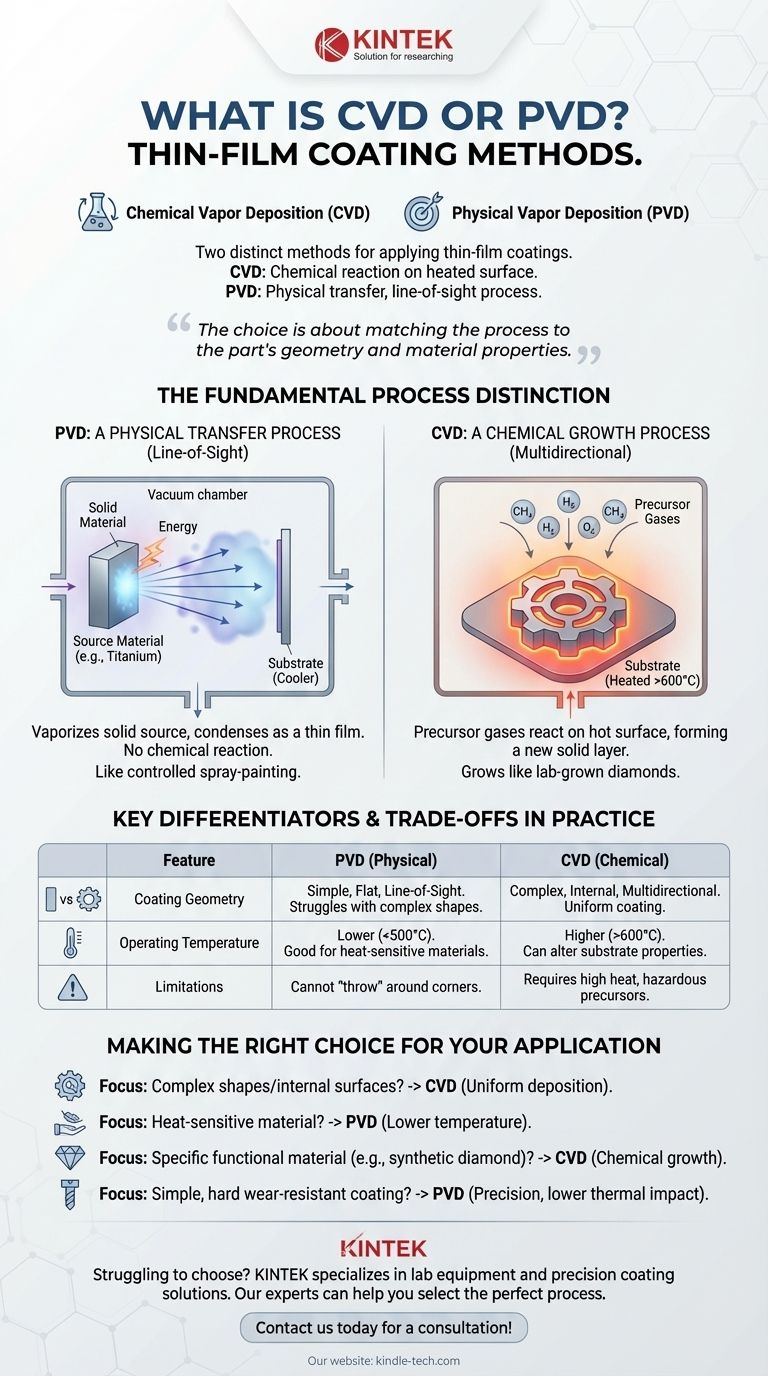

In material science and engineering, CVD and PVD are two distinct methods for applying thin-film coatings to a substrate. Chemical Vapor Deposition (CVD) uses precursor gases that chemically react on a heated surface to grow a new layer. In contrast, Physical Vapor Deposition (PVD) is a line-of-sight process that physically transfers material from a solid source to the substrate within a vacuum, much like a highly controlled spray-painting process.

The choice between PVD and CVD is not about which is "better," but about matching the process to the part's geometry and material properties. PVD is a lower-temperature, line-of-sight process ideal for simple shapes, while CVD is a higher-temperature chemical process that excels at uniformly coating complex geometries.

The Fundamental Process Distinction

At their core, PVD and CVD describe how a coating material arrives and adheres to a part's surface. The names themselves reveal the primary difference: one is physical, the other chemical.

PVD: A Physical Transfer Process

Physical Vapor Deposition is a "line-of-sight" process. Imagine a source material—a solid block of titanium, for example—being vaporized inside a vacuum chamber.

This vapor then travels in a straight line and condenses onto the cooler substrate, forming a thin, dense film. No chemical reaction occurs on the substrate; the material is simply moved from one place to another.

CVD: A Chemical Growth Process

Chemical Vapor Deposition is a process of controlled chemical reaction. A substrate is placed in a chamber and heated, while specific precursor gases are introduced.

These gases react on the hot surface, decomposing and forming a new solid material that "grows" as a film on the substrate. The creation of lab-grown diamonds, for instance, is a classic example of the CVD process, where carbon-containing gases build a diamond crystal layer by layer.

Key Differentiators in Practice

While the process distinction is clear, the practical consequences determine which method is right for a given application.

Coating Geometry and Uniformity

PVD is a line-of-sight impingement process. This makes it excellent for coating flat surfaces or simple tools, but it struggles to evenly coat complex shapes, sharp corners, or internal channels without elaborate fixtures to rotate the part.

CVD, by contrast, is multidirectional. Because it relies on a gas that can flow and diffuse, it can uniformly coat all exposed surfaces of a highly complex part, including internal bores and intricate features.

Operating Temperature

This is one of the most critical differentiators. CVD processes typically require very high temperatures (often >600°C) to drive the necessary chemical reactions on the substrate's surface.

PVD processes generally operate at much lower temperatures (often <500°C). This makes PVD suitable for coating materials that cannot withstand the high heat of CVD, such as tempered steels, aluminum alloys, or certain plastics.

Understanding the Trade-offs

Choosing a coating technology requires acknowledging the inherent limitations of each method. Being objective about these trade-offs is key to a successful outcome.

The Temperature Constraint of CVD

The high heat required for CVD can be a major limitation. It can alter the properties of the substrate material, such as changing the hardness of a heat-treated steel tool. This makes CVD unsuitable for many heat-sensitive components.

The Line-of-Sight Limitation of PVD

The primary drawback of PVD is its inability to "throw" coating around corners. If a surface is not directly in the line of sight of the vapor source, it will not be coated. This limits its use for parts with complex internal geometries.

Precursor and Byproduct Management

CVD often involves volatile, corrosive, or toxic precursor gases. The chemical reactions can also produce hazardous byproducts that must be safely managed and disposed of, adding complexity and cost to the operation.

Making the Right Choice for Your Application

Selecting the correct process depends entirely on your project's specific constraints and goals.

- If your primary focus is coating complex shapes or internal surfaces: CVD is the superior choice due to its non-line-of-sight, uniform deposition.

- If your primary focus is coating a heat-sensitive material: PVD is almost always the correct choice because of its significantly lower processing temperatures.

- If your primary focus is creating a specific functional material, like a synthetic diamond: CVD is the necessary method, as it builds the material through precise chemical reactions.

- If your primary focus is a simple, hard wear-resistant coating on a cutting tool: PVD is a highly effective and common industry standard for its precision and lower thermal impact.

Ultimately, understanding the fundamental difference between PVD's physical transfer and CVD's chemical growth is the key to selecting the right technology for your engineering goals.

Summary Table:

| Feature | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Process Type | Physical transfer (line-of-sight) | Chemical reaction (multidirectional) |

| Temperature | Lower (<500°C) | Higher (>600°C) |

| Coating Uniformity | Best for simple, flat surfaces | Excellent for complex geometries |

| Ideal For | Heat-sensitive materials, simple shapes | Complex parts, internal surfaces, material synthesis |

Struggling to choose between PVD and CVD for your project? KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision coating solutions. Our experts can help you select the perfect process to enhance your material's performance and durability. Contact us today for a personalized consultation!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What is plasma enhanced chemical vapour deposition process? Unlock Low-Temperature, High-Quality Thin Films

- What is the difference between CVD and PECVD? Choose the Right Thin-Film Deposition Method

- What is PECVD used for? Achieve Low-Temperature, High-Performance Thin Films

- What is plasma enhanced chemical vapor deposition? Achieve Low-Temperature, High-Quality Thin Films

- What is PECVD silicon deposition? Achieve Low-Temperature, High-Quality Thin Films