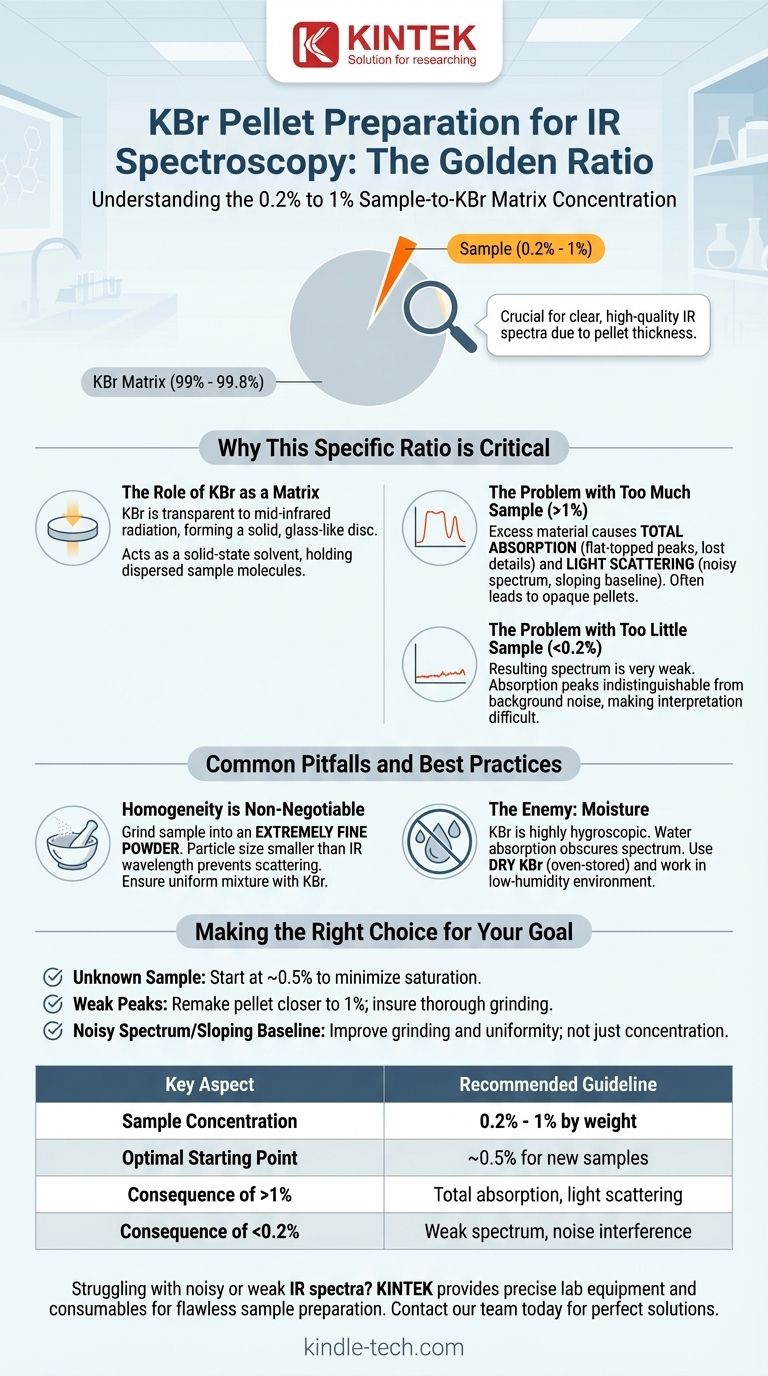

For infrared (IR) spectroscopy, the recommended concentration of your sample within the Potassium Bromide (KBr) matrix is between 0.2% and 1% by weight. This low concentration is essential because the solid KBr pellet is much thicker than a typical liquid sample cell. Adhering to this ratio is crucial for obtaining a clear, high-quality spectrum.

The core principle is to disperse a small amount of your sample evenly within a much larger amount of IR-transparent KBr. This ensures the IR beam can pass through the pellet without being completely absorbed or scattered, which are the primary causes of unusable, noisy spectral data.

