In essence, Chemical Vapor Deposition (CVD) of metals is a manufacturing process that creates a thin, solid metal film on a surface by using a chemical reaction. Unlike physical methods that transfer solid material, CVD starts with volatile precursor gases containing the metal, which then react and decompose in a controlled chamber to deposit a high-purity metallic layer onto a substrate.

The critical distinction of CVD is that it is a chemical process, not a physical one. This allows it to "grow" a metal film atom-by-atom or layer-by-layer, enabling it to perfectly coat highly complex, three-dimensional surfaces where physical line-of-sight methods would fail.

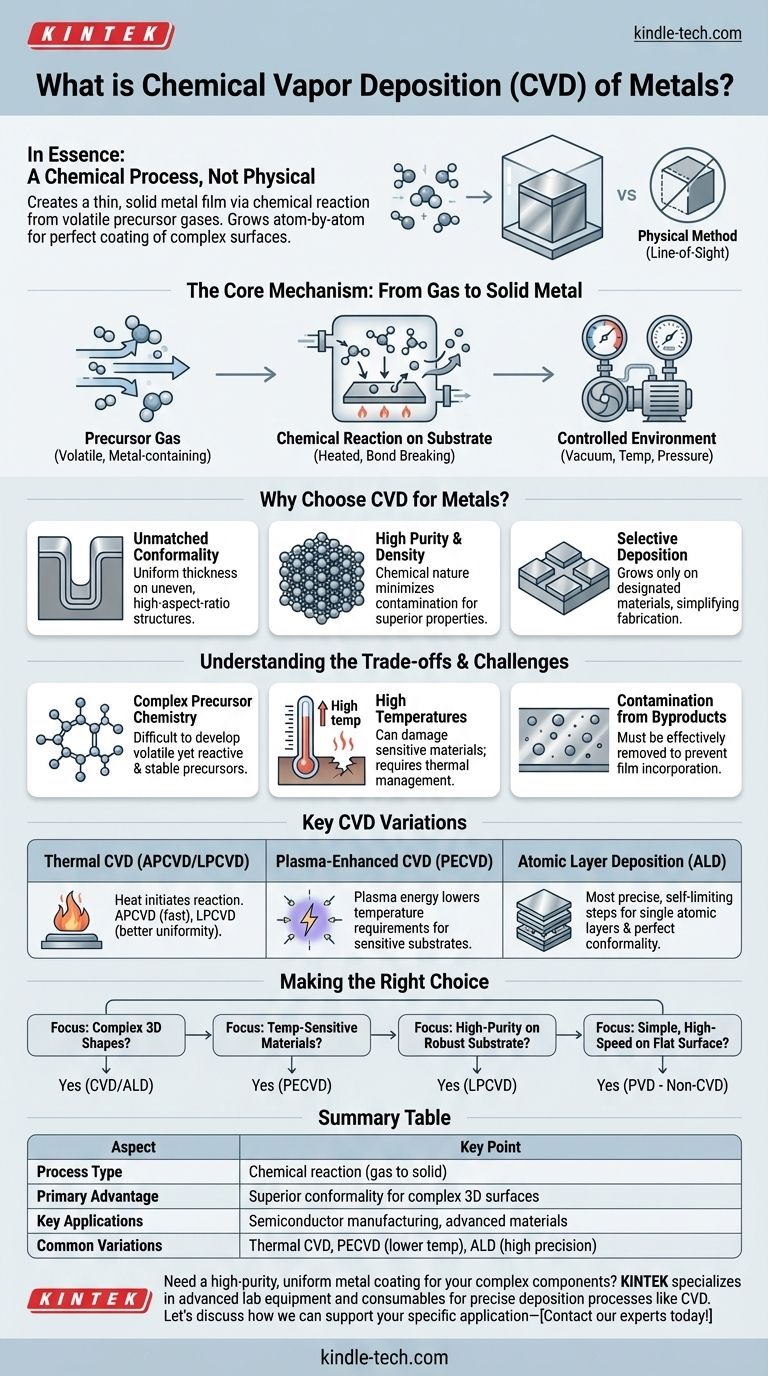

The Core Mechanism: From Gas to Solid Metal

Understanding CVD requires thinking about it not as spraying, but as a carefully controlled chemical reaction occurring directly on the target surface.

The Role of the Precursor Gas

The process begins with a specialized chemical compound called a precursor. This precursor is a gas or a liquid that can be easily vaporized.

Crucially, the precursor molecules contain the metal atoms that you want to deposit, but they are bonded to other elements that make the compound volatile at a manageable temperature.

The Chemical Reaction on the Substrate

Inside a vacuum chamber, the precursor gas is introduced and flows over a heated substrate. The thermal energy from the substrate provides the activation energy needed to break the chemical bonds within the precursor molecules.

When these bonds break, the desired metal atoms are released and deposit onto the surface, forming a solid film. The other elements are released as volatile byproducts, which are then pumped out of the chamber.

The Controlled Environment

The entire process takes place in a highly controlled environment. Chamber pressure and substrate temperature are the two most critical parameters, as they dictate the rate of reaction, the purity of the film, and its final crystalline structure.

Why Choose CVD for Metals?

While other methods like Physical Vapor Deposition (PVD) exist, CVD offers unique advantages for specific applications, particularly in semiconductor manufacturing and advanced materials.

Unmatched Conformality

Conformality is the ability of a film to maintain a uniform thickness as it coats an uneven surface with features like trenches or steps.

Because CVD precursors are gases, they can diffuse into and react within the most intricate and high-aspect-ratio structures. This results in an exceptionally uniform coating, a feat that is nearly impossible for line-of-sight PVD methods.

High Purity and Density

The chemical nature of the CVD process can produce films with extremely high purity and density. By carefully selecting precursors and managing process conditions, contamination can be minimized, leading to films with superior electrical and mechanical properties.

Selective Deposition

Under the right conditions, CVD reactions can be initiated only on specific materials. This allows for selective deposition, where the metal film grows on one part of a patterned substrate (e.g., on silicon but not on silicon dioxide), simplifying complex fabrication steps.

Understanding the Trade-offs and Challenges

No process is perfect. The strengths of CVD are balanced by significant technical challenges that must be managed.

Precursor Chemistry is Complex

The greatest challenge in metal CVD is often developing the right precursor. An ideal precursor must be volatile, thermally stable during delivery, yet reactive enough to decompose cleanly at the desired temperature. It should also be safe to handle and produce non-corrosive byproducts.

High Temperatures Can Be a Limitation

Traditional thermal CVD often requires very high substrate temperatures (hundreds of degrees Celsius) to drive the chemical reaction. This heat can damage or destroy temperature-sensitive substrates, such as polymers or previously fabricated electronic devices.

Contamination from Byproducts

The chemical byproducts released during deposition must be effectively removed from the chamber. If not, they can incorporate into the growing film as impurities or react with the substrate, compromising the final device's performance and reliability.

Key CVD Variations for Metal Deposition

To overcome the limitations of basic CVD, several specialized variations have been developed.

Thermal CVD (APCVD / LPCVD)

This is the most fundamental form, using only heat to initiate the reaction. It can be done at atmospheric pressure (APCVD) for high deposition rates or at low pressure (LPCVD) for better film uniformity and purity, which is more common for high-performance applications.

Plasma-Enhanced CVD (PECVD)

PECVD uses an electrical plasma to help break down the precursor gases. The energy from the plasma means the reaction can occur at much lower substrate temperatures, making it suitable for depositing films on temperature-sensitive materials.

Atomic Layer Deposition (ALD)

ALD is the most precise form of CVD. It separates the precursor reactions into a sequence of self-limiting, half-reaction steps. This process deposits a single atomic layer per cycle, offering unparalleled control over film thickness and perfect conformality, though at the cost of being a much slower process.

Making the Right Choice for Your Application

Selecting the correct deposition method depends entirely on the film properties you need and the constraints of your substrate.

- If your primary focus is coating complex 3D shapes or deep trenches: CVD, and specifically ALD for the highest precision, is the superior choice due to its unmatched conformality.

- If your primary focus is depositing on temperature-sensitive materials like plastics: PECVD is the necessary choice to avoid damaging the substrate with excessive heat.

- If your primary focus is high-purity, crystalline films on a robust substrate: LPCVD offers an excellent balance of quality and throughput for materials that can withstand the heat.

- If your primary focus is simple, high-speed coating on a flat surface: A non-CVD method like PVD (sputtering or evaporation) may be a more cost-effective solution.

Ultimately, mastering metal deposition requires understanding that CVD is a powerful tool of applied chemistry, not just a mechanical coating technique.

Summary Table:

| Aspect | Key Point |

|---|---|

| Process Type | Chemical reaction (gas to solid) |

| Primary Advantage | Superior conformality for complex 3D surfaces |

| Key Applications | Semiconductor manufacturing, advanced materials |

| Common Variations | Thermal CVD, PECVD (lower temp), ALD (high precision) |

Need a high-purity, uniform metal coating for your complex components?

KINTEK specializes in providing advanced lab equipment and consumables for precise deposition processes like CVD. Our solutions help laboratories in semiconductor and materials research achieve reliable, high-quality results.

Let's discuss how we can support your specific application—contact our experts today!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is the core function of an external gas generator in the CVD process? Optimize Coating Precision and Growth

- What is the importance of vacuum in thin film deposition? Control Film Purity and Performance

- What are the methods of chemical vapor deposition of graphene? A Guide to TCVD, PECVD, and More

- What is Thermally Activated Chemical Vapor Deposition (TACVD)? High-Purity Coating for Heat-Resistant Materials

- What metals are used in chemical vapour deposition? Achieve Superior, Conformal Metal Coatings

- Do CVD diamonds pass diamond tester? Yes, they are real diamonds.

- What role does a resistance heating furnace play in CVD tantalum coating? Master Thermal Precision in CVD Systems

- Why is the Chemical Vapor Deposition (CVD) process necessary for candle soot-templated silica? Enhancing Durability