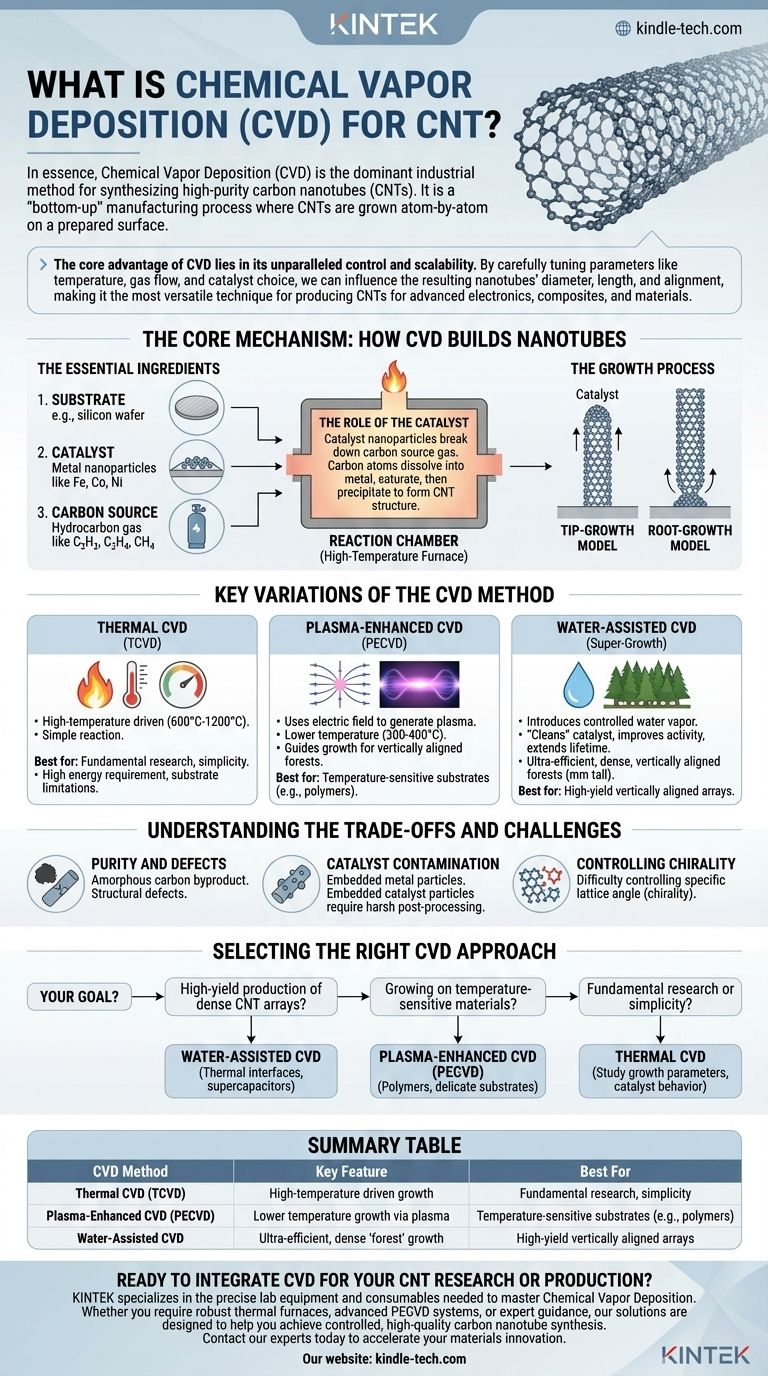

In essence, Chemical Vapor Deposition (CVD) is the dominant industrial method for synthesizing high-purity carbon nanotubes (CNTs). It is a "bottom-up" manufacturing process where CNTs are grown atom-by-atom on a prepared surface. This is achieved by introducing a carbon-containing gas into a high-temperature furnace, where a metal catalyst breaks the gas molecules apart and rebuilds the carbon into the cylindrical structure of a nanotube.

The core advantage of CVD lies in its unparalleled control and scalability. By carefully tuning parameters like temperature, gas flow, and catalyst choice, we can influence the resulting nanotubes' diameter, length, and alignment, making it the most versatile technique for producing CNTs for advanced electronics, composites, and materials.

The Core Mechanism: How CVD Builds Nanotubes

Chemical Vapor Deposition for CNTs relies on a precise interplay of three essential components inside a reaction chamber, typically a quartz tube furnace.

The Essential Ingredients

The process fundamentally requires three things:

- A substrate, which is the base material on which the CNTs will grow (e.g., a silicon wafer).

- A catalyst, usually a thin layer of metal nanoparticles (like iron, cobalt, or nickel) deposited onto the substrate.