Why This Specific Ratio is Critical

To understand the importance of the 0.2-1% range, we must first understand the role of KBr and the consequences of deviating from this standard.

The Role of KBr as a Matrix

Potassium Bromide is used because it is transparent to mid-infrared radiation and has a plastic-like quality under pressure, allowing it to form a solid, glass-like disc. It essentially acts as a solid-state solvent, holding your sample molecules in a fixed, dispersed state within the path of the IR beam.

The Problem with Too Much Sample

Using a sample concentration above 1% is a common mistake that leads to poor results. This excess material causes two main problems:

- Total Absorption: The sample absorbs the IR beam so strongly that little to no light reaches the detector. This results in "flat-topped" peaks where the true peak shape and position are lost.

- Light Scattering: If the sample particles are not ground finely enough or are too concentrated, they scatter the IR beam instead of letting it pass through. This leads to a noisy spectrum with a sloping, unstable baseline.

A high sample concentration also makes it physically difficult to press a clear, translucent pellet, which is necessary for good data.

The Problem with Too Little Sample

Conversely, if the sample concentration is far below 0.2%, the resulting spectrum will be very weak. The absorption peaks from your sample may be too small to be distinguished from the background noise of the instrument, making interpretation difficult or impossible.

Common Pitfalls and Best Practices

Achieving the correct ratio is only part of the process. Sample preparation technique is equally important for success.

Homogeneity is Non-Negotiable

The single most critical factor, beyond the ratio, is ensuring the sample is ground into an extremely fine powder and mixed homogeneously with the KBr. The particle size of the sample should be smaller than the wavelength of the IR light to prevent scattering effects. This is typically achieved by grinding the sample and KBr together in an agate mortar and pestle.

The Enemy: Moisture

KBr is highly hygroscopic, meaning it readily absorbs water from the atmosphere. Water has very strong IR absorption bands that can obscure important regions of your spectrum. Always use dry KBr (often stored in an oven) and prepare your pellet in a low-humidity environment if possible.

Making the Right Choice for Your Goal

Use the 0.2% to 1% range as a guideline and adjust based on your specific sample and the results you observe.

- If you are analyzing a new or unknown sample: Start at the lower end of the range, around 0.5%, to minimize the risk of signal saturation from very strong absorbers.

- If your initial spectrum shows very weak peaks: You can remake the pellet with a concentration closer to 1%, ensuring you grind thoroughly to maintain pellet clarity.

- If your spectrum has a sloping baseline or is very noisy: The problem is more likely poor grinding and light scattering, not concentration. Re-prepare the sample, focusing on achieving a finer particle size and more uniform mixture.

Mastering this simple ratio is the foundation for producing consistently clear and reliable IR spectra.

Summary Table:

| Key Aspect | Recommended Guideline |

|---|---|

| Sample Concentration | 0.2% - 1% by weight |

| Optimal Starting Point | ~0.5% for new samples |

| Consequence of Too Much Sample (>1%) | Total absorption, flat-topped peaks, light scattering |

| Consequence of Too Little Sample (<0.2%) | Weak spectrum, peaks indistinguishable from noise |

Struggling with noisy or weak IR spectra? KINTEK specializes in providing the precise lab equipment and consumables you need for flawless sample preparation. From high-quality, hygroscopic KBr to reliable pellet presses, our products are designed to help you achieve the perfect sample concentration and homogeneity every time.

Let our expertise enhance your laboratory's efficiency and data quality. Contact our team today to find the perfect solution for your IR spectroscopy needs!

Visual Guide

Related Products

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- kbr pellet press 2t

People Also Ask

- What is the role of a laboratory hydraulic press in sulfide solid-state electrolyte pellet formation? Maximize Density

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- Why is a hydraulic pellet press used for FTIR? Transform Nanofillers into Clear Data

- Why is a laboratory hydraulic press used for Li3V2(PO4)3 pellets? Optimize Solid-State Sintering for Li-ion Materials

- How does a laboratory hydraulic pellet press contribute to SiCw/2024 aluminum composite preforms? Optimize Densification