To be clear, the term "PVD diamond" is marketing language for a type of durable surface coating, not a gemstone. It does not contain any actual diamond. The name refers to a process called Physical Vapor Deposition (PVD) that applies a very hard, often dark-colored finish to a base metal like stainless steel or titanium, creating an appearance that is sometimes compared to black diamonds for its color and resilience.

The core takeaway is that "PVD diamond" is not a material but a process. It creates a strong, thin-film coating on metal that enhances its durability and changes its color, but it has no connection to the precious stone.

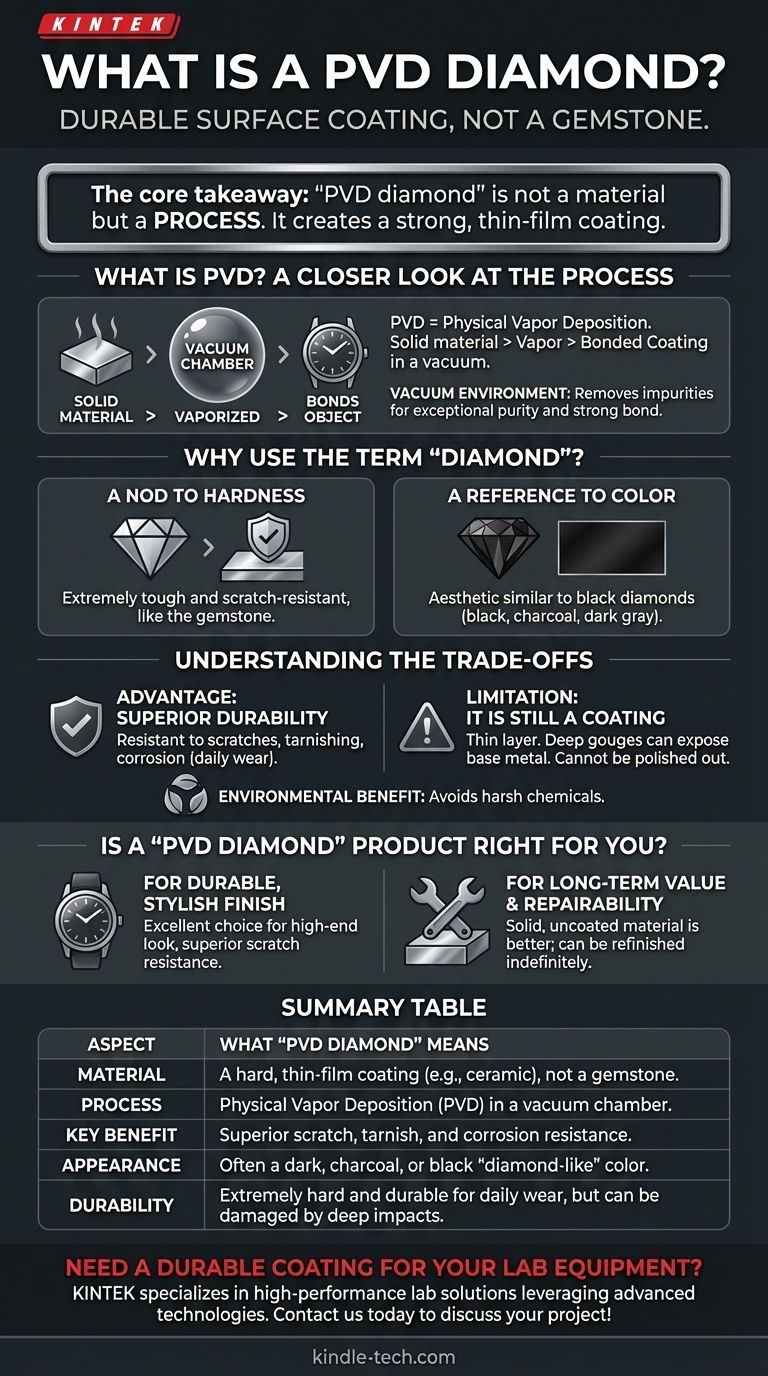

What is PVD? A Closer Look at the Process

To understand the value of a "PVD diamond" finish, you must first understand the underlying technology. The quality of the product comes from the sophistication of the manufacturing process itself.

The Meaning of PVD

PVD stands for Physical Vapor Deposition. It is an advanced coating process that takes place in a high-tech vacuum chamber.

The process involves turning a solid coating material into a vapor, which then travels through the vacuum and bonds with the target object (like a watch case or piece of jewelry) on a molecular level.

The Role of the Vacuum

Conducting this process in a vacuum is critical. It removes impurities from the air that could otherwise compromise the coating's integrity.

This clean environment ensures the resulting finish is exceptionally pure, uniform, and creates an incredibly strong bond with the surface of the base metal.

Why Use the Term "Diamond"?

The association with "diamond" is purely descriptive, intended to communicate two key properties of the finish: its hardness and its color.

A Nod to Hardness

PVD coatings are significantly harder and more corrosion-resistant than coatings applied by older methods like electroplating.

The materials used for these dark coatings are often hard ceramics. By calling the finish "PVD diamond," manufacturers are trying to convey that the surface is extremely tough and scratch-resistant, much like the gemstone.

A Reference to Color

This marketing term is most often used for coatings that are black, charcoal, or dark gray. It creates an aesthetic similar to that of black diamonds, which are popular in modern jewelry and watch design.

It is simply a way to describe a specific look, not the material composition.

Understanding the Trade-offs

While PVD is a superior coating technology, it is essential to have realistic expectations. It is a finish, not a solid material.

The Advantage: Superior Durability

Compared to traditional plating, PVD is in a different league. It is highly resistant to scratches, tarnishing, and corrosion from sweat or saltwater. This makes it an excellent choice for items that see daily wear.

The Limitation: It Is Still a Coating

Although durable, the PVD layer is very thin. A deep gouge or a significant impact can still penetrate the coating and expose the base metal underneath.

Unlike a solid material, you cannot polish out a deep scratch on a PVD-coated item without removing the finish in that area.

The Environmental Benefit

As a side benefit, PVD is an environmentally friendly process. It avoids the harsh chemicals and waste products associated with traditional electrochemical plating methods.

Is a "PVD Diamond" Product Right for You?

Understanding the terminology allows you to make a choice based on your specific goals.

- If your primary focus is a durable, stylish, and affordable finish: A PVD-coated product is an excellent choice. It offers a high-end look and superior scratch resistance for everyday items.

- If your primary focus is long-term value and repairability: A product made from a solid, uncoated material (like stainless steel) is the better investment, as it can be refinished and polished indefinitely.

By recognizing "PVD diamond" as a marker of a high-performance coating, you can confidently evaluate the product based on its true strengths: advanced engineering and resilient design.

Summary Table:

| Aspect | What 'PVD Diamond' Means |

|---|---|

| Material | A hard, thin-film coating (e.g., ceramic), not a gemstone. |

| Process | Physical Vapor Deposition (PVD) in a vacuum chamber. |

| Key Benefit | Superior scratch, tarnish, and corrosion resistance. |

| Appearance | Often a dark, charcoal, or black 'diamond-like' color. |

| Durability | Extremely hard and durable for daily wear, but can be damaged by deep impacts. |

Need a Durable Coating for Your Lab Equipment or Components?

Understanding the advanced engineering behind PVD coatings is key to selecting the right surface treatment for your applications. At KINTEK, we specialize in providing high-performance lab equipment and consumables, including solutions that leverage durable coating technologies.

Let our experts help you find the right equipment to achieve superior durability and performance for your laboratory needs.

Contact us today to discuss your project!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- CVD Diamond Optical Windows for Lab Applications

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

People Also Ask

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- What is CVD diamond coating? Grow a Super-Hard, High-Performance Diamond Layer

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance