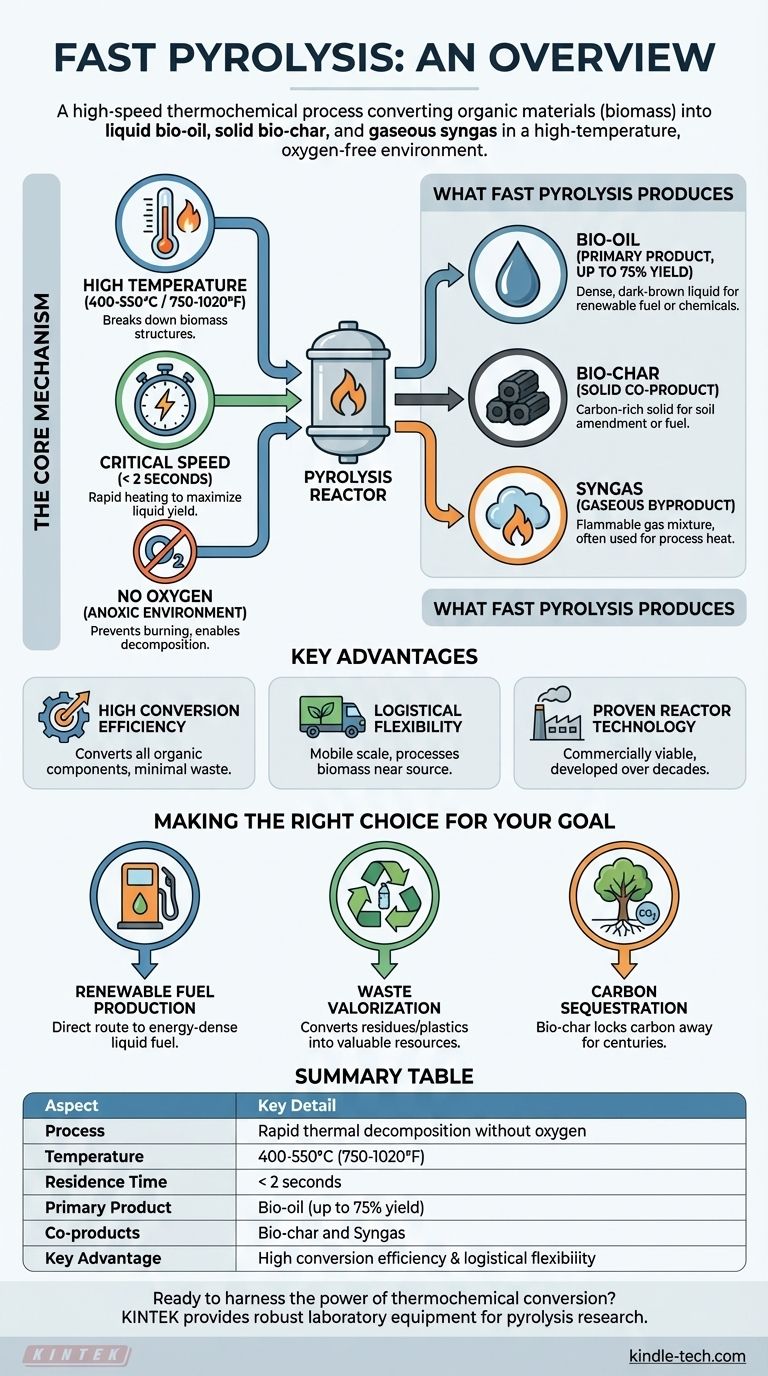

In essence, fast pyrolysis is a high-speed thermochemical process that rapidly converts organic materials, such as biomass, into a liquid fuel known as bio-oil. The entire conversion happens at high temperatures in an environment completely devoid of oxygen, ensuring the material breaks down rather than burns. It also produces two valuable co-products: a solid called bio-char and a flammable gas mixture called syngas.

The core principle of fast pyrolysis is its speed. By rapidly heating biomass in under two seconds, the process intentionally maximizes the yield of liquid bio-oil, preventing it from further degrading into less valuable gases and solids.

The Core Mechanism: Heat, Speed, and No Oxygen

To understand fast pyrolysis, it's essential to grasp its three defining conditions. Each element is precisely controlled to favor the production of liquid oil over other potential products.

The Role of High Temperature

Fast pyrolysis operates at temperatures between 400-550°C (750-1020°F). This intense heat provides the energy needed to break down the complex and rigid structures of biomass, such as cellulose and lignin, into smaller, volatile vapors.

The Critical Need for Speed

The process is defined by its extremely short residence time—the vapors remain in the hot reactor for less than two seconds. This rapid heating and short duration are crucial for capturing the intermediate liquid products before they can break down further into stable, low-value gases.

The Absence of Oxygen

The entire process occurs in an oxygen-free (anoxic) environment. This is the fundamental difference between pyrolysis and combustion. Without oxygen, the biomass cannot burn; it can only thermally decompose, allowing its chemical components to be re-formed into new products.

What Fast Pyrolysis Produces

The output of fast pyrolysis is not a single substance but a portfolio of useful products. The primary goal is typically the liquid, but the solid and gas fractions are integral to the process's overall efficiency and value.

Bio-oil: The Primary Liquid Product

This is the main product, often accounting for up to 75% of the initial biomass weight. Bio-oil is a dense, dark-brown liquid that can be used as a renewable fuel for heating or upgraded into transportation fuels and other valuable chemicals.

Bio-char: The Solid Co-product

This stable, carbon-rich solid is similar to charcoal. Bio-char can be burned as a fuel, but it is increasingly valued as a soil amendment to improve fertility or as a precursor for producing activated carbon.

Syngas: The Gaseous Byproduct

The process also creates a mixture of flammable gases, including methane, hydrogen, and carbon monoxide. This syngas is almost always recycled and burned on-site to provide the heat required for the reactor, making the entire process more energy-efficient and self-sustaining.

Understanding the Key Advantages

Fast pyrolysis has become a viable technology because it addresses several key logistical and efficiency challenges associated with using biomass for energy.

High Conversion Efficiency

Unlike some biological processes, fast pyrolysis can convert all organic components of the biomass feedstock. This whole-biomass utilization means very little of the initial material goes to waste.

Logistical Flexibility

Biomass is often bulky and expensive to transport. Pyrolysis facilities can be built on a relatively small, mobile scale to process biomass near its source, converting it into energy-dense bio-oil that is much cheaper to transport to a central refinery.

Proven Reactor Technology

While still evolving, fast pyrolysis reactors are relatively simple and have reached a level of commercial production. The technology has been developed and refined over several decades, establishing it as a feasible pathway for renewable fuel.

Making the Right Choice for Your Goal

Fast pyrolysis is not a single solution but a versatile platform technology. Its application depends entirely on your end goal.

- If your primary focus is renewable fuel production: Fast pyrolysis provides one of the most direct routes for converting solid, low-density biomass into a liquid, energy-dense fuel.

- If your primary focus is waste valorization: The technology is highly effective for converting agricultural residues or even certain plastic wastes into valuable fuels and chemical feedstocks.

- If your primary focus is carbon sequestration: The bio-char co-product is a highly stable form of carbon that, when used as a soil amendment, can lock carbon away for centuries.

Ultimately, fast pyrolysis stands as a powerful and rapid technology for transforming low-value biomass into high-value energy and material resources.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process | Rapid thermal decomposition without oxygen |

| Temperature | 400-550°C (750-1020°F) |

| Residence Time | < 2 seconds |

| Primary Product | Bio-oil (up to 75% yield) |

| Co-products | Bio-char and Syngas |

| Key Advantage | High conversion efficiency & logistical flexibility |

Ready to harness the power of thermochemical conversion?

KINTEK specializes in providing robust and reliable laboratory equipment for pyrolysis research and process development. Whether you are exploring bio-oil production, waste valorization, or carbon sequestration, our reactors and analytical tools are designed to deliver precise, reproducible results.

Contact us today using the form below to discuss how our solutions can accelerate your biomass conversion projects. Let's turn your renewable energy goals into reality.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time