A PVD machine is a specialized system that operates under a high vacuum to apply exceptionally thin, durable coatings onto the surface of a part. Standing for Physical Vapor Deposition, the process involves turning a solid coating material into a vapor, which then travels atom by atom to bond with the part's surface, forming a high-performance film. This technique fundamentally enhances a component's properties rather than just covering it.

A PVD machine is best understood not as a simple coater, but as a tool for engineering the surface of an object. It allows you to add properties like extreme hardness, wear resistance, or specific colors to a component without altering its underlying material or precise dimensions.

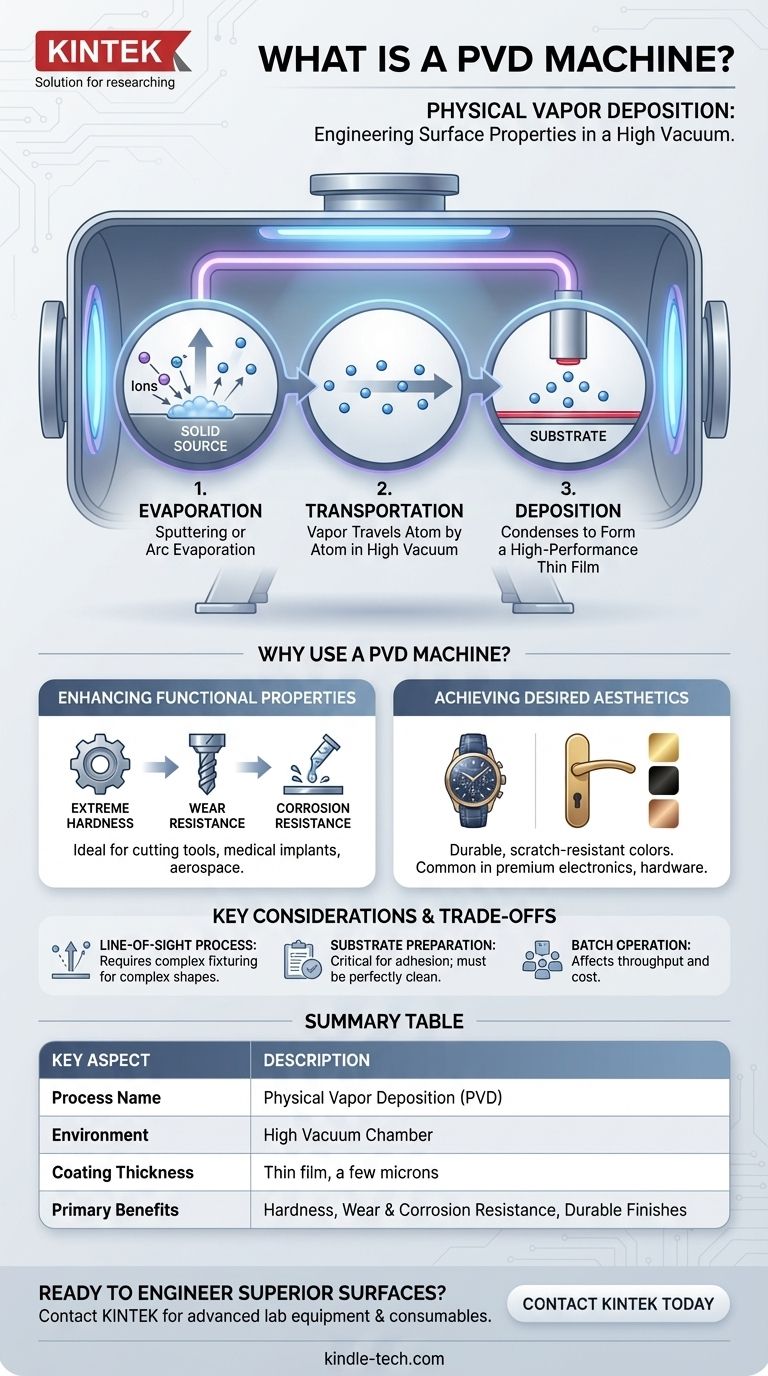

How a PVD Machine Operates: From Solid to Surface

The entire PVD process takes place inside a sealed vacuum chamber. This controlled environment is critical for the quality and adhesion of the final coating.

The Critical Role of the Vacuum

A PVD machine first pumps all the air and other atmospheric gases out of its chamber. This vacuum is essential because it eliminates contaminants like oxygen, nitrogen, and water vapor that would otherwise react with the coating material and compromise the film's integrity and bond strength.

