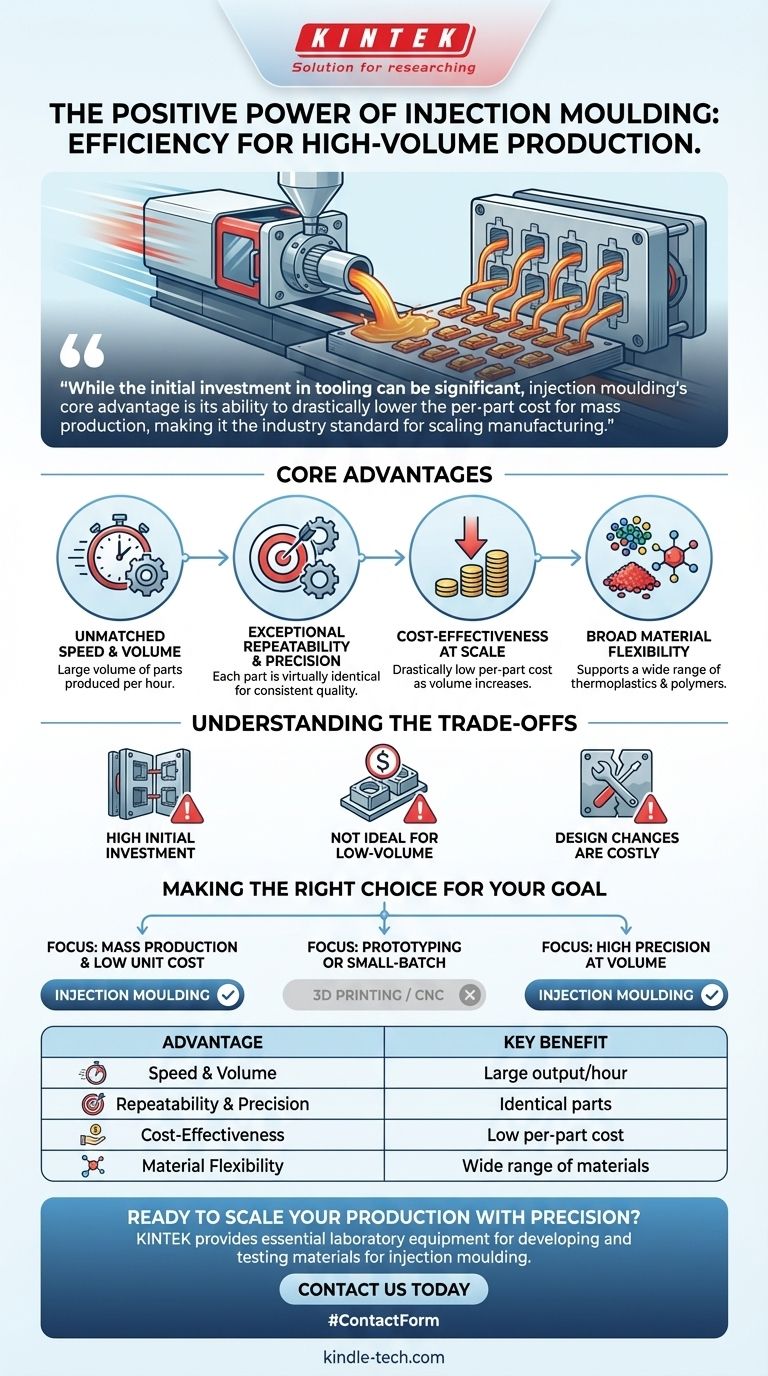

One of the primary positives of injection moulding is its exceptional efficiency for high-volume production. It is a highly repeatable process that manufactures parts with high precision, minimizing moulding costs per unit once the initial setup is complete. This method allows for a massive volume of parts to be produced per hour from a wide array of materials.

While the initial investment in tooling can be significant, injection moulding's core advantage is its ability to drastically lower the per-part cost for mass production, making it the industry standard for scaling manufacturing.

