At their core, dental ceramics are a class of advanced, non-metallic inorganic materials used to restore or replace missing tooth structure. They are chosen for their exceptional ability to mimic the appearance of natural teeth, their durability, and their high biocompatibility. While some ceramic-based compounds are used as cements, the term primarily refers to materials like lithium disilicate and zirconia used to fabricate crowns, veneers, and bridges.

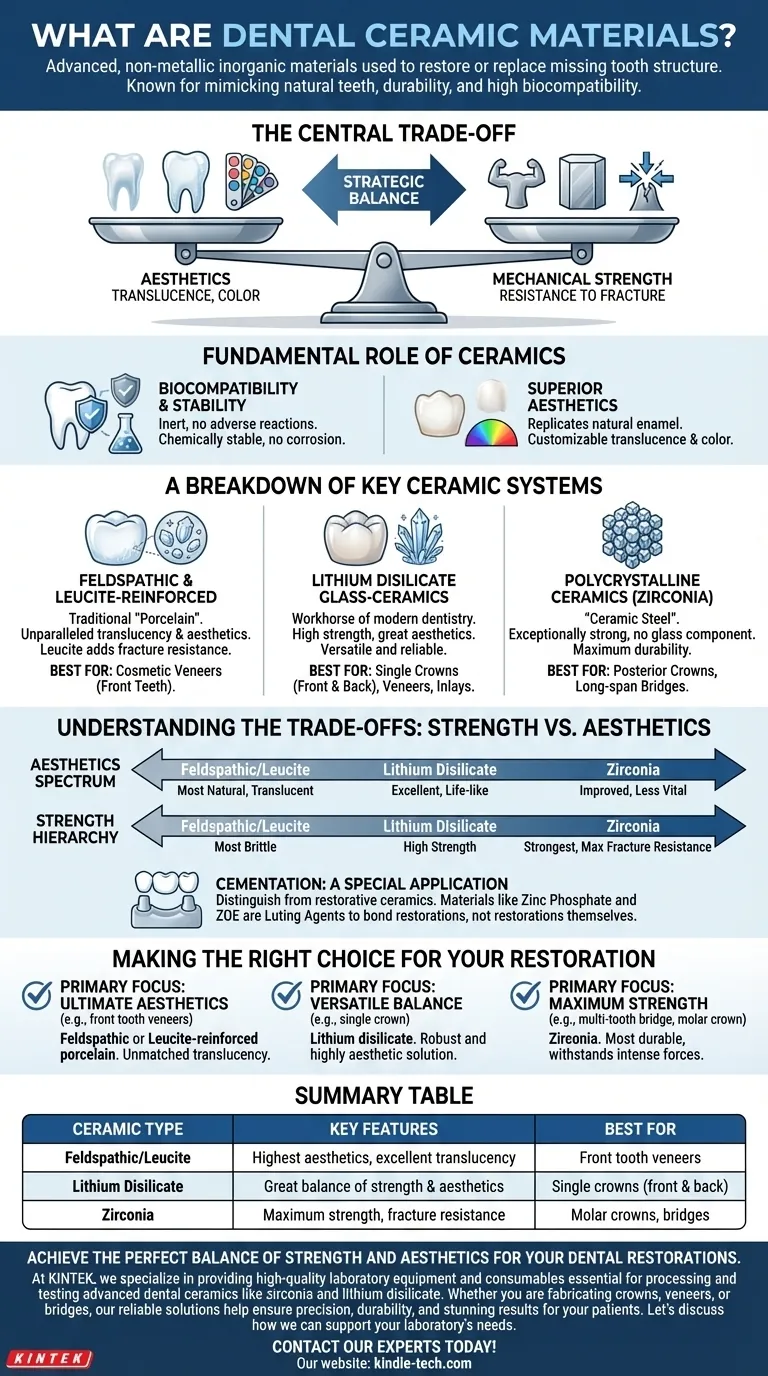

The central concept to grasp is that "dental ceramic" is not a single substance, but a family of materials. The choice of a specific ceramic always involves a strategic trade-off between aesthetic qualities (translucence, color) and mechanical strength (resistance to fracture).

The Fundamental Role of Ceramics in Dentistry

Modern dentistry relies on ceramics because they solve several critical challenges at once. They offer a unique combination of properties that metals and plastics cannot match.

Biocompatibility and Stability

Ceramics are highly biocompatible, meaning they are inert and do not cause adverse reactions with the tissues in your mouth. They are also chemically stable and do not corrode or degrade over time like some metal alloys can.

Superior Aesthetics

The primary advantage of ceramics is their ability to replicate the optical properties of natural enamel and dentin. Their translucence, color, and texture can be customized to create restorations that are virtually indistinguishable from real teeth.

A Breakdown of Key Ceramic Systems

The evolution of dental ceramics has produced several distinct categories, each with its own ideal use case. They are generally classified as glass-ceramics or polycrystalline ceramics.

Feldspathic and Leucite-Reinforced Ceramics

These are the most traditional dental ceramics, often referred to simply as "porcelain." They are composed of a glass matrix that gives them unparalleled translucency and aesthetic potential.

Leucite-reinforced ceramics add leucite crystals to this glass matrix, which helps increase fracture resistance without significantly compromising their beauty. These materials are often the top choice for cosmetic veneers on front teeth.

Lithium Disilicate Glass-Ceramics

Lithium disilicate is a true workhorse of modern restorative dentistry. This material contains a high concentration of needle-like lithium disilicate crystals, giving it significantly more strength than traditional porcelains.

It offers an excellent balance of high strength and great aesthetics, making it a versatile and reliable choice for single crowns on both front and back teeth, as well as veneers and inlays.

Polycrystalline Ceramics (Zirconia)

Zirconia is in a class of its own. It is a polycrystalline ceramic, meaning it has no glass component and is composed of densely packed crystals. This structure makes it exceptionally strong and resistant to fracture.

Often called "ceramic steel," zirconia is the strongest of all dental ceramics. It is the ideal material for situations that demand maximum durability, such as posterior crowns that endure heavy chewing forces or long-span dental bridges.

Understanding the Trade-offs: Strength vs. Aesthetics

Choosing the right ceramic is a clinical decision based on balancing competing priorities. No single material is perfect for every situation.

The Aesthetics Spectrum

Feldspathic porcelain sits at the highest end of the aesthetic spectrum, offering the most natural-looking results. Lithium disilicate provides excellent, life-like aesthetics that are suitable for almost any area of the mouth.

Early forms of zirconia were very opaque and less aesthetic, but modern formulations have improved translucency, making them a more viable option for visible areas. However, they still generally do not match the vitality of glass-ceramics.

The Strength Hierarchy

The strength of these materials exists on a clear hierarchy. Feldspathic porcelain is the most brittle, while zirconia is by far the strongest.

This is the primary factor when choosing a material for a molar crown or a bridge. The forces in the back of the mouth require the fracture resistance that only a high-strength material like zirconia or lithium disilicate can provide.

Cementation: A Special Application

It is important to distinguish restorative ceramics from ceramic-based cements. Materials like zinc phosphate and zinc oxide-eugenol (ZOE) are cements used to bond crowns and bridges to the tooth structure. While technically containing ceramic components, they serve a different function as a luting agent, not as the restoration itself.

Making the Right Choice for Your Restoration

The selection of a dental ceramic is tailored to the specific clinical need, location in the mouth, and desired outcome.

- If your primary focus is ultimate aesthetics (e.g., front tooth veneers): A feldspathic or leucite-reinforced porcelain is often the top choice for its unmatched translucency.

- If your primary focus is a versatile balance of strength and beauty (e.g., a single crown): Lithium disilicate provides a robust and highly aesthetic solution for nearly any tooth.

- If your primary focus is maximum strength (e.g., a multi-tooth bridge or molar crown): Zirconia is the most durable and reliable option to withstand intense functional forces.

Understanding this balance empowers you and your clinician to select the material that ensures a durable, beautiful, and long-lasting result.

Summary Table:

| Ceramic Type | Key Features | Best For |

|---|---|---|

| Feldspathic/Leucite | Highest aesthetics, excellent translucency | Front tooth veneers |

| Lithium Disilicate | Great balance of strength & aesthetics | Single crowns (front & back) |

| Zirconia | Maximum strength, fracture resistance | Molar crowns, bridges |

Achieve the perfect balance of strength and aesthetics for your dental restorations.

At KINTEK, we specialize in providing high-quality laboratory equipment and consumables essential for processing and testing advanced dental ceramics like zirconia and lithium disilicate. Whether you are fabricating crowns, veneers, or bridges, our reliable solutions help ensure precision, durability, and stunning results for your patients.

Let’s discuss how we can support your laboratory's needs. Contact our experts today!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

- Boron Nitride (BN) Ceramic Tube

- Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

- High-Purity Titanium Foil and Sheet for Industrial Applications

People Also Ask

- What is the sintering temperature of zirconium? A Guide to the 1400°C-1600°C Range for Dental Labs

- What is one of the newest applications for dental ceramics? Monolithic Zirconia for Full-Arch Bridges

- What makes zirconia translucent? The Science Behind Modern Dental Aesthetics

- What are the white spots on zirconia after sintering? A Guide to Diagnosing and Preventing Defects

- Can you change the color of zirconia crowns? Understanding the Permanent Nature of Zirconia