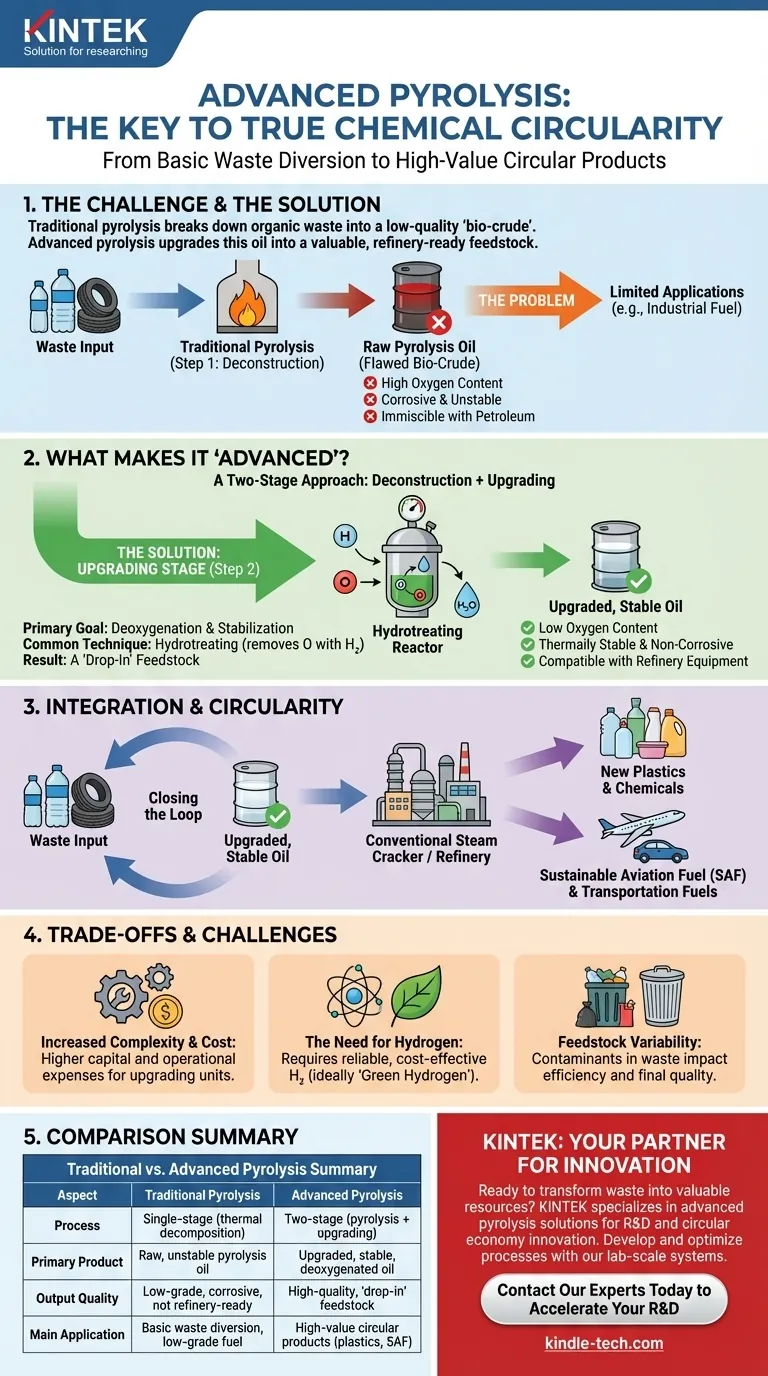

In the pursuit of a circular economy, advanced pyrolysis represents a crucial evolution of a foundational technology. While traditional pyrolysis breaks down organic waste like plastics into a basic bio-oil, advanced pyrolysis adds critical post-processing steps to upgrade this oil, removing impurities and stabilizing it to create a high-quality feedstock suitable for producing new chemicals and fuels.

The core difference isn't in the initial breakdown of waste, but in what happens next. Advanced pyrolysis solves the inherent quality problems of raw pyrolysis oil, transforming it from a difficult, low-grade substance into a valuable commodity compatible with existing industrial infrastructure.

First, Understanding Traditional Pyrolysis

To grasp what makes a process "advanced," we must first understand the baseline. Traditional pyrolysis is a powerful concept with inherent limitations.

The Basic Process: Deconstruction with Heat

Pyrolysis is thermal decomposition in the absence of oxygen. Organic materials, such as mixed plastic waste, old tires, or biomass, are heated to high temperatures in a reactor.

This process breaks down long polymer chains into smaller, less complex molecules, yielding three primary outputs: a gas (syngas), a solid (char), and a liquid (pyrolysis oil).

The Primary Product: A Flawed "Bio-Crude"

The main product of interest is typically the pyrolysis oil, sometimes called bio-crude. This liquid contains the building blocks that can potentially be used to make new products.

The Inherent Problem: Low-Quality Oil

This raw pyrolysis oil is fundamentally different from conventional crude oil. As the reference material notes, it has a high oxygen content.

This oxygen makes the oil corrosive, thermally unstable, and prone to thickening into sludge when exposed to air. It also does not mix well with petroleum fuels, making it incompatible with standard refinery equipment.

What Makes Pyrolysis "Advanced"?

Advanced pyrolysis is not a single, proprietary method. It is a category of solutions defined by the addition of a second stage focused on upgrading the raw pyrolysis oil.

A Two-Stage Approach: Deconstruction and Upgrading

The process is best understood as two distinct phases.

- Deconstruction: Traditional pyrolysis breaks down the waste into raw oil.

- Upgrading: A secondary chemical process refines that raw oil.

The Goal: Deoxygenation and Stabilization

The primary objective of the upgrading stage is to remove the oxygen (deoxygenation) and other impurities. This is the key step that addresses the instability, corrosiveness, and immiscibility of the raw oil.

Common Upgrading Technique: Hydrotreating

The most common upgrading method is hydrotreating. In this process, the raw pyrolysis oil is reacted with hydrogen at elevated pressure and temperature in the presence of a catalyst.

The hydrogen atoms bond with the oxygen atoms, creating water (H₂O), which is then easily separated. This simultaneously removes oxygen and stabilizes the hydrocarbon molecules.

The Result: A "Drop-In" Feedstock

The final product of advanced pyrolysis is a stable, deoxygenated oil. This upgraded oil is high-quality enough to be a "drop-in" feedstock for a conventional steam cracker or refinery.

This means it can be integrated directly into existing industrial infrastructure to produce new plastics or blended into transportation fuels, truly closing the loop on a circular economy.

Understanding the Trade-offs and Challenges

While powerful, advanced pyrolysis is not a silver bullet. It presents its own set of technical and economic hurdles.

Increased Complexity and Cost

Adding a secondary upgrading stage introduces significant capital and operational costs. Hydrotreating units, for example, are complex chemical reactors that require specialized equipment and careful management.

The Need for Hydrogen

Hydrotreating is dependent on a reliable and cost-effective source of hydrogen. The environmental footprint of this hydrogen is a critical factor; for the process to be truly "green," the hydrogen should be produced using renewable energy ("green hydrogen").

Feedstock Variability

The quality and consistency of the initial plastic waste feedstock remain a major challenge. Contaminants can impact the efficiency of both the pyrolysis and upgrading stages, affecting the quality of the final product.

Making the Right Choice for Your Goal

Understanding this distinction is critical for setting realistic expectations for waste-to-value projects.

- If your primary focus is basic waste diversion: Traditional pyrolysis may be sufficient if the goal is simply to reduce landfill volume and the resulting oil can be used for lower-grade applications like industrial heating fuel.

- If your primary focus is creating high-value circular products: Advanced pyrolysis is non-negotiable. It is the only way to produce a refinery-ready feedstock for making new polymers or sustainable aviation fuel.

- If your primary focus is investment and scalability: Your analysis must account for the entire advanced process, including the cost and sourcing of hydrogen and the complex logistics of securing a consistent waste feedstock.

Ultimately, advanced pyrolysis represents the necessary leap from simple waste recycling to true chemical circularity.

Summary Table:

| Aspect | Traditional Pyrolysis | Advanced Pyrolysis |

|---|---|---|

| Process | Single-stage thermal decomposition | Two-stage: pyrolysis + upgrading |

| Primary Product | Raw, unstable pyrolysis oil (bio-crude) | Upgraded, stable, deoxygenated oil |

| Key Step | Heating waste in absence of oxygen | Hydrotreating to remove oxygen/impurities |

| Output Quality | Low-grade, corrosive, not refinery-ready | High-quality, 'drop-in' feedstock for refineries |

| Main Application | Basic waste diversion, low-grade fuel | High-value circular products (new plastics, SAF) |

Ready to transform your waste into valuable resources? KINTEK specializes in advanced pyrolysis solutions for laboratories and research facilities focused on sustainable materials and circular economy innovation. Our expertise in lab-scale pyrolysis systems can help you develop and optimize processes to create high-quality, refinery-ready feedstocks from plastic waste. Contact our experts today to explore how our equipment can accelerate your R&D and contribute to a sustainable future.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

People Also Ask

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time