Grinding media is made from a specific range of hard, dense materials, most commonly ceramics, metals, glass, and natural minerals. The specific material is chosen based on the hardness of the product being milled, the required purity of the final product, and the intensity of the grinding process itself.

The selection of a grinding media material is not arbitrary. It is a critical decision that directly impacts processing efficiency, final product purity, and operational cost. The ideal choice balances hardness, wear resistance, and chemical inertness against the specific requirements of the task.

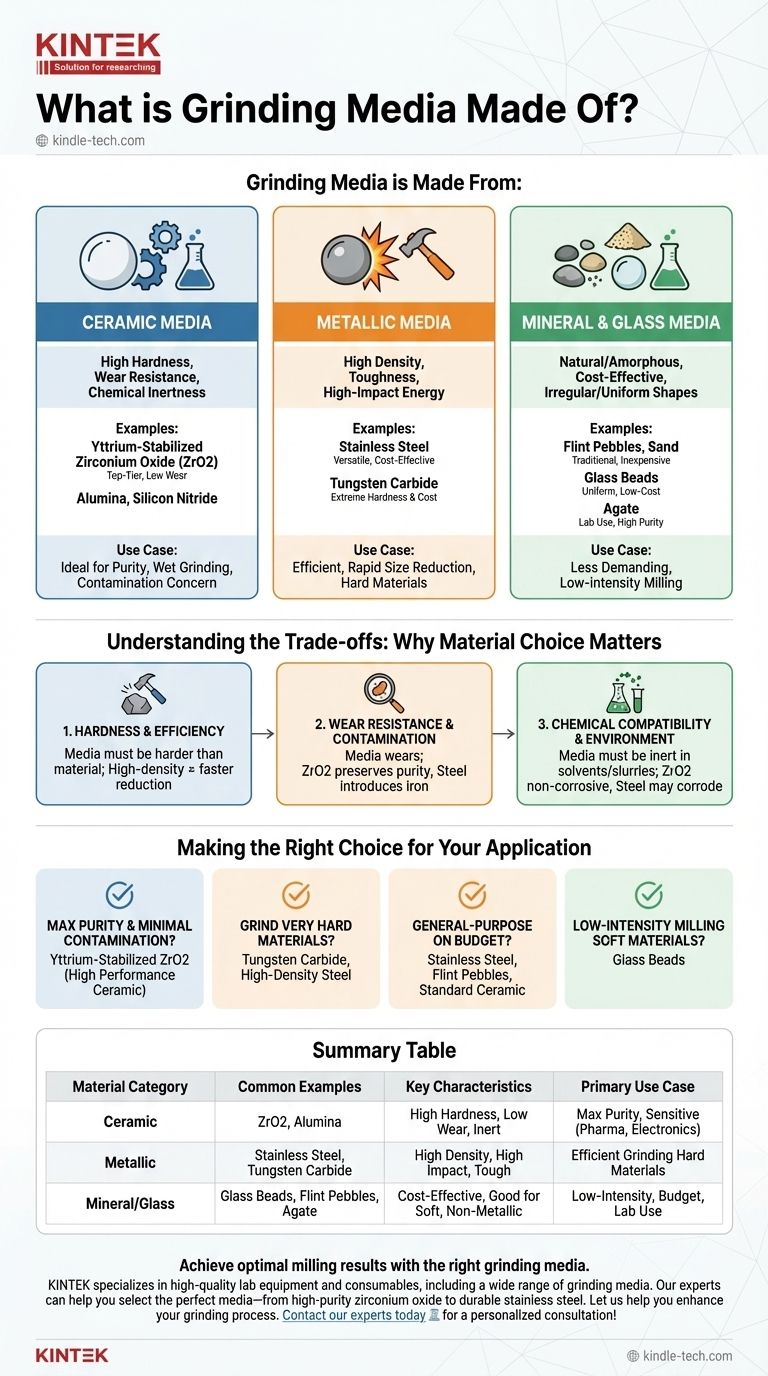

The Core Categories of Grinding Media Materials

Grinding media can be broadly classified into a few key material families. Each family offers a different profile of hardness, density, and cost, making them suitable for different applications.

Ceramic Media

Ceramics are prized for their high hardness, wear resistance, and chemical inertness, making them ideal for applications where contamination is a primary concern.

Materials like yttrium-stabilized zirconium oxide (ZrO2) are a top-tier choice. They are preferred for wet grinding due to exceptional hardness, toughness, and extremely low wear rates.

Other common ceramics include various formulations of alumina and silicon nitride, chosen for specific balances of cost and performance.

Metallic Media

Metals offer high density and toughness, resulting in high-impact energy for efficient and rapid size reduction.

Stainless steel is a widely used, versatile, and relatively cost-effective option for many ball milling applications where minor iron contamination is acceptable.

For grinding extremely hard materials, tungsten carbide is the superior choice. Its extreme hardness and density provide maximum grinding force, though at a significantly higher cost.

Less refined metal shots are also used in certain types of mills for more general-purpose applications.

Mineral and Glass Media

These natural or amorphous materials often provide a cost-effective solution for less demanding applications.

Flint pebbles and sand are traditional, inexpensive media. Their irregular shape and lower hardness make them suitable for certain low-intensity processes.

Glass beads provide a uniform, low-cost option for milling softer materials where avoiding metallic contamination is important but the extreme purity offered by high-end ceramics is not required.

Agate is a natural, microcrystalline quartz used in laboratory settings where its high purity and resistance to chipping are valued.

Understanding the Trade-offs: Why Material Choice Matters

Selecting the wrong media can lead to inefficient grinding, damaged equipment, or a contaminated final product. The decision hinges on three key factors.

Hardness and Grinding Efficiency

The fundamental rule is that the grinding media must be significantly harder than the material it is intended to grind.

High-density media like tungsten carbide or steel transfers more kinetic energy upon impact, leading to faster and more efficient particle size reduction.

Wear Resistance and Product Contamination

All grinding media wears down over time, introducing microscopic particles of itself into your product. This is a critical factor in industries like pharmaceuticals, electronics, and food.

Zirconium oxide (ZrO2) is valued for its exceptionally slow wear, preserving the purity of the milled substance. In contrast, using steel media will inevitably introduce iron contamination.

Chemical Compatibility and Environment

For wet grinding processes that involve solvents or acidic/alkaline slurries, the media must be chemically inert.

Materials like ZrO2 are described as "non-corrosive" and are ideal for these environments. Stainless steel may be suitable for some solvents but can corrode in others, compromising the entire batch.

Making the Right Choice for Your Application

Your choice of grinding media should be driven directly by your primary processing goal and budget.

- If your primary focus is maximum purity and minimal contamination: Use a high-performance ceramic like Yttrium-Stabilized Zirconium Oxide (ZrO2) due to its extreme wear resistance.

- If your primary focus is grinding very hard materials efficiently: Choose a high-density, ultra-hard medium like Tungsten Carbide or high-density steel balls.

- If your primary focus is general-purpose grinding on a budget: Stainless steel balls, flint pebbles, or standard-grade ceramic balls offer a reliable balance of performance and cost.

- If your primary focus is low-intensity milling of soft materials: Glass beads can be a perfectly suitable and cost-effective option that avoids metallic contamination.

Selecting the correct grinding media is the first step toward achieving a consistent, efficient, and high-quality milling process.

Summary Table:

| Material Category | Common Examples | Key Characteristics | Primary Use Case |

|---|---|---|---|

| Ceramic | Zirconium Oxide (ZrO2), Alumina | High hardness, excellent wear resistance, chemically inert | Maximum purity, minimal contamination (e.g., pharmaceuticals, electronics) |

| Metallic | Stainless Steel, Tungsten Carbide | High density, high-impact energy, tough | Efficient grinding of hard materials, general-purpose applications |

| Mineral/Glass | Glass Beads, Flint Pebbles, Agate | Cost-effective, good for softer materials, non-metallic | Low-intensity milling, budget-conscious applications, lab use |

Achieve optimal milling results with the right grinding media. The material you choose directly impacts your product's purity, processing efficiency, and operational costs. KINTEK specializes in high-quality lab equipment and consumables, including a wide range of grinding media. Our experts can help you select the perfect media—from high-purity zirconium oxide for sensitive applications to durable stainless steel for general use—ensuring your process is consistent and cost-effective.

Let us help you enhance your grinding process. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Hybrid Tissue Grinding Mill

- Laboratory Planetary Ball Mill Cabinet Planetary Ball Milling Machine

- High Energy Vibratory Laboratory Ball Mill Grinding Mill Single Tank Type

- High Performance Lab Homogenizer for Pharma Cosmetics and Food R&D

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the primary function of mechanical mixing equipment? Optimize C-SiC-B4C Composite Homogeneity

- How does the use of grinding equipment benefit iron-substituted manganese oxide? Optimize Energy Storage Performance

- What is the purpose of the grinding process for Titanium Dioxide? Maximize Surface Area and Photocatalytic Efficiency

- What is the mechanism of a grinding machine? Achieve Superior Precision and Surface Finishes

- How do you calculate ball mill capacity? Master the Bond Formula for Accurate Throughput

- What is an attritor mill? Achieve Rapid, Fine Grinding with High-Intensity Agitation

- What is the mechanism of action of a colloid mill? Master High-Shear Processing for Superior Emulsions and Dispersions

- What is the function of a three-roll mill in BSCF catalyst slurries? Achieve Perfect Nano-Scale Dispersion