To be precise, dental ceramics are not a single substance but a class of advanced glass-ceramic materials. The most common types used for modern restorations are primarily composed of either leucite-based or lithium disilicate-based glass-ceramics, each engineered for specific clinical demands.

The core issue is not simply what dental ceramics are made of, but understanding that the choice of material represents a deliberate trade-off between aesthetic qualities and mechanical strength, tailored to the unique location and function of the tooth being restored.

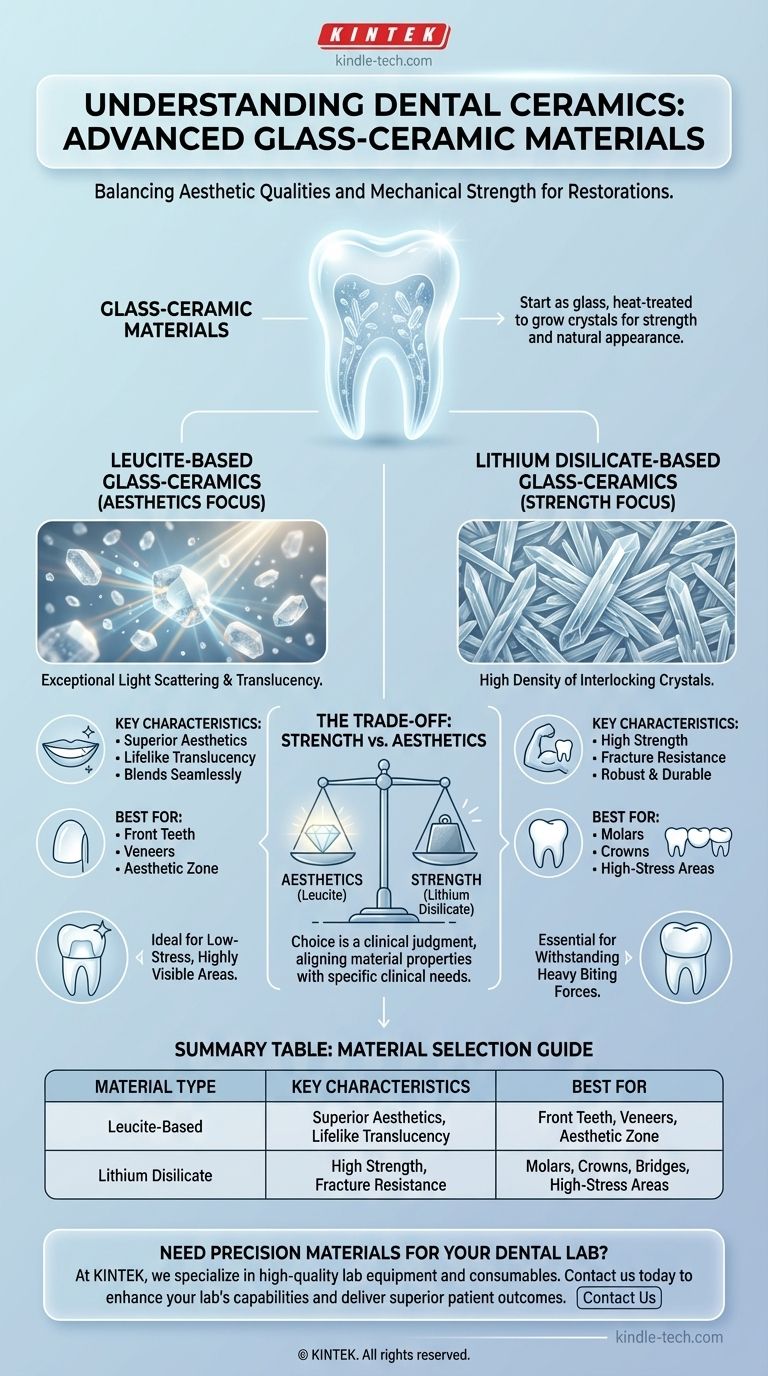

The Two Primary Classes of Dental Ceramics

Modern dental restorations rely heavily on glass-ceramics, which are materials that start as glass and are then heat-treated to grow microscopic crystals within their structure. This process gives them the strength and appearance needed to mimic natural teeth.

Leucite-Based Glass-Ceramics

Leucite-based ceramics are known for their exceptional aesthetic properties. The leucite crystals within the glass matrix are excellent at scattering light in a way that closely resembles natural tooth enamel.

This gives the material a vital, translucent appearance that is difficult to distinguish from a real tooth. It is often considered the gold standard for highly visible restorations where appearance is paramount.

Lithium Disilicate-Based Glass-Ceramics

Lithium disilicate is a significantly stronger and more durable material. It contains a higher density of interlocking, needle-like crystals that provide superior resistance to fracture.

While still offering excellent aesthetics, its primary advantage is its robustness. This makes it a versatile "workhorse" material suitable for a wide range of applications, including those that must withstand heavy biting forces.

Understanding the Trade-offs: Strength vs. Aesthetics

The decision to use one ceramic over another is a clinical judgment based on balancing the optical properties of the material against the mechanical forces it will need to endure.

The Priority of Aesthetics

For restorations in the "aesthetic zone"—the front teeth that are most visible when a person smiles—leucite-based ceramics are often the preferred choice.

Their ability to blend seamlessly with adjacent teeth makes them ideal for veneers and anterior crowns where the ultimate cosmetic result is the main goal.

The Demand for Strength

For posterior teeth like molars and premolars, chewing can exert tremendous force. In these high-stress situations, the superior fracture resistance of lithium disilicate is essential.

Using a less durable material in this area could lead to premature failure of the restoration. Lithium disilicate is also the material of choice for multi-tooth bridges that require greater structural integrity.

Making the Right Choice for Your Restoration

The selection of a dental ceramic is a precise decision based on the restoration's functional and cosmetic requirements.

- If your primary focus is maximum aesthetics in a low-stress area (like a front tooth veneer): Leucite-based ceramics provide the most lifelike translucency and are often the superior choice.

- If your primary focus is a durable, long-lasting restoration that can withstand high biting forces (like a molar crown): Lithium disilicate offers a reliable combination of high strength and very good aesthetics.

Ultimately, choosing the right material is about aligning its inherent properties with the specific clinical needs of the patient.

Summary Table:

| Material Type | Key Characteristics | Best For |

|---|---|---|

| Leucite-Based | Superior aesthetics, lifelike translucency | Front teeth, veneers, aesthetic zone |

| Lithium Disilicate | High strength, fracture resistance | Molars, crowns, bridges, high-stress areas |

Need precision materials for your dental lab? At KINTEK, we specialize in high-quality lab equipment and consumables tailored for dental professionals. Whether you're crafting lifelike leucite restorations or durable lithium disilicate crowns, our products ensure reliability and excellence. Contact us today to enhance your lab's capabilities and deliver superior patient outcomes!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations

- What is the effect of zirconia sintering temperature? Master the Key to Strength and Stability

- What are the white spots on zirconia after sintering? A Guide to Diagnosing and Preventing Defects