At its core, Chemical Vapor Deposition (CVD) is a process for creating high-performance, ultra-thin films on a material's surface. It is not a paint or a simple layer; instead, it uses controlled chemical reactions between gases at high temperatures to "grow" a new, functional surface that is chemically bonded to the object it protects.

CVD is fundamentally a material engineering process. It allows you to give a bulk material entirely new surface properties—like extreme hardness or chemical resistance—by growing a new, high-purity layer on it atom by atom.

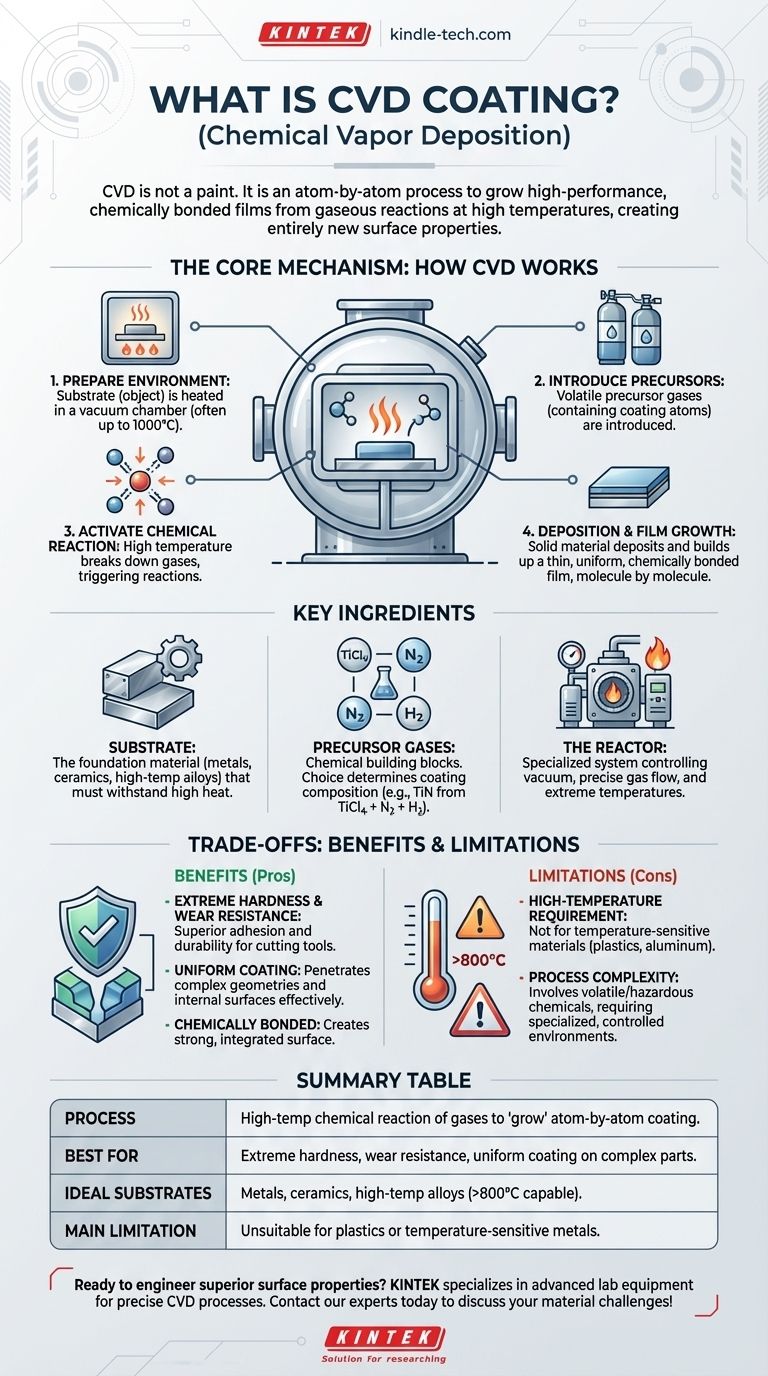

How Does CVD Work? The Core Mechanism

The CVD process transforms gaseous chemicals into a solid coating inside a controlled environment. While there are many variations, the fundamental principle remains consistent.

1. Preparing the Environment

The object to be coated, known as the substrate, is placed inside a vacuum chamber or reactor. The chamber is heated to a very high temperature, often up to 1000°C.

2. Introducing Precursor Gases

One or more volatile gases, called precursors, are introduced into the chamber. These gases contain the specific atoms needed to form the desired coating.

3. Activating the Chemical Reaction

The high temperature within the reactor provides the energy needed to break down the precursor gases. This triggers a series of chemical reactions.

4. Deposition and Film Growth

The reactions cause a solid material to form and deposit onto the hot substrate. This material builds up, molecule by molecule, creating a thin, dense, and highly uniform film that is chemically bonded to the substrate's surface.

The Key Ingredients of the CVD Process

Success in CVD depends on precisely controlling three main components: the substrate, the precursors, and the reactor environment.

The Substrate: The Foundation

The substrate is the material receiving the coating. Because of the high temperatures involved, substrates must be able to withstand the heat without deforming or melting. This typically includes metals, ceramics, and certain high-temperature alloys.

Precursor Gases: The Building Blocks

Precursors are the chemical source for the film. The choice of precursor directly determines the coating's composition.

For example, to create a Titanium Nitride (TiN) coating, gases like Titanium Tetrachloride (TiCl4), Nitrogen (N2), and Hydrogen (H2) are used. To form a Tin Oxide layer, tin organic compounds and oxygen might be used.

The Reactor: The Controlled Environment

The entire process takes place in a specialized CVD reactor. This system manages the vacuum, controls the precise flow of gases, and maintains the extremely high temperatures required for the reaction to occur safely and effectively.

Understanding the Trade-offs: Heat and Complexity

While powerful, CVD is not a universal solution. Its primary limitations stem directly from its core mechanism.

The High-Temperature Requirement

The need for temperatures often exceeding 800°C is the most significant constraint. This makes CVD unsuitable for temperature-sensitive materials like plastics, low-melting-point metals (like aluminum), or hardened steels that would lose their temper.

Process and Chemical Complexity

CVD involves volatile, and sometimes hazardous, precursor chemicals. The process must be conducted in highly specialized, controlled laboratory or industrial settings to manage risks and ensure a high-purity result. This makes it more complex and costly than some alternative coating methods.

Making the Right Choice for Your Goal

CVD is chosen when the performance of the surface is absolutely critical. Use these points to guide your decision.

- If your primary focus is extreme hardness and wear resistance: CVD is an exceptional choice, as the high-temperature process creates a chemically bonded film with superior adhesion and durability, ideal for cutting tools and wear parts.

- If you need a high-purity, uniform coating on complex shapes: The gaseous nature of CVD allows it to penetrate and coat intricate geometries and internal surfaces more effectively than line-of-sight processes.

- If your substrate is temperature-sensitive: You must look to alternative, lower-temperature processes like Physical Vapor Deposition (PVD), as standard CVD will likely damage or destroy your part.

Ultimately, choosing CVD is a decision to fundamentally re-engineer a material's surface for maximum performance.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | High-temperature chemical reaction of gases to 'grow' a coating atom by atom. |

| Best For | Extreme hardness, wear resistance, and uniform coating on complex geometries. |

| Ideal Substrates | Metals, ceramics, and high-temperature alloys that can withstand >800°C. |

| Main Limitation | Unsuitable for temperature-sensitive materials like plastics or aluminum. |

Ready to engineer superior surface properties for your components?

KINTEK specializes in advanced lab equipment and consumables for precise CVD processes. Our solutions help you achieve ultra-hard, durable coatings with exceptional adhesion.

Contact our experts today to discuss how CVD can solve your specific material challenges!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What is the effect of deposition temperature? Master Film Structure and Properties with Thermal Control

- What is an advantage of sputtering over older vacuum deposition? Superior Control for Complex Material Films

- What is the principle of CVD method? Mastering Atomic-Level Thin Film Deposition

- What are the problems with graphene production? The Key Challenges in Scaling Quality and Cost

- How does deposition occur in DC sputtering? Master the Kinetic Process for Superior Thin Films

- What is the sputtering system for deposition? Master Thin-Film Coating for Your Lab

- How does a CVD reactor work? Master the Science of High-Performance Thin Film Deposition

- How is pyrolysis oil produced? Turn Biomass into Bio-Crude with Fast Pyrolysis