The Three Core Stages of Deposition

Once a high vacuum is achieved, the process follows three fundamental steps.

1. Evaporation

This is the "Physical" part of PVD. A solid source material, often a high-purity metal or ceramic like Titanium Nitride, is converted into a gaseous vapor. This is typically accomplished through methods like sputtering, where the source is bombarded with energetic ions, or arc evaporation, where a high-current electric arc vaporizes the material.

2. Transportation

The vaporized atoms and molecules travel from the source material to the components being coated (known as the substrate). Inside the vacuum, this movement occurs in a straight line-of-sight trajectory, ensuring the material travels unimpeded.

3. Deposition

This is the final stage where the vaporized material condenses onto the surface of the substrates. As the atoms arrive, they form a thin, highly dense, and tightly bonded film. The machine's precise control over temperature, pressure, and time determines the coating's final thickness and structure, which are often just a few microns thick.

The Purpose: Why Use a PVD Machine?

PVD is chosen when a surface requires properties that the base material cannot provide on its own. The applications are broadly functional or decorative.

Enhancing Functional Properties

The primary driver for PVD is performance. The coatings can drastically increase a component's hardness, wear resistance, and corrosion resistance. This makes it indispensable for high-performance cutting tools, medical implants, and aerospace components where durability is non-negotiable.

Achieving a Desired Aesthetic

PVD machines can also deposit a wide range of colors with exceptional durability. Finishes like gold, black, bronze, and iridescent tones are far more resistant to scratches and fading than paint or traditional electroplating. This is why PVD is common on luxury watches, architectural hardware, and premium electronics.

Understanding the Trade-offs and Considerations

While powerful, the PVD process has inherent characteristics that must be understood for successful application.

Line-of-Sight Process

Because the coating material travels in a straight line, it can be challenging to uniformly coat complex shapes with hidden or internal surfaces. This limitation is managed through sophisticated fixturing that rotates parts during the process, but it remains a key design consideration.

Substrate Preparation is Critical

The quality of the PVD coating is entirely dependent on the quality of the surface it is applied to. Substrates must be perfectly clean, dry, and smooth. Any surface defect, oil, or microscopic particle will result in poor adhesion or a blemish in the final coating.

A Batch-Based Operation

PVD is a batch process, not a continuous one. Parts are loaded into the chamber, the process is run over several hours, and then the parts are unloaded. This affects throughput and cost, making it different from high-volume, continuous processes like coil coating or painting.

Is PVD the Right Choice for Your Application?

To decide if PVD is the correct approach, consider your primary goal.

- If your primary focus is extreme durability and wear resistance: PVD is a leading solution for extending the life of cutting tools, molds, and engine components where performance under stress is critical.

- If your primary focus is a premium, durable decorative finish: PVD provides a finish for watches, faucets, and firearms that is significantly more robust than paint or plating.

- If your primary focus is biocompatibility for medical devices: PVD is a standard process for coating implants and surgical tools to ensure they are inert and safe for use within the human body.

Ultimately, a PVD machine gives you a powerful method for precisely engineering a surface to meet specific performance and aesthetic demands.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process Name | Physical Vapor Deposition (PVD) |

| Environment | High Vacuum Chamber |

| Coating Thickness | Thin film, typically a few microns |

| Primary Benefits | Extreme hardness, wear & corrosion resistance, durable decorative finishes |

| Common Applications | Cutting tools, medical implants, aerospace components, luxury watches, architectural hardware |

| Key Consideration | Line-of-sight process; requires meticulous surface preparation |

Ready to Engineer Superior Surfaces?

Whether you're developing more durable cutting tools, biocompatible medical devices, or products with a premium, long-lasting finish, the right PVD coating solution is critical. KINTEK specializes in advanced lab equipment and consumables for surface engineering, serving the precise needs of laboratories and R&D departments.

Let our experts help you select the ideal PVD process to meet your specific performance and aesthetic goals. Contact KINTEK today to discuss your project and discover how we can enhance your product's capabilities.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

People Also Ask

- What is PECVD used for? Achieve Low-Temperature, High-Performance Thin Films

- What is the difference between CVD and PECVD? Choose the Right Thin-Film Deposition Method

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What is plasma enhanced chemical vapor deposition? Achieve Low-Temperature, High-Quality Thin Films

- What is plasma enhanced chemical vapour deposition process? Unlock Low-Temperature, High-Quality Thin Films