At its core, golden PVD is not a type of gold plating. It is a high-performance surface coating created through a process called Physical Vapor Deposition (PVD). This technique deposits a very thin, extremely hard ceramic material—most often Titanium Nitride—onto a surface in a vacuum, which has a natural gold color and provides exceptional durability.

The critical takeaway is that golden PVD uses advanced material science to achieve the look of gold while delivering far superior scratch resistance, wear, and corrosion protection than traditional gold plating. It is a finish engineered for longevity, not for precious metal content.

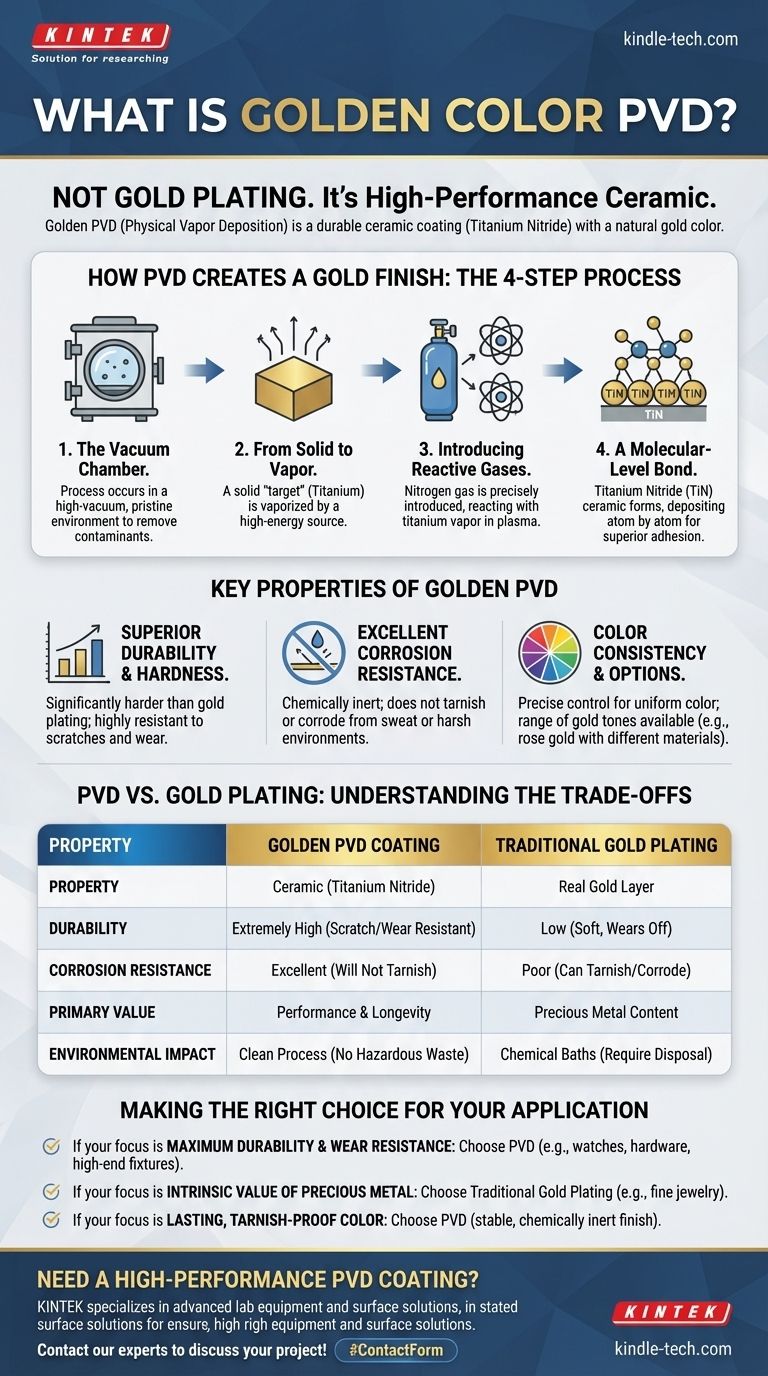

How the PVD Process Creates a Gold Finish

The term Physical Vapor Deposition describes the method, not the material. The process transforms a solid material into a vapor, which then condenses onto a target object as a thin, tightly bonded film.

The Vacuum Chamber Environment

The entire process takes place in a high-vacuum chamber. The parts to be coated are placed inside, and the air is removed to create a pristine environment, free from contaminants that could interfere with the coating's adhesion.

From Solid to Vapor

A solid block of the coating material, known as the "target," is vaporized using a high-energy source. For a classic gold color, this target is typically made of titanium.

Introducing Reactive Gases

To create the final compound, a reactive gas—in this case, nitrogen—is precisely introduced into the chamber. The vaporized titanium atoms react with the nitrogen atoms in a plasma environment.

A Molecular-Level Bond

This reaction forms a new ceramic compound, Titanium Nitride (TiN), which deposits atom by atom onto the surface of the object. This isn't a layer of paint; it's a film that is molecularly bonded to the substrate, making it incredibly difficult to chip or flake off. The inherent, stable color of Titanium Nitride is a brilliant gold.

Key Properties of Golden PVD

The reason PVD is chosen for so many high-performance applications, from luxury watches to industrial drill bits, is due to the outstanding properties of the resulting finish.

Superior Durability and Hardness

The ceramic PVD coating is significantly harder than traditional gold plating and even the base substrate material (like stainless steel). This makes it highly resistant to scratches, abrasion, and daily wear.

Excellent Corrosion Resistance

PVD coatings are chemically inert. This means a golden PVD finish will not tarnish or corrode when exposed to sweat, saltwater, or other harsh environmental factors, unlike many traditional metal finishes.

Color Consistency and Options

The PVD process allows for extremely precise control over the coating's composition and thickness. This results in a perfectly uniform and consistent color across the entire surface and from one batch to the next. By adjusting the materials and gases (e.g., using Zirconium Nitride), a range of gold tones, from pale yellow to rich rose gold, can be achieved.

Understanding the Trade-offs: PVD vs. Gold Plating

Choosing between PVD and traditional gold plating requires understanding their fundamental differences.

The Material Itself

PVD is a gold-colored ceramic. It contains no actual gold. Its value comes from its performance and durability.

Gold plating is a thin layer of real gold deposited onto a surface through an electrochemical process (electroplating). Its value is tied to its precious metal content.

Durability and Longevity

In any durability test—scratch, wear, or corrosion—PVD is vastly superior. A gold-plated item will eventually show wear as the soft gold layer rubs off, especially on high-contact points. A PVD coating is designed to last for years, even under demanding conditions.

The Environmental Impact

Modern PVD processes are environmentally clean, producing no hazardous waste. Traditional electroplating, by contrast, involves baths of chemical solutions that require careful disposal.

Making the Right Choice for Your Application

Selecting the correct finish depends entirely on your primary goal for the product.

- If your primary focus is maximum durability and wear resistance: PVD is the definitive choice for items like watches, architectural hardware, and high-end fixtures that must withstand daily use.

- If your primary focus is the intrinsic value of precious metal: Traditional gold plating is the only option that uses a layer of real gold, which may be essential for the perceived value of fine jewelry.

- If your primary focus is a lasting, tarnish-proof color: PVD provides a stable, chemically inert finish that will not fade or discolor over time.

Ultimately, choosing golden PVD is a decision to prioritize modern material science for a finish that is engineered to endure.

Summary Table:

| Property | Golden PVD Coating | Traditional Gold Plating |

|---|---|---|

| Material | Ceramic (Titanium Nitride) | Real Gold Layer |

| Durability | Extremely High (Scratch/Wear Resistant) | Low (Soft, Wears Off) |

| Corrosion Resistance | Excellent (Will Not Tarnish) | Poor (Can Tarnish/Corrode) |

| Primary Value | Performance & Longevity | Precious Metal Content |

| Environmental Impact | Clean Process (No Hazardous Waste) | Chemical Baths (Require Disposal) |

Need a high-performance PVD coating for your laboratory equipment or components? KINTEK specializes in advanced lab equipment and consumables, providing durable surface solutions that enhance longevity and performance. Let our experts help you select the perfect coating for your application. Contact our team today to discuss your project requirements!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Touchscreen Automatic Vacuum Heat Press

- Lab Blown Film Extrusion Three Layer Co-Extrusion Film Blowing Machine

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

People Also Ask

- What is a sputtering system? Achieve Unmatched Thin Film Deposition for Your Lab

- What is magnetron sputtering machine? Precision Thin-Film Deposition for Advanced Materials

- What is the RF frequency for sputtering? Unlocking the Standard for Insulating Materials

- What is deposition in environmental chemistry? Understanding How Air Pollution Harms Ecosystems

- What are the effects of magnetron sputtering? Achieve High-Quality, Durable Thin Films for Your Lab