In the context of thin films, adhesion is the force that binds a deposited film to the surface of the underlying material, known as the substrate. It is the fundamental property that determines whether a coating will successfully stick and perform its function or fail by peeling or flaking off. Without sufficient adhesion, all other designed characteristics of the film—such as its durability, optical transparency, or electrical conductivity—are rendered completely useless.

The central challenge is not just achieving a bond, but ensuring that the adhesive forces between the film and substrate are strong enough to overcome the internal stresses within the film and any external forces the component will experience during its operational life.

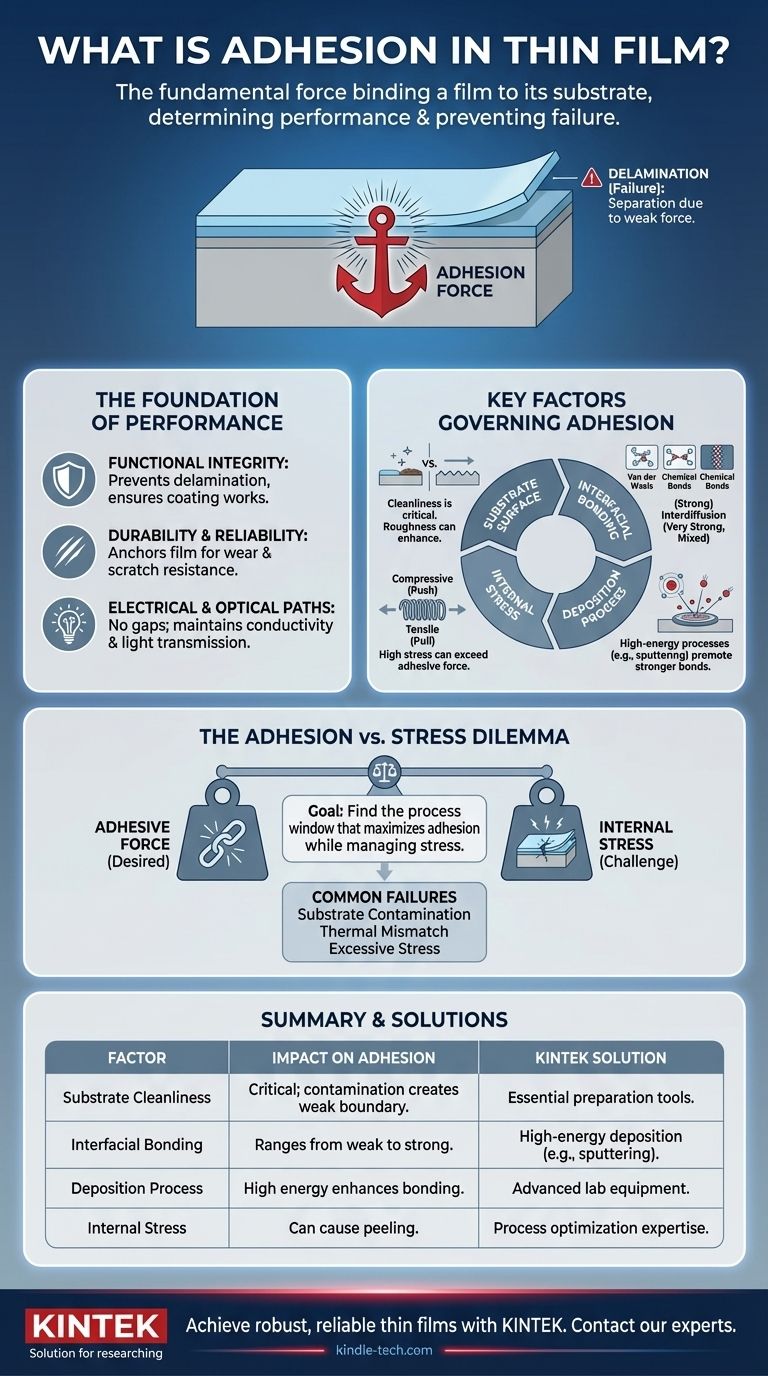

The Foundation of Performance: Why Adhesion Matters

A thin film is only as good as its bond to the substrate. While properties like hardness or conductivity are designed for a specific application, adhesion is the non-negotiable prerequisite that allows those properties to be realized.

Ensuring Functional Integrity

At its most basic level, adhesion prevents delamination—the physical separation of the film from the substrate. If a film delaminates, it can no longer perform its intended function.

Enabling Durability and Reliability

Properties like scratch resistance are directly dependent on strong adhesion. A hard coating that is not well-adhered will simply chip away when scratched, offering no real protection. Good adhesion is the anchor that allows a film to withstand mechanical wear and tear over its lifetime.

Impacting Electrical and Optical Paths

For electronic or photonic applications, delamination creates a physical gap that disrupts the system. An electrical current cannot flow across a delaminated conductive trace, and light cannot pass uniformly through a detached optical coating, leading to immediate device failure.

