At its core, a pellet press is a machine that transforms loose, often low-density material into compact, solid pellets through intense compression. It achieves this by forcing the raw material through a die, creating a uniform product that is easier to handle, transport, and use. The term encompasses two vastly different scales of application: large-scale industrial production and small-scale, high-precision laboratory work.

A pellet press is not a single device but a category of machines unified by a core principle: densification through compression. Understanding whether the goal is industrial output (like fuel) or analytical precision (like scientific samples) is the key to understanding the specific machine in question.

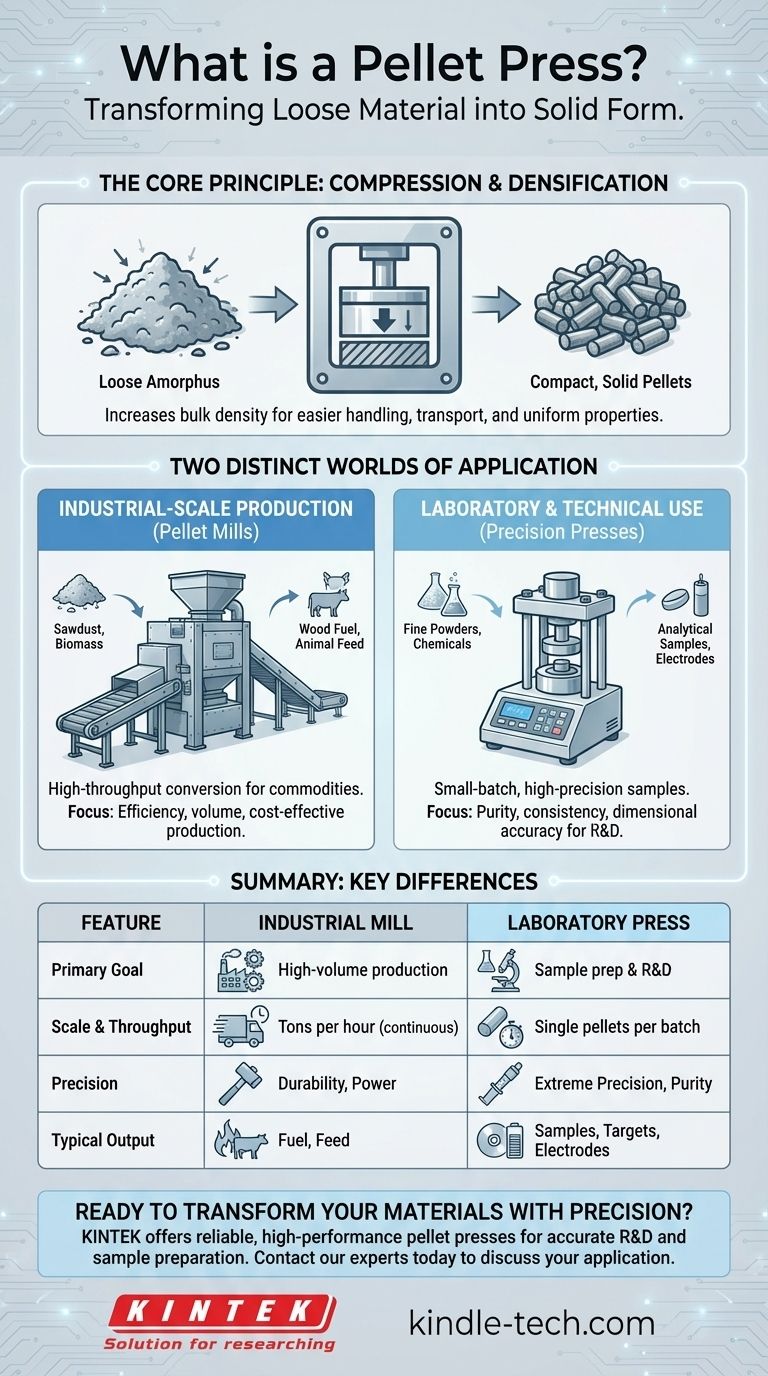

The Core Principle: Compression and Densification

A pellet press, regardless of its size or purpose, operates on a straightforward mechanical principle. Its primary function is to solve the problem of handling unwieldy, loose materials.

How It Works

The fundamental process involves feeding raw material into a chamber where it is forced through a specialized mold, known as a die, under immense pressure. This action compacts the material, binds it together, and extrudes it in the form of dense, uniform pellets.

The Purpose of Pelleting

The primary goal is to increase bulk density. By compacting loose matter like sawdust or powders, you dramatically reduce its volume. This makes the material significantly easier to store and transport, and it creates a standardized product with predictable properties for its final application.

Two Distinct Worlds of Pellet Presses

The term "pellet press" can be confusing because it refers to equipment in two completely separate fields. The scale, precision, and end-goal of these machines are entirely different.

Application 1: Industrial-Scale Production

In an industrial context, these machines are often called pellet mills. They are designed for high-throughput conversion of waste or raw biomass into valuable commodities.

Common inputs include sawdust, cardboard, agricultural waste, and other organic materials. The outputs are products like wood pellet fuel for heating or animal feed pellets for livestock and poultry. The focus here is on efficiency, volume, and cost-effective production.

Application 2: Laboratory and Technical Use

In scientific and technical settings, a pellet press is a much smaller, precision instrument. It is used to compress fine powders into small, solid discs or pellets for analysis or specialized manufacturing.

These pellets are used for applications like preparing geological samples for testing, forming battery electrodes, creating sputtering targets for electronics, or even manufacturing components for rocket nozzles. The focus is on purity, consistency, and creating a perfect sample.

Understanding the Key Differences

While they share a name, the contrast between an industrial pellet mill and a laboratory pellet press is stark. Choosing the wrong frame of reference can lead to significant misunderstanding.

Scale and Throughput

An industrial pellet mill is a large, continuous-process machine that can produce tons of material per hour. A laboratory press is a small, batch-process device that creates a single, small pellet at a time, often taking several minutes per sample.

Precision vs. Volume

A laboratory press is engineered for extreme precision. It applies a carefully controlled amount of pressure to create a pellet with a perfectly smooth surface and uniform density, which is critical for accurate scientific analysis. An industrial mill is built for raw power and durability to process massive volumes of material reliably.

The Nature of the Die

In an industrial mill, the die is a thick steel plate with many holes, and rollers force material through it continuously. In a laboratory press, the die is a small, precise mold used to form a single pellet or puck to exact dimensional specifications.

Making the Right Choice for Your Goal

Understanding your ultimate objective is the only way to determine which type of pellet press is relevant to your work.

- If your primary focus is waste conversion for fuel or feed: You are seeking an industrial pellet mill designed for high-volume biomass processing.

- If your primary focus is sample preparation for scientific analysis or R&D: You need a laboratory pellet press designed for creating small, high-purity, and dimensionally accurate solid samples from powders.

Ultimately, a pellet press is a powerful tool for transforming loose matter into a dense, practical, and highly usable form.

Summary Table:

| Feature | Industrial Pellet Mill | Laboratory Pellet Press |

|---|---|---|

| Primary Goal | High-volume production (e.g., fuel, feed) | Sample preparation & R&D |

| Scale & Throughput | Tons per hour (continuous) | Single pellets per batch |

| Focus | Durability, power, cost-efficiency | Precision, purity, dimensional accuracy |

| Typical Input | Biomass (sawdust, agricultural waste) | Fine powders (chemicals, minerals) |

| Typical Output | Wood pellets, animal feed | Analytical samples, sputtering targets, battery electrodes |

Ready to Transform Your Materials with Precision?

Whether your project requires high-volume biomass processing or the creation of perfect analytical samples, KINTEK has the right solution for you. As a specialist in lab equipment and consumables, we provide the reliable, high-performance pellet presses that laboratories depend on for accurate R&D and sample preparation.

Let us help you achieve superior results. Contact our experts today to discuss your specific application and find the perfect press for your needs.

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

People Also Ask

- What role does a laboratory hydraulic pellet press play in fly ash utilization? Enhancing Adsorption and Flow Control

- What is the necessity of using a laboratory hydraulic press for RDF TGA? Optimize Your Thermal Analysis Accuracy

- Why is precise pressure control from a laboratory hydraulic press necessary when preparing matte cathode green bodies?

- What is the difference between sintering and compacting? A Guide to the Two-Step Powder Metallurgy Process

- What is the purpose of using a laboratory hydraulic press for LATP ceramic sheets? Enhance Solid Electrolyte Density

- What is the use of KBr in FTIR? A Key Technique for Accurate Solid Sample Analysis

- What is a hydraulic press machine used for? From Metal Forming to Lab Analysis

- What function does a uniaxial hydraulic press serve in LATP ceramic preparation? Optimize Your Solid Electrolytes