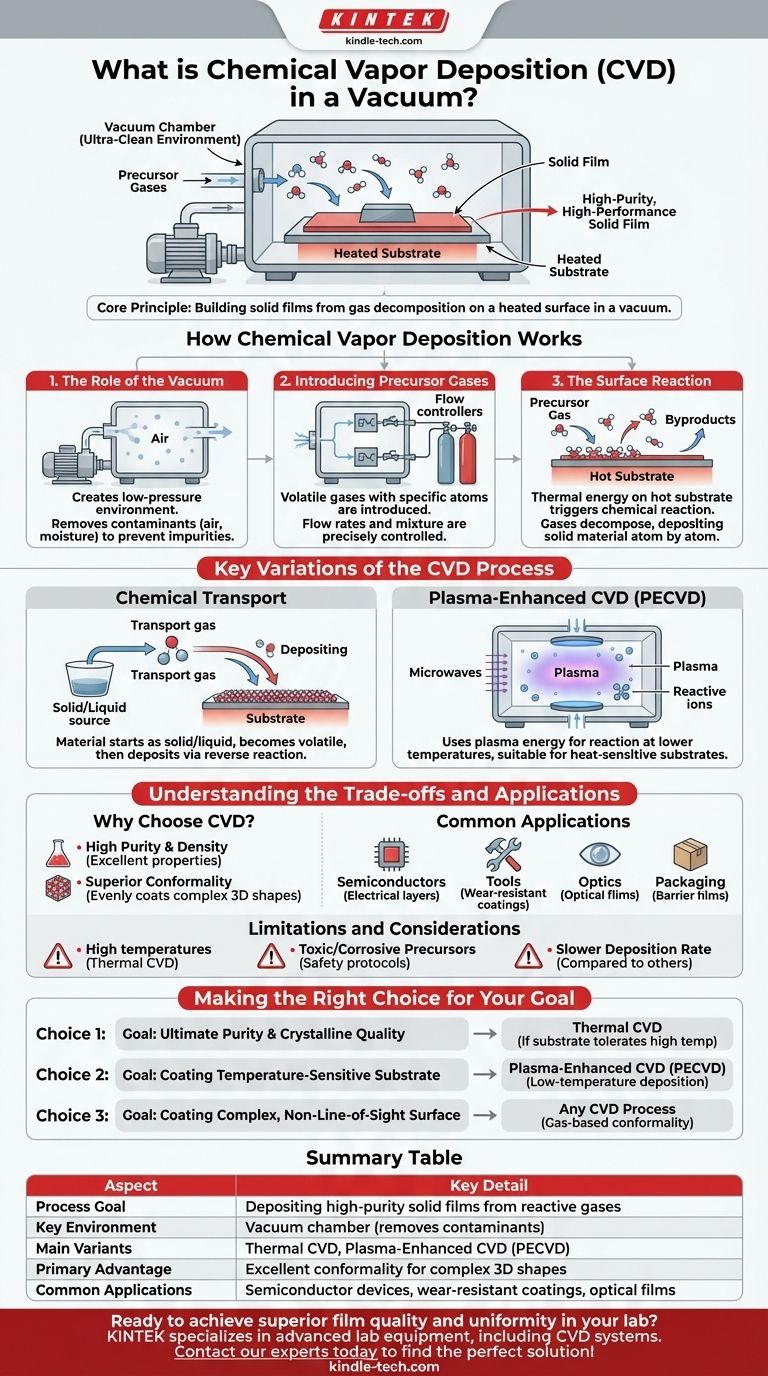

At its core, chemical vapor deposition (CVD) in a vacuum is a sophisticated process for building high-purity, high-performance solid films from a gas. It involves introducing specific reactive gases, known as precursors, into a vacuum chamber. These gases react and decompose on a heated surface (the substrate), depositing an extremely thin and uniform coating of the desired material.

The vacuum is not a passive element; it is the critical enabler. By removing air, moisture, and other contaminants, the vacuum creates an ultra-clean environment that prevents contamination and allows the precise chemical reactions necessary for high-quality film deposition to occur.

How Chemical Vapor Deposition Works

The CVD process can be broken down into three fundamental stages, all of which rely on the carefully controlled vacuum environment.

The Role of the Vacuum

The first step is creating a vacuum inside a reaction chamber. This removes unwanted atmospheric gases that could react with the precursors and cause impurities in the final film.

This controlled, low-pressure environment is essential for ensuring the purity and desired properties of the deposited coating.

Introducing the Precursor Gases

Once the chamber is under vacuum, one or more volatile precursor gases are introduced. These gases contain the specific atoms that will form the final solid film.