- A carbon source, which is a hydrocarbon gas (such as acetylene, ethylene, or methane) that will be broken down to provide the carbon atoms.

The Role of the Catalyst

The catalyst nanoparticles are the "seeds" from which the nanotubes grow. At high temperatures, these tiny metal particles become active, breaking down the carbon source gas molecules that flow over them.

Carbon atoms then dissolve into and saturate the metal nanoparticle. Once the nanoparticle can hold no more carbon, the carbon begins to precipitate out in a stable, organized structure—forming the hexagonal lattice of a graphene sheet that curls into a tube.

The Growth Process

Two primary models describe how the tube emerges from the catalyst: the tip-growth model and the root-growth model.

In tip-growth, the catalyst particle lifts off the substrate and travels at the leading edge of the growing nanotube. In root-growth, the catalyst remains anchored to the substrate, and the nanotube extrudes upwards from it. The specific outcome depends on the adhesion between the catalyst and the substrate.

Key Variations of the CVD Method

The term CVD encompasses several specialized techniques, each optimized for different goals.

Thermal CVD (TCVD)

This is the most straightforward form. The reaction is driven purely by high temperatures, typically ranging from 600°C to 1200°C. Its simplicity makes it excellent for fundamental research, but the high energy requirement can limit the types of substrates that can be used.

Plasma-Enhanced CVD (PECVD)

PECVD uses an electric field to generate a plasma (an ionized gas) within the chamber. This plasma helps break down the carbon source gas molecules much more efficiently, allowing the process to run at significantly lower temperatures (as low as 200-400°C).

A major advantage of PECVD is that the electric field can guide the growth of the CNTs, resulting in highly organized, vertically aligned nanotube forests.

Water-Assisted CVD

Also known as "Super-Growth" CVD, this highly effective technique introduces a very small, controlled amount of water vapor into the reaction chamber. The water acts as a weak oxidizing agent that selectively removes amorphous carbon buildup.

This process "cleans" the catalyst particles, dramatically improving their activity and extending their lifetime. The result is the ultra-efficient growth of incredibly dense, vertically aligned CNT forests that can be several millimeters tall.

Understanding the Trade-offs and Challenges

While CVD is powerful, it is essential to understand its limitations.

Purity and Defects

The process can create unwanted byproducts, such as amorphous carbon, which coats the nanotubes and degrades their properties. The high-temperature growth can also introduce structural defects into the nanotube walls, affecting their mechanical strength and electrical conductivity.

Catalyst Contamination

After growth, the metal catalyst particles remain embedded in the CNTs (either at the tip or the root). For many applications, especially in electronics and biology, these impurities must be removed through harsh post-processing steps, such as acid washing, which can damage the nanotubes.

Controlling Chirality

The single biggest challenge in CNT synthesis is controlling chirality—the specific angle of the carbon lattice. This property determines whether a CNT behaves like a metal or a semiconductor. To date, no CVD method offers precise, scalable control over chirality, and as-grown samples are always a mix of types.

Selecting the Right CVD Approach

Your choice of CVD method should be directly tied to your end goal.

- If your primary focus is high-yield production of dense CNT arrays: Water-assisted CVD is the leading method for creating vertically aligned 'forests' for applications like thermal interfaces and supercapacitors.

- If your primary focus is growing on temperature-sensitive materials: Plasma-enhanced CVD (PECVD) is the best choice as it operates at significantly lower temperatures, enabling growth on polymers and other delicate substrates.

- If your primary focus is fundamental research or simplicity: Thermal CVD provides a straightforward, cost-effective platform for studying growth parameters and catalyst behavior.

By mastering the interplay of its core components, CVD provides the most powerful platform for engineering carbon nanotubes for next-generation materials and devices.

Summary Table:

| CVD Method | Key Feature | Best For |

|---|---|---|

| Thermal CVD (TCVD) | High-temperature driven growth | Fundamental research, simplicity |

| Plasma-Enhanced CVD (PECVD) | Lower temperature growth via plasma | Temperature-sensitive substrates (e.g., polymers) |

| Water-Assisted CVD | Ultra-efficient, dense 'forest' growth | High-yield vertically aligned arrays |

Ready to Integrate CVD for Your CNT Research or Production?

KINTEK specializes in the precise lab equipment and consumables needed to master Chemical Vapor Deposition. Whether you require robust thermal furnaces, advanced PECVD systems for delicate substrates, or expert guidance on catalyst selection, our solutions are designed to help you achieve controlled, high-quality carbon nanotube synthesis.

Contact our experts today to discuss how we can support your specific laboratory needs and accelerate your materials innovation.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

People Also Ask

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods