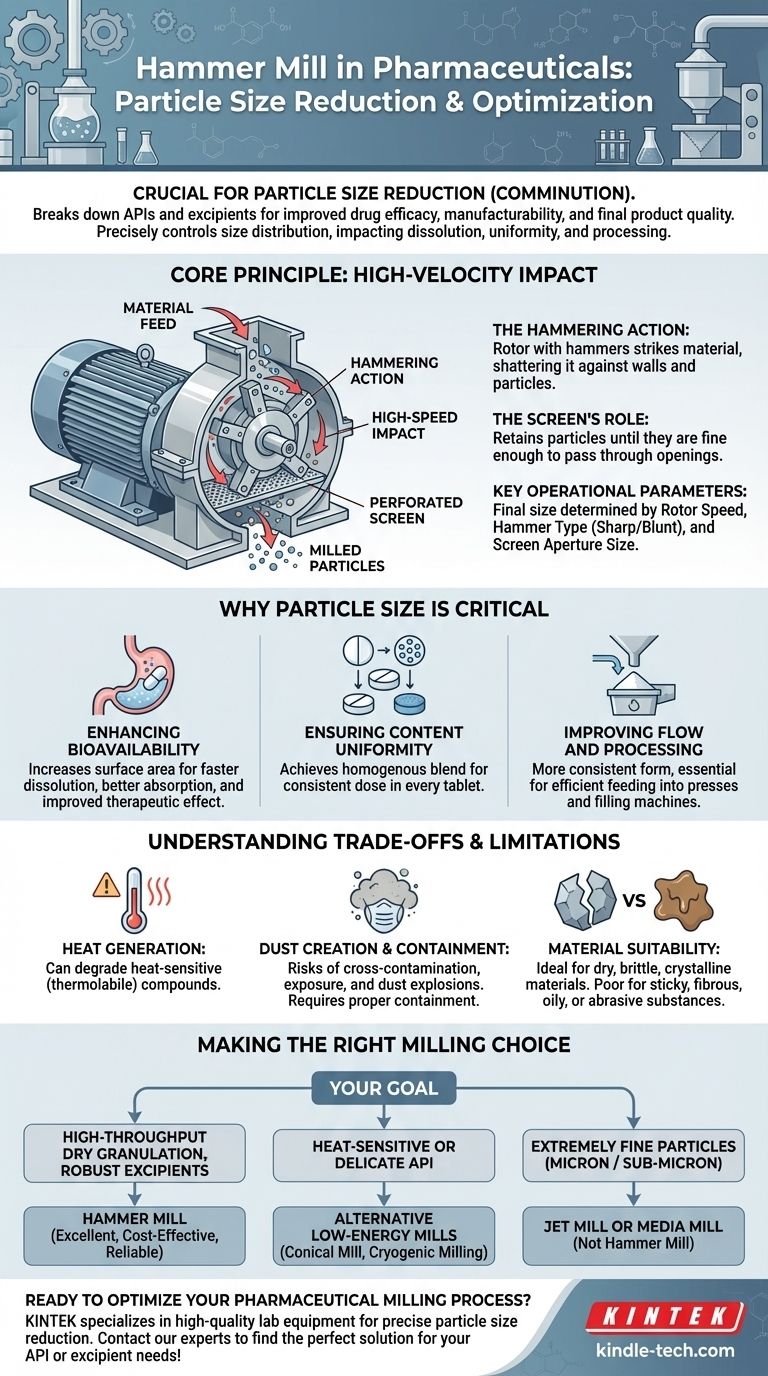

The Core Principle: How a Hammer Mill Works

A hammer mill operates on the principle of high-velocity impact. It is a mechanically simple yet effective device for pulverizing a wide range of dry, crystalline, or granular materials.

The Hammering Action

Material is fed into a chamber where a central rotor spins at high speed. This rotor is fitted with numerous swinging or fixed hammers. As the material enters, these hammers strike it with immense force, shattering it against the chamber's inner walls and other particles.