The Core Advantages of Injection Moulding

Injection moulding is a dominant force in manufacturing for several key reasons. Each advantage addresses a critical need in producing goods at scale, from cost to quality control.

Unmatched Speed and Volume

Once the mould is created and the machine is configured, the production cycle is incredibly fast. This allows for the manufacturing of a large volume of parts per hour, making it ideal for meeting high consumer demand.

Exceptional Repeatability and Precision

The process is fundamentally about consistency. Each part produced is virtually identical to the last, ensuring high precision and adherence to tight tolerances. This repeatability is critical for quality control and the reliable assembly of final products.

Cost-Effectiveness at Scale

The economics of injection moulding are its most compelling feature. While the initial cost to design and create the steel mould (tooling) is high, the cost per individual part becomes extremely low as production volume increases. The high-speed, automated nature of the process minimizes labor costs over the production run.

Broad Material Flexibility

Injection moulding is not limited to a single type of plastic. The process supports a vast range of thermoplastic and thermosetting polymers, as well as other materials like liquid silicone rubber. This allows engineers to select the perfect material for an application's specific needs, such as strength, flexibility, or temperature resistance.

Understanding the Trade-offs

To fully appreciate injection moulding's strengths, it is essential to understand its limitations. These trade-offs are what make it a specialized tool, not a universal solution.

High Initial Investment

The primary drawback is the significant upfront cost associated with creating the mould. This tooling is a complex piece of engineering that must be machined from high-strength steel, which is both time-consuming and expensive.

Not Ideal for Low-Volume Production

Because of the high initial tooling cost, injection moulding is economically impractical for prototypes or small production runs. The cost per part would be prohibitively high if spread across only a few hundred units. Processes like 3D printing are far better suited for that stage.

Design Changes are Costly

Once the steel mould is created, making changes to the part design is difficult and expensive. It often requires re-machining the tool or creating a new one entirely, which adds significant time and cost to a project.

Making the Right Choice for Your Goal

Selecting the correct manufacturing process depends entirely on your project's specific requirements for volume, budget, and speed.

- If your primary focus is mass production and low unit cost: Injection moulding is the definitive choice for producing thousands or millions of identical parts efficiently.

- If your primary focus is prototyping or small-batch production: Alternative methods like 3D printing or CNC machining offer far greater flexibility and lower upfront costs.

- If your primary focus is achieving high precision across a large volume of parts: The inherent repeatability of injection moulding makes it the most reliable option for ensuring consistent quality at scale.

Ultimately, understanding the powerful cost-per-part economics of injection moulding is the key to leveraging it effectively for your manufacturing needs.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Speed & Volume | Produces a large volume of parts per hour. |

| Repeatability & Precision | Ensures each part is virtually identical. |

| Cost-Effectiveness | Drastically lowers per-part cost at high volumes. |

| Material Flexibility | Supports a wide range of thermoplastics and polymers. |

Ready to Scale Your Production with Precision?

If your project requires high-volume manufacturing of consistent, high-quality parts, injection moulding is the definitive solution. At KINTEK, we specialize in providing the laboratory equipment and consumables essential for developing and testing materials for injection moulding processes. Our expertise ensures you can achieve the precision and efficiency your production demands.

Contact us today using the form below to discuss how KINTEK can support your laboratory and manufacturing goals. Let's optimize your process for mass production success.

Visual Guide

Related Products

- Small Injection Molding Machine for Lab Use

- Double Plate Heating Press Mold for Lab

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

People Also Ask

- What is the difference between injection molding and pressure molding? A Guide to Choosing the Right Process

- What is the application of injection moulding machine? Powering Mass Production for Complex Parts

- What is short capacity of injection Moulding machine? Optimize Your Shot Size for Flawless Parts

- What are the three 3 differences between compression molding and injection molding? Choose the Right Process for Your Project

- What is the manufacturing process of rubber molding? Injection, Compression, or Transfer Molding?