At its core, a CVD diamond machine is a highly controlled reactor that grows real, high-purity diamonds from a gas. It uses a process called Chemical Vapor Deposition (CVD) to deposit carbon atoms onto a tiny diamond "seed" crystal. This systematically builds a larger, flawless diamond, layer by layer and atom by atom.

The machine itself is not a cutter or a polisher; it is an atomic-level construction chamber. Its primary purpose is to create an advanced, engineered material with properties like extreme hardness and thermal conductivity that are vital for high-tech industrial, optical, and electronic applications.

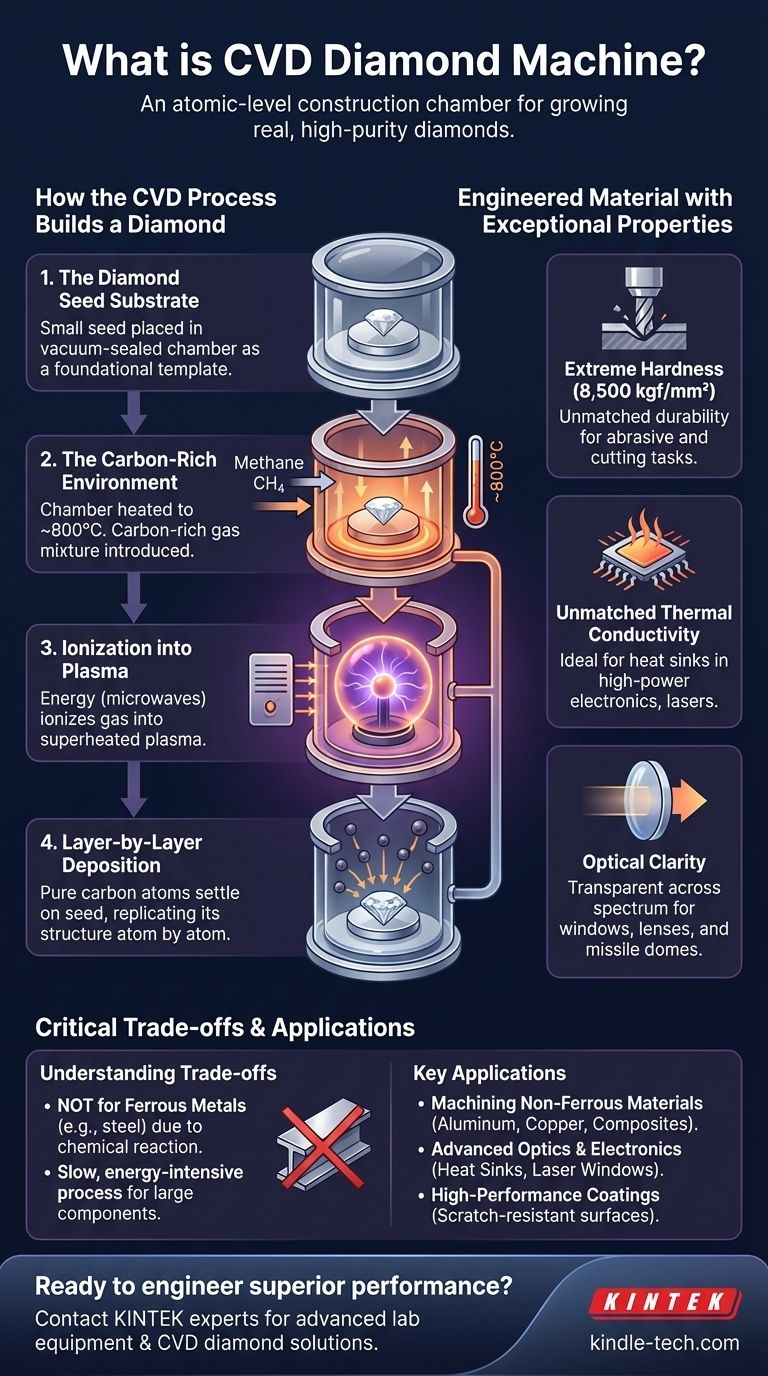

How the CVD Process Builds a Diamond

The machine's function is to create and maintain a perfect environment for diamond growth. The process unfolds in a precise sequence.

The Diamond Seed Substrate

The process begins by placing a small, thin slice of a pre-existing diamond, known as a seed, inside a vacuum-sealed chamber. This seed acts as the foundational template for the new crystal to grow upon.

The Carbon-Rich Environment

The chamber is then heated to approximately 800°C. A carefully controlled mixture of carbon-rich gases, typically including methane, is introduced. This gas mixture serves as the raw material for the new diamond.

