At its core, a press frame is the structural backbone of a mechanical, hydraulic, or pneumatic press. It is the massive, rigid assembly—typically comprising a bed, uprights, and a crown—engineered to absorb and contain the immense forces generated during a forming, stamping, or pressing operation. Its entire purpose is to maintain alignment and precision under extreme load.

The quality of a press frame is not measured by its size, but by its ability to resist deflection. An inferior frame that bends or "opens up" under load will produce inaccurate parts, cause premature tool wear, and ultimately compromise the entire manufacturing process.

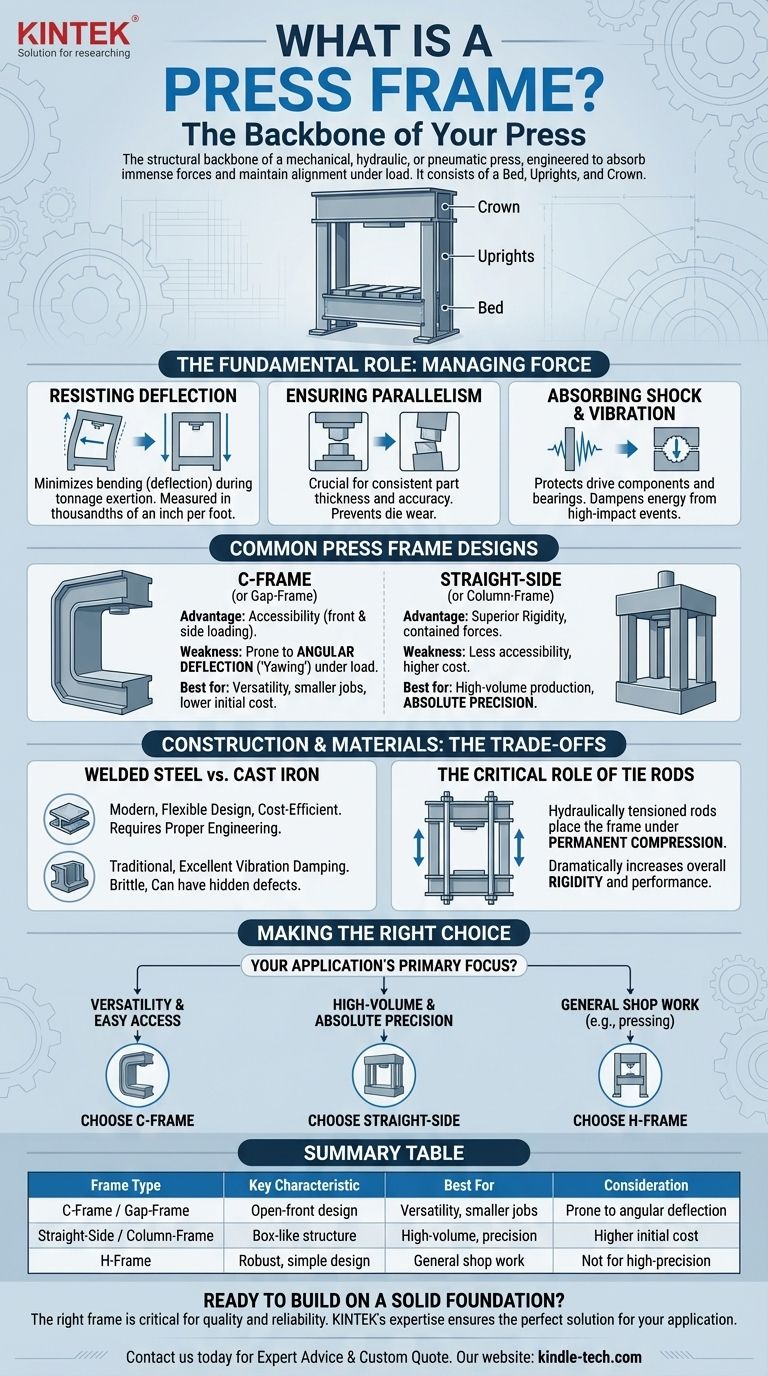

The Fundamental Role of a Press Frame: Managing Force

A press frame is not a passive housing; it is an active system for managing force and maintaining stability. Its performance dictates the quality and consistency of every part produced.

Resisting Deflection

When a press exerts tonnage, an equal and opposite force is applied to the frame, causing it to stretch and bend. This deviation from its resting state is called deflection. A well-designed frame is built with sufficient mass and structural integrity to keep deflection to an absolute minimum, often measured in thousandths of an inch per foot.

Ensuring Parallelism

The most critical consequence of frame deflection is the loss of parallelism between the moving ram and the stationary bed. If the frame deflects, the top and bottom halves of the die will no longer meet perfectly. This leads to inconsistent part thickness, burrs, and dimensional inaccuracies.

Absorbing Shock and Vibration

Stamping and forming are high-impact events that generate significant shock. The sheer mass and rigidity of the frame help to dampen this energy, protecting the press's sensitive drive components and bearings from premature failure and reducing vibration in the surrounding environment.

Common Press Frame Designs and Their Implications

The geometry of the frame is the single biggest factor in how it manages force. The two most dominant designs have distinct advantages and disadvantages.

C-Frame (or Gap-Frame)

As the name implies, this press frame is shaped like the letter "C." Its primary advantage is accessibility, allowing for easy loading and unloading of parts and tooling from the front and sides.

However, its open-front design is its greatest weakness. Under load, the "throat" of the C is prone to opening up, a phenomenon known as angular deflection or "yawing." This makes C-frame presses less suitable for high-precision or heavy-tonnage work where parallelism is critical.

Straight-Side (or Column-Frame)

A straight-side press has a solid, box-like structure with vertical columns supporting the crown directly over the bed. This design fully contains the pressing forces within the columns, which are placed under pure tension.

This construction provides far superior rigidity and resistance to deflection compared to a C-frame. Straight-side presses are the standard for high-speed, high-tonnage, and progressive die applications where precision and repeatability are non-negotiable.

Understanding the Trade-offs: Construction and Materials

The way a frame is built and the materials used are just as important as its overall design.

Welded Steel vs. Cast Iron

Most modern press frames are fabricated from welded steel plates. This method offers design flexibility and cost efficiency. Proper engineering, welding, and post-weld thermal stress relieving are crucial to prevent fatigue and ensure long-term structural integrity.

Cast iron, the traditional material, offers excellent vibration damping characteristics. However, it is more brittle than steel, and the casting process for large, complex frames can be expensive and prone to hidden defects.

The Critical Role of Tie Rods

Many high-quality straight-side presses incorporate tie rods. These are large steel rods that run vertically through the frame components (bed, columns, crown) and are hydraulically tensioned to a specific preload.

This process places the entire frame assembly under permanent compression. When the press cycles, the force generated must first overcome this massive compressive preload before it can cause any tensile stress or deflection in the frame. This dramatically increases the press's overall rigidity and is a hallmark of a high-performance machine.

Making the Right Choice for Your Application

The ideal frame is dictated entirely by the demands of your work—balancing accessibility, precision, and cost.

- If your primary focus is versatility and easy part access for smaller jobs: A C-frame press offers the best combination of accessibility and lower initial cost.

- If your primary focus is high-volume production and absolute precision: A straight-side press, especially one with pre-stressed tie rods, is essential for maintaining accuracy and maximizing die life.

- If your primary focus is general shop work like pressing bearings or straightening parts: A simple H-frame hydraulic press provides a robust and cost-efficient solution without the complexity of a production stamping press.

Ultimately, understanding the press frame is understanding the foundation upon which all part quality and process reliability are built.

Summary Table:

| Frame Type | Key Characteristic | Best For | Consideration |

|---|---|---|---|

| C-Frame / Gap-Frame | Open-front design for accessibility | Versatility, easy part loading, smaller jobs | Prone to angular deflection under load |

| Straight-Side / Column-Frame | Box-like structure for superior rigidity | High-volume production, absolute precision | Higher initial cost, less accessibility |

| H-Frame | Robust, simple design | General shop work (e.g., pressing bearings) | Not for high-precision stamping |

Ready to Build Your Process on a Solid Foundation?

The right press frame is critical for part quality, die life, and overall equipment reliability. Whether you need the accessibility of a C-frame or the precision of a straight-side press, KINTEK's expertise in lab and industrial equipment ensures you get the perfect solution for your specific application.

Contact us today to discuss your requirements, and let our specialists help you select a press that delivers the performance and durability your operation demands.

Get a Custom Quote & Expert Advice

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Double Plate Heating Press Mold for Lab

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What role does a laboratory hydraulic press play in pellet-type electrode fabrication? Enhancing Solid-State Performance

- Why is KBr used as a mulling agent in IR? Achieve Clear, Accurate Solid Sample Analysis

- What is an example of a hydraulic press? Discover the Power of Laboratory Sample Preparation

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is the use of manual hydraulic press? A Cost-Effective Tool for Lab Sample Preparation