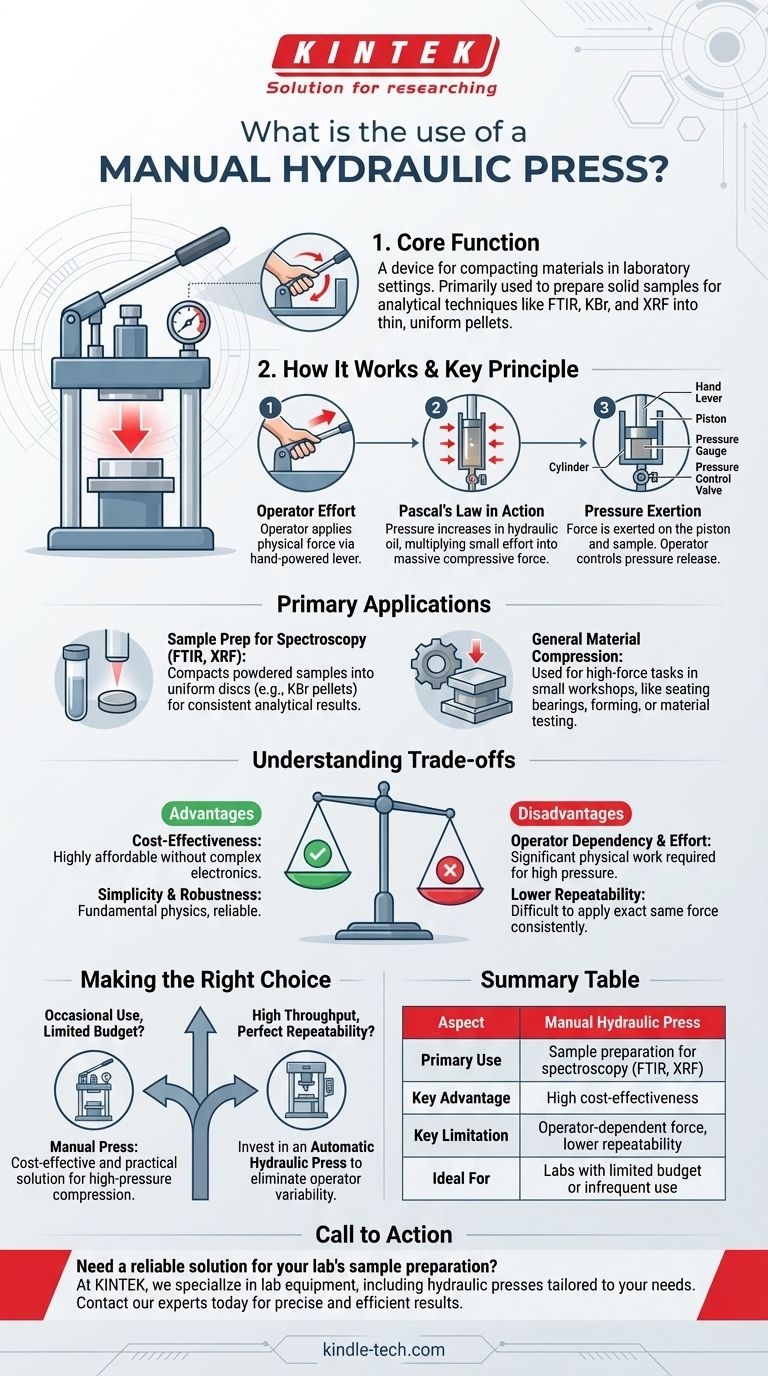

At its core, a manual hydraulic press is a device used to apply a significant amount of force to a small area, typically for compacting materials. It is most commonly found in laboratory settings for preparing solid samples for analytical techniques like FTIR, KBr, and XRF, where materials must be pressed into thin, uniform pellets. The device operates via a hand-powered lever that pressurizes hydraulic fluid to generate compressive force.

The central decision when considering a manual hydraulic press is one of cost versus consistency. It offers a highly affordable way to achieve high pressure, but at the expense of requiring physical effort and sacrificing the precise repeatability found in more expensive, automated systems.

How a Manual Press Achieves High Force

Understanding the mechanism reveals both the strengths and limitations of this tool. The design is simple, robust, and relies on fundamental physics rather than complex electronics.

The Core Principle: Pascal's Law in Action

A manual hydraulic press works by using a hand-operated pump or lever to increase the pressure of hydraulic oil within a sealed cylinder. This pressure is then exerted on a piston.

Because the force is distributed evenly throughout the fluid, a small effort applied to the pump handle is multiplied into a massive compressive force on the piston, allowing an operator to generate many tons of pressure by hand.

The Role of the Operator

Unlike an automatic press, the operator is a direct part of the system. The amount of force applied is directly related to the physical effort exerted on the hand lever.

The operator also uses a pressure release valve to decrease the force and lower the piston once the task is complete.

Key Operational Components

Essential components include the cylinder, piston, and hand lever. Most presses also feature a pressure gauge to monitor the applied load and a pressure control valve for fine adjustments. For safety, they are often equipped with polycarbonate guards.

Primary Applications and Use Cases

While versatile, the manual hydraulic press excels in environments where precision is important but high-throughput and perfect automation are not.

Sample Preparation for Spectroscopy

This is the most specialized and common use. For analytical methods like FTIR (Fourier-Transform Infrared Spectroscopy) or XRF (X-Ray Fluorescence), samples must be prepared in a uniform, compressed form, often as a KBr (Potassium Bromide) pellet.

The press compacts the powdered sample into a thin, solid disc that is ideal for analysis, ensuring consistent results by minimizing irregularities in the sample.

General Material Compression

Beyond the lab, these presses can be used in small workshops for tasks that require high force over a small area. This could include seating bearings, simple forming operations, or compressing other materials for testing or assembly.

Understanding the Critical Trade-offs

Choosing a manual press requires a clear understanding of what you gain and what you sacrifice. Its simplicity is both its greatest asset and its primary limitation.

Advantage: Cost-Effectiveness

Without motors, electronics, or complex control systems, manual presses are significantly more affordable than their automatic counterparts. This makes them an excellent choice for labs or workshops with limited budgets or infrequent need.

Disadvantage: Operator Dependency and Effort

The primary drawback is the reliance on physical effort. Applying the maximum rated tonnage (e.g., 15 or 25 tons) requires significant manual work from the operator.

The Challenge of Repeatability

Because pressure is applied by hand, it is very difficult to ensure each sample is pressed with the exact same force every time. This lack of repeatability can be a problem for sensitive scientific experiments where consistency is paramount. An automated press eliminates this variable completely.

Making the Right Choice for Your Goal

To determine if a manual hydraulic press is the correct tool, evaluate your primary requirements for throughput, budget, and consistency.

- If your primary focus is occasional use or a limited budget: The manual press is the most cost-effective and practical solution for achieving high-pressure compression.

- If your primary focus is high throughput or perfect repeatability: You should invest in an automatic hydraulic press to eliminate operator variability and ensure every sample is prepared identically.

Ultimately, the manual hydraulic press is an effective and reliable tool when its inherent limitations are understood and aligned with your operational needs.

Summary Table:

| Aspect | Manual Hydraulic Press |

|---|---|

| Primary Use | Sample preparation for spectroscopy (FTIR, XRF) |

| Key Advantage | High cost-effectiveness |

| Key Limitation | Operator-dependent force, lower repeatability |

| Ideal For | Labs with limited budget or infrequent use |

Need a reliable solution for your lab's sample preparation?

At KINTEK, we specialize in lab equipment and consumables, including hydraulic presses tailored to your specific needs. Whether you're preparing KBr pellets for FTIR or require consistent pressure for XRF analysis, our expertise ensures you get the right tool for the job.

Let us help you achieve precise and efficient results. Contact our experts today to discuss your application and find the perfect press for your laboratory!

Visual Guide

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- On which factors does hydraulic press depend? Achieve Precise Force Control for Your Applications

- What is the difference between brake press and punch press? Choosing the Right Metal Fabrication Tool

- How much PSI does a hydraulic actuator usually operate at? A Guide to Industrial & High-Pressure Ranges

- What critical process conditions does a laboratory precision hydraulic press provide for fabricating composites?

- How does temperature affect forging? Master Hot, Cold, and Warm Forging for Optimal Results

- Why are precise pressure maintenance and durability testing equipment necessary for garden waste pellets? Ensure Quality

- Why is KBr pellet used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What are the advantages of a hydraulic press over a mechanical press? Superior Control, Safety & Cost-Effectiveness