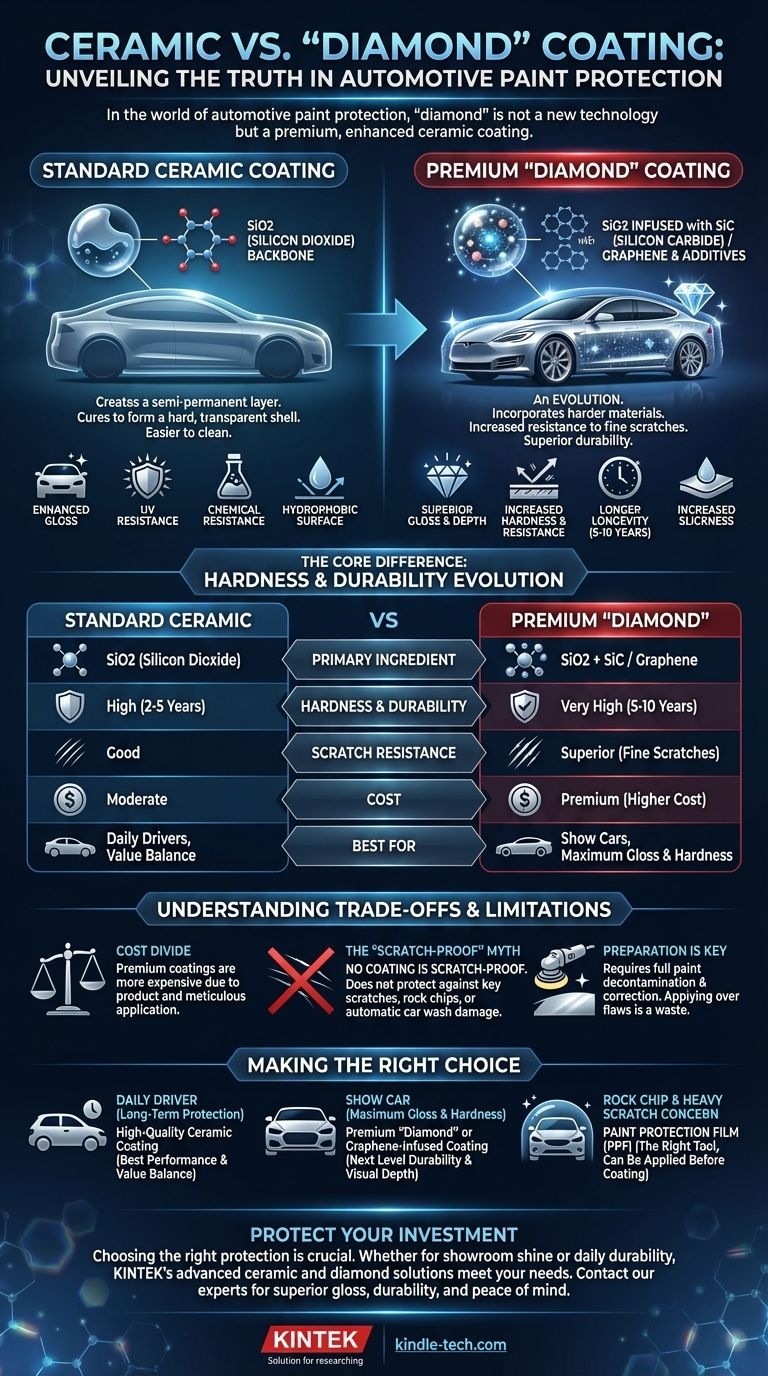

In the world of automotive paint protection, a "diamond" coating is not a fundamentally different technology but is best understood as a premium, enhanced version of a ceramic coating. While standard ceramic coatings use Silicon Dioxide (SiO2) as their backbone, high-end coatings marketed as "diamond" or "graphene" are advanced ceramic formulas infused with materials like silicon carbide (SiC) or other proprietary additives to significantly increase hardness and durability.

The core takeaway is that you are not choosing between two different categories of products. You are choosing between a standard professional-grade product (ceramic) and a premium, more robust version of that same product ("diamond"), which comes with a higher cost but offers enhanced performance.

What is a Standard Ceramic Coating?

A ceramic coating is a liquid polymer that is applied by hand to the exterior of a vehicle. It chemically bonds with the vehicle's factory paint, creating a semi-permanent layer of protection.

The Core Technology: SiO2

The primary active ingredient in most ceramic coatings is Silicon Dioxide (SiO2). When applied, this liquid formula cures to form a hard, transparent shell that is more durable than traditional waxes or sealants.

The Primary Benefits

This protective layer provides significant benefits, including enhanced gloss, UV resistance to prevent paint oxidation, and chemical resistance against contaminants like bird droppings and acid rain. It also creates a hydrophobic surface, causing water to bead and sheet off, making the car easier to clean.

Demystifying "Diamond" Coatings

The term "diamond" is primarily a marketing descriptor used to signify a top-tier product within the ceramic coating family. It highlights a key improvement: hardness.

An Evolution, Not a Revolution

Think of these products as an evolution. They use the same foundational liquid polymer technology as standard ceramics but incorporate more advanced and durable materials into their chemical matrix.

The Hardness Factor: SiC and Graphene

The "diamond" claim comes from infusing the SiO2 base with harder materials like Silicon Carbide (SiC). SiC is an extremely hard synthetic material, and its presence in the formula increases the coating's resistance to fine scratches and swirl marks. Some brands may also use graphene or other nanocomposites to achieve similar results.

Beyond Hardness: Enhanced Performance

These premium formulas often deliver more than just hardness. They can provide a deeper level of gloss, increased slickness of the paint surface, and superior longevity, often lasting for 5-10 years with proper maintenance, compared to the 2-5 year lifespan of many standard ceramics.

Understanding the Trade-offs

Choosing the right coating requires looking past the marketing and understanding the practical differences in cost and performance.

The Cost Divide

The most significant trade-off is cost. A professional application of a premium "diamond" or graphene-infused coating will be substantially more expensive than a standard ceramic coating due to both the cost of the product and the more meticulous application it may require.

The Myth of "Scratch-Proof"

It is critical to understand that no coating is scratch-proof. While a harder "diamond" coating offers superior resistance to minor wash-induced swirl marks, it will not protect your paint from key scratches, rock chips, or automatic car wash damage. That level of protection requires Paint Protection Film (PPF).

The Importance of Preparation

The final result of any coating is only as good as the surface it's applied to. Both standard and premium coatings require a full paint decontamination and correction process to remove any existing imperfections. Applying an expensive coating over flawed paint is a waste of money.

Making the Right Choice for Your Vehicle

Your decision should be based on your vehicle, your budget, and your performance expectations.

- If your primary focus is excellent, long-term protection on a daily driver: A high-quality, professionally installed ceramic coating offers the best balance of performance and value.

- If your primary focus is maximum gloss and hardness for a show car or high-end vehicle: A "diamond" or graphene-infused coating will provide that next level of durability and visual depth, provided you are comfortable with the premium cost.

- If you are concerned about rock chips and heavier scratches: Neither coating is the right tool; you should be looking into Paint Protection Film (PPF), which can be applied before a coating.

Ultimately, the best choice is an informed one based on the quality of the product and its installer, not just the marketing name on the bottle.

Summary Table:

| Feature | Standard Ceramic Coating | Premium "Diamond" Coating |

|---|---|---|

| Primary Ingredient | Silicon Dioxide (SiO2) | SiO2 + Silicon Carbide (SiC)/Graphene |

| Hardness & Durability | High (2-5 years) | Very High (5-10 years) |

| Scratch Resistance | Good | Superior |

| Cost | Moderate | Premium |

| Best For | Daily drivers, value balance | Show cars, maximum gloss & hardness |

Protect Your Investment with the Right Coating

Choosing the right paint protection is crucial for maintaining your vehicle's value and appearance. Whether you're a car enthusiast seeking showroom shine or a daily driver owner looking for durable protection, KINTEK's advanced ceramic and diamond coating solutions are tailored to meet your needs. Our high-performance coatings provide long-lasting defense against UV rays, chemicals, and environmental contaminants, ensuring your paint stays pristine for years.

Ready to enhance your vehicle's protection? Contact our experts today for a personalized consultation and discover how KINTEK's specialized coatings can deliver superior gloss, durability, and peace of mind for your prized possession.

Visual Guide

Related Products

- Laboratory CVD Boron Doped Diamond Materials

- CVD Diamond Domes for Industrial and Scientific Applications

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

People Also Ask

- What is the carbon footprint of diamond mining? Uncovering the True Environmental and Ethical Cost

- Why are non-active BDD anodes selected for wastewater treatment? Achieve Total Pollutant Mineralization

- What is the function of chemical vapor deposition (CVD) equipment? Precision Growth for BDD Electrodes

- What is the purpose of performing anodic polarization on BDD electrodes? Ensure Accurate & Reproducible Research Results

- What physical conditions does an HPHT press provide for BDD synthesis? Achieve Extreme 5 GPa & 1800 K Conditions