Ionization into Plasma

Energy, often in the form of microwaves, is used to ionize the gases. This intense energy strips carbon atoms from their molecules, creating a glowing ball of superheated gas known as plasma.

Layer-by-Layer Deposition

Within the plasma, pure carbon atoms are freed. These atoms are drawn down to the relatively cooler surface of the diamond seed, where they bond to the crystal lattice. This process perfectly replicates the seed's structure, growing the diamond one atomic layer at a time.

An Engineered Material with Exceptional Properties

The diamond produced by a CVD machine is not a synthetic imitation; it is chemically and structurally identical to a mined diamond. This enables its use in applications that demand extreme performance.

Extreme Hardness and Durability

CVD diamond has a hardness of around 8,500 kgf/mm2 and an exceptionally low wear rate. This makes it one of the most durable materials known, ideal for abrasive and cutting tasks.

Unmatched Thermal Conductivity

As an exceptional thermal conductor, CVD diamond can rapidly pull heat away from sensitive components. This property is critical for its use as a heat sink in high-power electronics, lasers, and transistors.

Optical Clarity Across Wavelengths

The pure, uniform crystal structure makes CVD diamond transparent across a vast spectrum, from X-rays to microwaves. This makes it indispensable for creating robust windows and lenses for lasers, missile domes, and scientific equipment.

Understanding the Critical Trade-offs

While its properties are remarkable, CVD diamond is an engineered material with specific limitations that must be respected.

The Limitation with Ferrous Metals

CVD diamond tools are not suitable for machining steel or other iron-based metals. The high heat generated during cutting steel causes a chemical reaction between the carbon in the diamond and the iron, leading to rapid degradation and tool failure.

The Challenge of Scale and Cost

Growing large, defect-free diamond components is a slow and energy-intensive process. While perfect for small, critical parts, economically coating very large surface areas for consumer applications, such as non-stick cookware, remains a significant engineering hurdle.

Key Applications Across Industries

The ability to engineer diamond's properties has unlocked its use in fields far beyond jewelry.

Mechanical and Machining Tools

CVD diamond is used to create ultra-hard coatings and solid cutting tools for machining non-ferrous materials like aluminum, copper, and advanced composites. These tools can last 2 to 10 times longer than older Polycrystalline Diamond (PCD) technology.

Advanced Optics and Electronics

Its unique combination of thermal conductivity and broad transparency is essential for components in nuclear fusion reactors, airborne defense systems, and high-power laser optics.

High-Performance Coatings

A thin film of CVD diamond can be grown on other materials to impart its properties. This is used to create scratch-resistant, low-friction surfaces on everything from industrial valve rings to precision mechanical parts.

Making the Right Choice for Your Application

Selecting CVD diamond requires understanding its strengths and weaknesses relative to your goal.

- If your primary focus is machining non-ferrous materials: CVD diamond tools offer a significant upgrade in tool life, performance, and the quality of the finished surface.

- If your primary focus is thermal management or advanced optics: CVD diamond is a premier material for creating durable heat sinks and transparent windows that must perform in extreme environments.

- If your primary focus is machining steel or iron: You must choose an alternative cutting material, as the inherent chemical incompatibility will cause CVD diamond tools to fail quickly.

Ultimately, the CVD diamond machine allows us to transition from simply finding diamond to precisely engineering it to solve specific and demanding technical challenges.

Summary Table:

| Property | CVD Diamond Advantage |

|---|---|

| Hardness | Extreme durability (8,500 kgf/mm²) for cutting tools |

| Thermal Conductivity | Superior heat dissipation for electronics |

| Optical Clarity | Broad-spectrum transparency for lenses and windows |

| Primary Limitation | Not suitable for machining ferrous metals (e.g., steel) |

Ready to engineer superior performance into your lab or production line?

At KINTEK, we specialize in advanced lab equipment and consumables, including solutions for high-performance materials like CVD diamond. Our expertise can help you select the right tools to enhance durability, thermal management, and optical applications.

Contact our experts today via our Contact Form to discuss how KINTEK can support your specific laboratory and industrial needs.

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

People Also Ask

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies

- What are the primary advantages of the CVD method for growing diamonds? Engineering High-Purity Gems and Components

- What is the difference between MPCVD and HFCVD? Choose the Right CVD Method for Your Application

- How do lab-grown diamonds compare to natural diamonds? Uncover the Truth About Origin, Price, and Value

- Which lab grown diamond process is best? Focus on Quality, Not the Method