Key Factors That Govern Adhesion

Achieving strong adhesion is a complex interplay between the substrate, the film material, and the deposition process itself. It is not a single property but the result of several contributing factors.

The Substrate Surface

The condition of the substrate is arguably the most critical factor. A surface that is not meticulously clean, free of organic residues, particulates, or native oxides, will create a weak boundary layer that prevents a strong bond from forming.

Surface roughness can also play a role. A slightly roughened surface can increase the surface area for bonding and provide a degree of mechanical interlocking, which often enhances adhesion.

Interfacial Bonding Mechanisms

The actual bond is formed through one or more mechanisms at the film-substrate interface. These can range from weak van der Waals forces (physisorption) to much stronger chemical bonds (chemisorption).

In some cases, a process of interdiffusion can occur, where atoms from the film and substrate mix to form a graded interface, resulting in an exceptionally strong, robust bond.

The Deposition Process

How the film is grown has a profound impact. High-energy deposition processes like sputtering cause atoms to arrive at the substrate with significant kinetic energy. This energy can help clean the surface and promote the formation of stronger chemical bonds or a denser film structure, improving adhesion.

Internal Stress

Nearly all thin films possess some level of internal stress, which arises during the deposition process. This stress can be either compressive (pushing inward) or tensile (pulling outward). If the internal stress is high enough, it can exceed the adhesive force, causing the film to spontaneously peel or buckle.

Understanding the Trade-offs and Failure Modes

Optimizing for adhesion is rarely straightforward and often involves balancing competing factors. Understanding these compromises is key to troubleshooting failures.

The Adhesion vs. Stress Dilemma

Often, the very deposition parameters that enhance adhesion (like high particle energy) also increase the internal stress within the film. A process might create a strong chemical bond at the interface but build up so much stress that the film tears itself apart. The goal is to find a process window that maximizes adhesion while keeping internal stress at a manageable level.

Common Causes of Adhesion Failure

When a film delaminates, the cause can almost always be traced back to a few key areas. The most common culprit is substrate contamination. Other frequent causes include a significant mismatch in thermal expansion between the film and substrate, or internal stress becoming too high.

The Challenge of Measurement

Quantifying adhesion is notoriously difficult. Simple methods like the "tape test" are qualitative and only effective for identifying very poor adhesion. More quantitative methods like the scratch test or pull-off test provide more data but can be complex to interpret and may not perfectly replicate real-world failure conditions.

Making the Right Choice for Your Goal

Achieving robust adhesion requires tailoring your process to your specific application. The optimal approach depends entirely on what you are trying to achieve.

- If your primary focus is mechanical durability (e.g., hard coatings): Prioritize aggressive substrate pre-cleaning and consider using a high-energy deposition process to promote a dense film structure and strong interfacial bonding.

- If your primary focus is sensitive electronics or optics: Emphasize meticulous contamination control and select film and substrate materials with similar thermal expansion coefficients to minimize stress during temperature changes.

- If you are diagnosing an adhesion failure: Always begin by investigating the cleanliness of your substrate and the interface between the film and substrate. Analyze process parameters to understand and potentially mitigate internal stress.

Ultimately, viewing adhesion not as a feature but as the fundamental platform for your thin film is the critical first step toward a successful and reliable application.

Summary Table:

| Key Factor | Impact on Adhesion |

|---|---|

| Substrate Cleanliness | Critical; contamination creates a weak boundary layer. |

| Interfacial Bonding | Ranges from weak van der Waals forces to strong chemical bonds. |

| Deposition Process | High-energy processes (e.g., sputtering) can enhance bonding. |

| Internal Stress | High stress can exceed adhesive force, causing peeling. |

Achieve robust, reliable thin films with KINTEK.

Strong adhesion is the non-negotiable foundation for any coating's success. Whether you're developing wear-resistant surfaces, advanced electronics, or precision optics, KINTEK's expertise in lab equipment and consumables can help you optimize your process. From high-energy sputtering systems to essential substrate preparation tools, we provide the solutions you need to master interfacial bonding and prevent delamination.

Let's build a stronger bond together. Contact our experts today to discuss your specific application challenges.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Vacuum Cold Mounting Machine for Sample Preparation

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

People Also Ask

- Are carbon nanotubes stronger than graphene? Choosing the Right Carbon Nanomaterial for Your Application

- Is it possible during the synthesis of CNTs to determine its chirality? Master the Challenge of CNT Purity Control

- What method is used to make thin films? A Guide to Chemical and Physical Deposition

- What is a precursor for a chemical vapour deposition? The Essential Compound for Thin Film Growth

- What is the principle of sputtering deposition? A Guide to High-Performance Thin Film Coating

- What is the top-down method of graphene synthesis? A Guide to Scalable Graphene Production

- What are the properties and common applications of synthetic diamonds? Engineering the Future of Industrial Precision

- What are some common materials synthesized using CVD? Explore Nanostructures, Coatings, and High-Purity Films