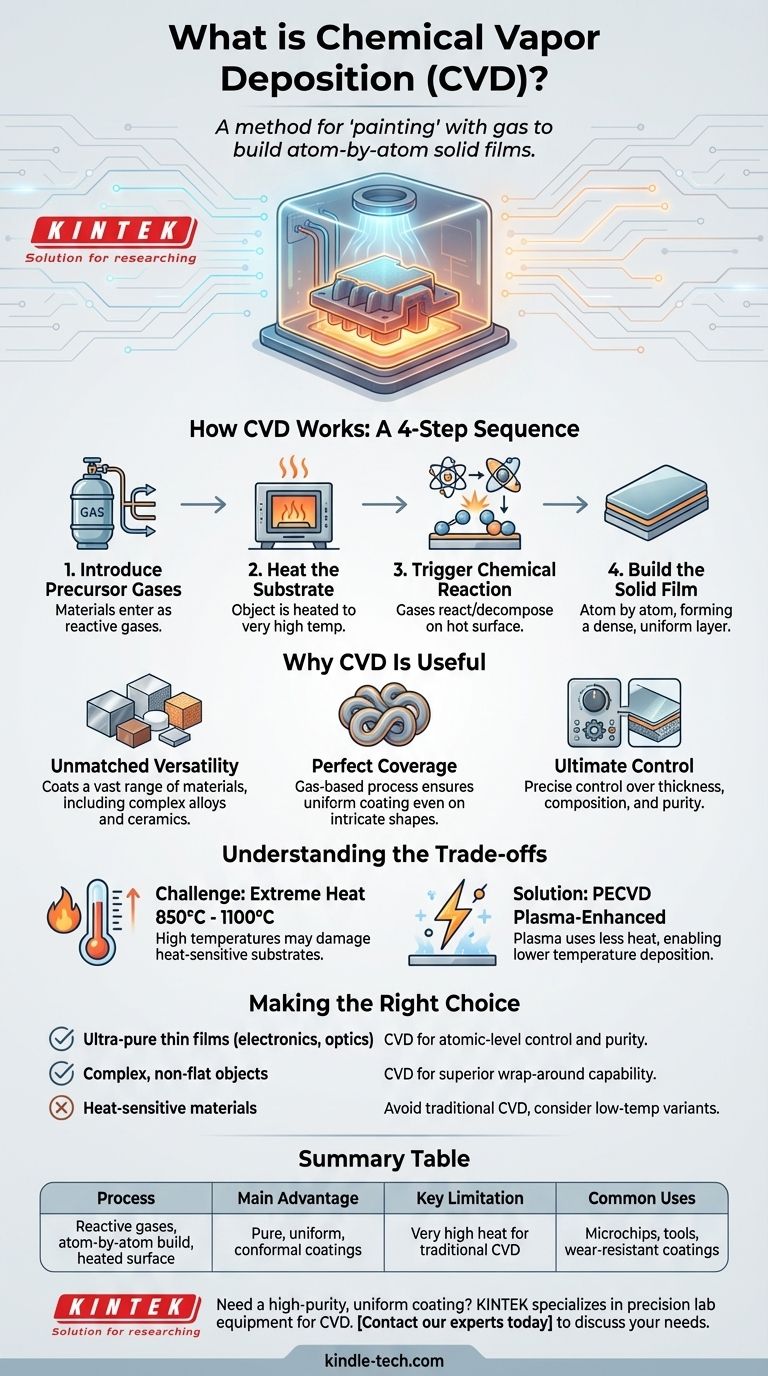

In simple terms, Chemical Vapor Deposition (CVD) is a method for "painting" with gas. Instead of using liquid paint, this process uses reactive gases in a high-temperature chamber to deposit an exceptionally thin and high-quality solid film onto a surface, atom by atom.

Chemical Vapor Deposition is fundamentally a manufacturing technique for building high-performance, ultra-thin solid layers on a surface (the substrate). It achieves this by introducing precursor gases into a chamber, which then react or decompose on the hot substrate to form the desired solid material.

How Does CVD Actually Work?

At its core, the CVD process can be understood as a three-step sequence involving gas, heat, and a chemical reaction. It is a precise and highly controlled method for building materials from the ground up.

Step 1: Introduce Gaseous Ingredients

The materials that will form the final solid film are first introduced into a reaction chamber as gases. These are often called precursor gases.

Step 2: Heat the Surface

The object to be coated, known as the substrate, is placed inside the chamber and heated to a very high temperature. This heat provides the energy needed for the next step to occur.

Step 3: Trigger a Chemical Reaction

When the precursor gases come into contact with the hot substrate, they undergo a chemical reaction or decomposition. This reaction causes the atoms to settle out of the gas and bond to the surface, forming a solid layer.

Step 4: Build the Solid Film

This process continues, building up the solid film one atomic layer at a time. The result is an exceptionally pure, dense, and uniform coating that perfectly conforms to the shape of the substrate.

Why Is CVD So Useful?

CVD is not just one technique but a versatile platform used to create critical components in industries from microelectronics to aerospace. Its advantages stem from the high degree of control it offers.

Unmatched Versatility

CVD can be used to deposit a vast range of materials. This includes metals, non-metals, complex alloys, and advanced ceramic compounds that are prized for their hardness and heat resistance.

Perfect Coverage on Complex Shapes

Because the coating is built from a gas, it can reach and uniformly cover every nook and cranny of a complex, three-dimensional object. This is known as a good wrap-around property, which is very difficult to achieve with liquid-based coating methods.

Ultimate Control and Purity

Technicians can precisely control the final film’s properties—such as its thickness, chemical composition, and crystal structure—by adjusting parameters like temperature, pressure, and gas mixture. This results in films of extremely high purity and density.

Understanding the Trade-offs

While powerful, the traditional CVD process has one significant limitation that determines where and how it can be used.

The Primary Challenge: Extreme Heat

Classic CVD processes require very high temperatures, often between 850°C and 1100°C. This intense heat means that the substrate material itself must be able to withstand it without melting, warping, or degrading.

Modern Solutions

To overcome this heat limitation, specialized versions of the process have been developed. Techniques like Plasma-Enhanced CVD (PECVD) use plasma instead of just heat to energize the gases, allowing deposition to occur at much lower temperatures.

Making the Right Choice for Your Goal

Understanding the core strengths of CVD helps clarify its ideal applications.

- If your primary focus is creating an ultra-pure, flawless thin film for electronics or optics: CVD is the gold standard due to its atomic-level control and high purity.

- If your primary focus is coating a complex, non-flat object with a uniform protective layer: CVD's "wrap-around" capability makes it a superior choice over line-of-sight methods.

- If your primary focus is working with heat-sensitive materials like plastics or certain alloys: You should avoid traditional CVD and instead investigate lower-temperature variants.

Ultimately, Chemical Vapor Deposition empowers engineers to construct materials with a precision that is simply not possible with other methods.

Summary Table:

| Key Aspect | Simple Explanation |

|---|---|

| Process | Using reactive gases to build a solid film atom by atom on a heated surface. |

| Main Advantage | Creates exceptionally pure, uniform, and conformal coatings on complex shapes. |

| Key Limitation | Traditional CVD requires very high temperatures, unsuitable for heat-sensitive materials. |

| Common Uses | Manufacturing microchips, cutting tools, and wear-resistant coatings. |

Need a high-purity, uniform coating for your components?

KINTEK specializes in precision lab equipment and consumables for advanced material deposition processes like CVD. Whether you are developing next-generation electronics, durable tool coatings, or specialized optics, our solutions help you achieve the ultimate control and purity your research demands.

Contact our experts today to discuss how we can support your laboratory's specific coating and thin-film needs.

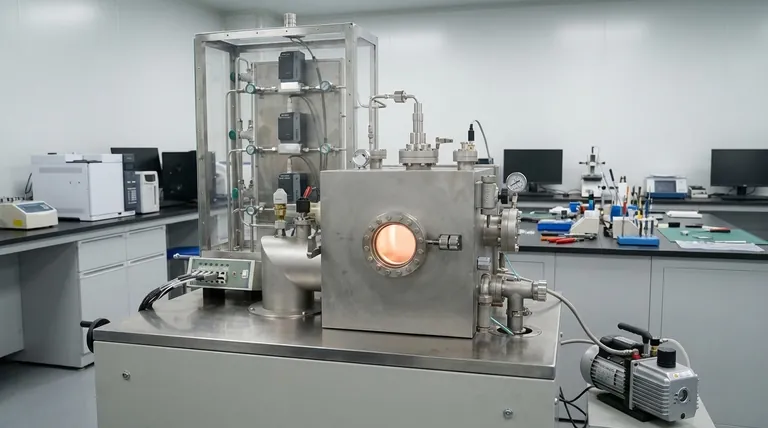

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application