The flow rates and mixture of these gases are precisely controlled to determine the final composition of the coating.

The Surface Reaction

The part to be coated, or substrate, is heated to a specific temperature. When the precursor gases come into contact with this hot surface, the thermal energy triggers a chemical reaction.

The gases decompose, depositing the desired solid material onto the substrate atom by atom. Gaseous byproducts from the reaction are then pumped out of the chamber.

Key Variations of the CVD Process

While the basic principle remains the same, different methods can be used to initiate and control the chemical reaction, each suited for different materials and applications.

Chemical Transport

In some methods, the material to be deposited starts as a solid or liquid. It reacts with a transport gas in one part of the chamber to become volatile.

This new gas is then transported to the substrate, where a reverse reaction, often triggered by a different temperature, causes the desired material to deposit out of the gas phase.

Plasma-Enhanced CVD (PECVD)

Instead of relying solely on high temperatures, this method uses an energy source like microwaves to generate plasma inside the chamber.

This plasma is an energized gas containing highly reactive ions and molecular fragments. These reactive species allow the deposition reaction to occur at much lower temperatures, making it suitable for heat-sensitive substrates like plastics.

Understanding the Trade-offs and Applications

CVD is a powerful but specialized technique. Understanding its advantages and where it is applied is key to appreciating its value.

Why Choose CVD?

The primary advantage of CVD is its ability to produce highly pure, dense, and uniform coatings.

Because the deposition occurs from a gas phase, the process has excellent conformality. This means it can evenly coat complex, three-dimensional shapes and intricate internal surfaces, which is difficult for line-of-sight deposition methods.

Common Applications

CVD is an industrial-scale process used to create films with specific functional properties.

These include wear-resistant and corrosion-protective coatings for tools, optical films for lenses, electrically conducting layers for solar cells and semiconductor devices, and barrier films for packaging.

Limitations and Considerations

Traditional thermal CVD often requires very high temperatures, which can damage certain substrate materials. While PECVD solves this, it adds complexity to the equipment.

Furthermore, the precursor chemicals can be expensive, toxic, or corrosive, requiring careful handling and safety protocols. The deposition rate can also be slower than some other coating technologies.

Making the Right Choice for Your Goal

Selecting the right deposition process depends entirely on the material you need to deposit and the substrate you are working with.

- If your primary focus is ultimate purity and crystalline quality: Traditional thermal CVD is often the superior choice, provided your substrate can tolerate high temperatures.

- If your primary focus is coating a temperature-sensitive substrate: Plasma-Enhanced CVD (PECVD) is the necessary approach, as it enables high-quality deposition at much lower temperatures.

- If your primary focus is coating a complex, non-line-of-sight surface: The gas-based nature of any CVD process provides the excellent conformality needed for a uniform coating.

Ultimately, chemical vapor deposition offers unparalleled control over material synthesis at the atomic level, enabling the creation of advanced functional surfaces.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process Goal | Depositing high-purity solid films from reactive gases |

| Key Environment | Vacuum chamber (removes contaminants) |

| Main Variants | Thermal CVD, Plasma-Enhanced CVD (PECVD) |

| Primary Advantage | Excellent conformality for complex 3D shapes |

| Common Applications | Semiconductor devices, wear-resistant coatings, optical films |

Ready to achieve superior film quality and uniformity in your lab? KINTEK specializes in advanced lab equipment, including CVD systems, to help you create high-purity coatings for semiconductors, optics, and more. Contact our experts today to find the perfect solution for your deposition needs!

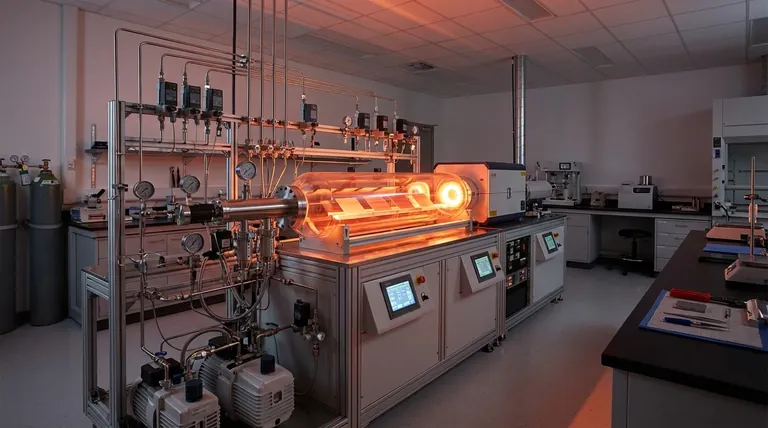

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings