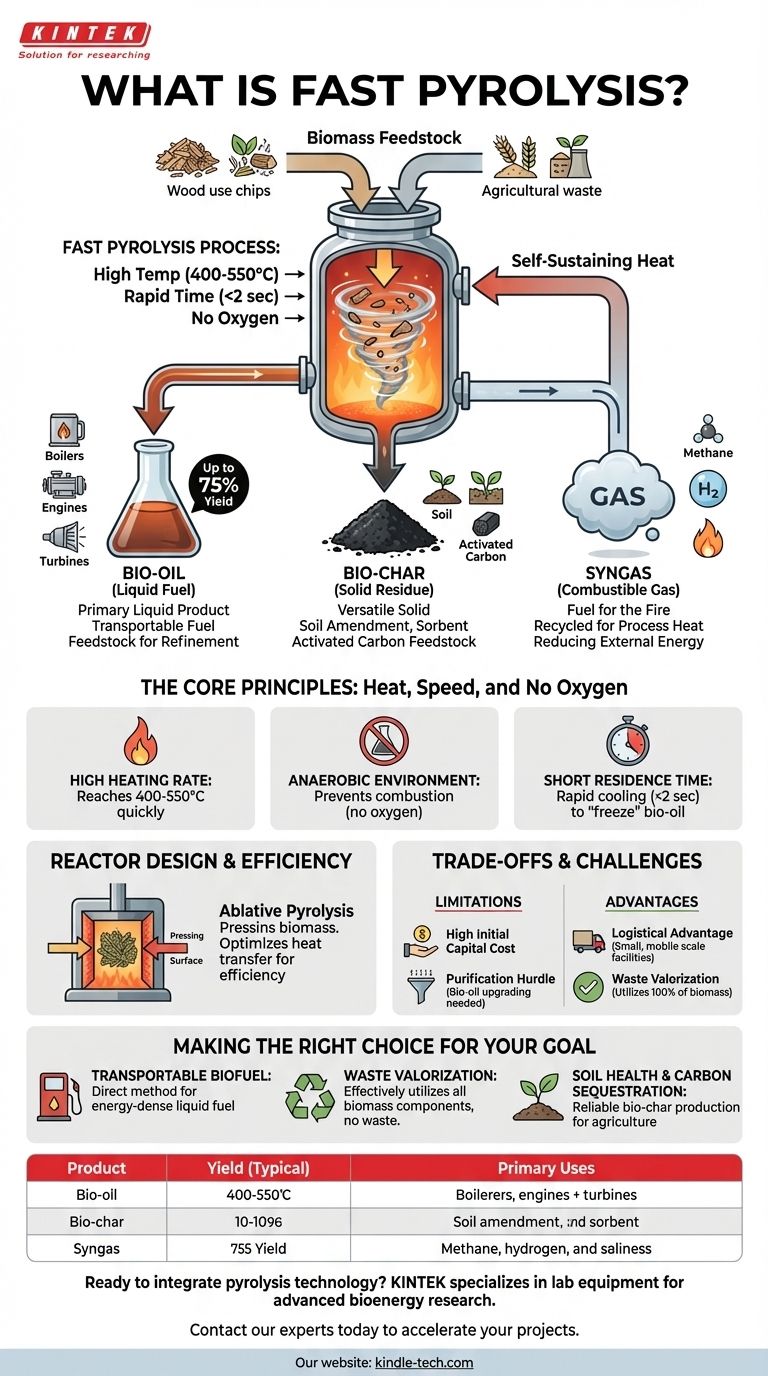

In simple terms, fast pyrolysis is a high-temperature process that rapidly breaks down organic material, like wood or agricultural waste, in the absence of oxygen. It operates at temperatures between 400-550°C with an extremely short reaction time of less than two seconds. This process transforms solid biomass into three main products: a liquid called bio-oil, a solid known as bio-char, and a combustible gas mixture called syngas.

The core value of fast pyrolysis lies in its ability to convert bulky, low-density biomass into a dense, transportable liquid fuel (bio-oil). This solves a major logistical challenge in the bioenergy sector by making it easier to store and move energy derived from renewable resources.

How Fast Pyrolysis Works: The Core Principles

Fast pyrolysis is fundamentally a thermal decomposition process, engineered for a specific outcome. The efficiency and product yields are dictated by three critical parameters: heat, speed, and the absence of oxygen.

The Critical Ingredients: Heat, Speed, and No Oxygen

The process requires a high heating rate to bring the biomass to a target temperature of 400-550°C.

This intense heat is applied in an anaerobic (oxygen-free) environment to prevent the biomass from simply burning (combustion).

Critically, the resulting vapors are rapidly cooled after a very short residence time (less than 2 seconds). This quick cooling "freezes" the chemical reactions, condensing the vapors into the liquid bio-oil before they can break down further into less valuable gases.

A Self-Sustaining Process

One of the most elegant aspects of fast pyrolysis is its potential for energy self-sufficiency.

The process produces flammable syngas (containing methane, hydrogen, and carbon monoxide) as a co-product. This gas can be captured and burned to provide the heat required for the reactor, significantly reducing the need for external energy inputs.

The Role of Reactor Design

Different reactor technologies exist to optimize the process. For instance, ablative pyrolysis reactors use pressure to press biomass against a hot surface.

This design transfers heat very efficiently and can reduce the total amount of external energy needed to run the system, representing a key area of process innovation.

Deconstructing the Outputs: More Than Just Oil

The genius of fast pyrolysis is that it converts virtually 100% of the initial biomass into useful products, leaving no waste behind.

Bio-Oil: The Primary Liquid Product

Bio-oil is the main output, often comprising up to 75% of the product yield by weight. It is a dense, dark liquid that can be used as a fuel for boilers, engines, and turbines.

It can also be further refined to produce transportation fuels or serve as a source of valuable chemical commodities.

Bio-char: A Versatile Solid

The solid residue, known as bio-char, is essentially a form of charcoal.

It has significant value as a soil amendment to improve fertility and water retention. It can also be used as a sorbent for environmental cleanup or as a feedstock to produce high-grade activated carbon.

Syngas: Fuel for the Fire

The non-condensable gases, or syngas, are the third product stream. As mentioned, their primary role is often to be recycled back into the system to provide process heat.

Understanding the Trade-offs and Challenges

While powerful, fast pyrolysis is not without its complexities. A clear-eyed view of its limitations is necessary for any serious evaluation.

The Cost of Entry

Fast pyrolysis facilities require specialized reactors and control systems, leading to a high initial capital cost. This represents a significant barrier to wider adoption, particularly for smaller operations.

The Purification Hurdle

The raw bio-oil produced is acidic, contains water, and is chemically complex. It often requires separation and upgrading before it can be used in conventional engines or refineries. This post-processing step adds cost and complexity.

The Logistical Advantage

Despite the costs, fast pyrolysis offers a key logistical benefit. Facilities can be built on a relatively small, mobile scale.

This allows for the production of bio-oil close to the source of the biomass, converting a bulky solid into a dense liquid that is much cheaper to transport to a central upgrading facility.

Making the Right Choice for Your Goal

Fast pyrolysis is a strategic tool in the bioenergy and circular economy landscape. Its suitability depends entirely on your specific objective.

- If your primary focus is creating a transportable biofuel: Fast pyrolysis is the most direct method for converting low-density, dispersed biomass into an energy-dense liquid fuel.

- If your primary focus is waste valorization: This process is ideal because it effectively utilizes all components of the biomass feedstock, creating multiple valuable products with no waste.

- If your primary focus is soil health and carbon sequestration: The reliable production of bio-char as a co-product makes fast pyrolysis a key technology for agricultural and environmental applications.

Ultimately, fast pyrolysis provides a rapid and efficient pathway to unlock the chemical energy stored within biomass.

Summary Table:

| Product | Yield (Typical) | Primary Uses |

|---|---|---|

| Bio-oil | Up to 75% | Liquid fuel for boilers/engines; feedstock for refinement |

| Bio-char | Varies | Soil amendment, sorbent, activated carbon feedstock |

| Syngas | Varies | Process heat for the reactor, reducing external energy needs |

Ready to integrate pyrolysis technology into your laboratory or pilot plant?

KINTEK specializes in supplying robust lab equipment and consumables for advanced bioenergy research. Whether you are developing new reactor designs, analyzing bio-oil composition, or studying bio-char properties, our precise and reliable tools are designed to support your innovation.

Contact our experts today to discuss how KINTEK's solutions can accelerate your biomass conversion projects and help you achieve your sustainability goals.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What is the primary function and principle of autoclaving? Master Lab Sterilization with High-Pressure Steam

- What role does an autoclave play in the acid treatment for microalgae disruption? Unlock High-Yield Cell Pretreatment

- What are the advantages of using an autoclave equipped with a stirring device for molten salt testing? Dynamic Accuracy

- What is the primary function of a laboratory autoclave in the pre-treatment of medical plastic waste for liquid fuel?

- What role do laboratory autoclaves play in pectin extraction? Optimize Prebiotic Yield from Citrus and Apple Biomass