The Screen's Role

The bottom of the milling chamber is enclosed by a perforated screen or mesh. Milled particles remain in the chamber, continuously struck by the hammers, until they are fine enough to pass through the openings in this screen.

Key Operational Parameters

The final particle size is determined by three main factors: rotor speed, hammer type (sharp vs. blunt edge), and the screen's aperture size. A faster speed, sharper hammer edge, and smaller screen opening will all result in a finer powder.

Why Particle Size is Critical in Pharmaceuticals

Controlling particle size is a non-negotiable aspect of drug development and manufacturing. The hammer mill is a key tool for achieving this control, which has several critical downstream effects.

Enhancing Bioavailability

For poorly soluble drugs, reducing the particle size dramatically increases the surface area available for dissolution. A larger surface area allows the drug to dissolve faster in the body, leading to better absorption and improved therapeutic effect, or bioavailability.

Ensuring Content Uniformity

Imagine trying to mix a small amount of fine API powder with a large volume of coarse excipient granules. The mixture will likely be non-uniform. By milling all components to a similar particle size range, manufacturers can achieve a homogenous blend, ensuring that every tablet contains the exact same dose.

Improving Flow and Processing

Milling can break down irregularly shaped particles and aggregates into a more consistent form. This improves the powder's flowability, which is essential for efficient and consistent feeding into tablet presses and capsule-filling machines.

Understanding the Trade-offs and Limitations

While versatile, the hammer mill is not a universal solution. An objective assessment requires understanding its potential downsides.

Heat Generation

The high-speed impact generates significant heat. This can be problematic for thermolabile (heat-sensitive) compounds, potentially causing degradation of the API or unwanted physical changes in the material.

Dust Creation and Containment

The aggressive milling action can create a large amount of fine dust. In a pharmaceutical setting, this poses risks of cross-contamination, operator exposure, and even dust explosions with certain materials. Proper containment and dust collection systems are mandatory.

Material Suitability

Hammer mills are ideal for dry, brittle, or crystalline materials. They perform poorly with sticky, fibrous, oily, or highly abrasive substances, which can clog the screen or rapidly wear down the hammers.

Making the Right Milling Choice for Your Goal

Selecting the correct milling technology depends entirely on your material's properties and your final product requirements.

- If your primary focus is high-throughput dry granulation or milling of robust excipients: The hammer mill is an excellent, cost-effective, and reliable choice.

- If your primary focus is milling a heat-sensitive or delicate API: You should consider alternative low-energy mills, such as a conical mill, or cryogenic milling where the material is cooled with liquid nitrogen.

- If your primary focus is achieving extremely fine particles (micron or sub-micron range): A hammer mill is not the right tool; you would need to use a jet mill or a media mill.

Ultimately, choosing the right particle reduction technology is a critical decision that directly influences the safety, quality, and efficacy of the final pharmaceutical product.

Summary Table:

| Key Function | Benefit in Pharmaceuticals |

|---|---|

| Particle Size Reduction | Improves drug dissolution and bioavailability. |

| High-Impact Milling | Breaks down dry, crystalline materials efficiently. |

| Screen-Based Control | Allows for precise control over final particle size distribution. |

| High-Throughput Processing | Enables fast and reliable milling of APIs and excipients. |

Ready to optimize your pharmaceutical milling process? KINTEK specializes in high-quality lab equipment, including hammer mills designed for precise particle size reduction. Our expertise ensures you achieve the uniformity and efficiency critical for drug development and manufacturing. Contact our experts today to find the perfect milling solution for your API or excipient needs!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Powerful Plastic Crusher Machine

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- Mini Planetary Ball Mill Machine for Laboratory Milling

People Also Ask

- Why is a laboratory electromagnetic vibratory sieve shaker used? Optimize Walnut Shell Chemical Pretreatment

- Why is a standardized sieving system necessary for elephant grass research? Ensure Reliable Sample Consistency

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis

- How do high-precision sieving systems benefit zeolite preparation? Maximize Adsorption for Wastewater Treatment

- What function does a sieving system perform during HPS powder pretreatment? Ensure Uniform Particle Size Distribution