In practice, "KBR technology" does not refer to a single invention. Instead, the term describes a vast portfolio of proprietary industrial processes and engineering solutions developed and licensed by KBR, Inc., a global leader in the energy, chemicals, and government services sectors. These technologies are foundational blueprints for producing essential commodities like ammonia for fertilizers, high-octane gasoline, and the chemical building blocks for plastics.

The core concept to grasp is that KBR is not just an engineering company that builds plants; it is a technology licensor. It designs and sells the highly efficient, protected "recipes" that other companies use to manufacture critical materials at an industrial scale.

The Company Behind the Technology

Understanding KBR's business model is key to understanding its technology. The company leverages decades of scientific research and operational data to create optimized industrial processes.

From Engineering Firm to Technology Powerhouse

KBR, Inc. has a long history, with roots in two predecessor companies: The M.W. Kellogg Company and Brown & Root. Both were major engineering and construction firms.

Over time, KBR evolved beyond just building infrastructure. It established itself as a premier developer of the underlying chemical and mechanical processes that make modern industry possible.

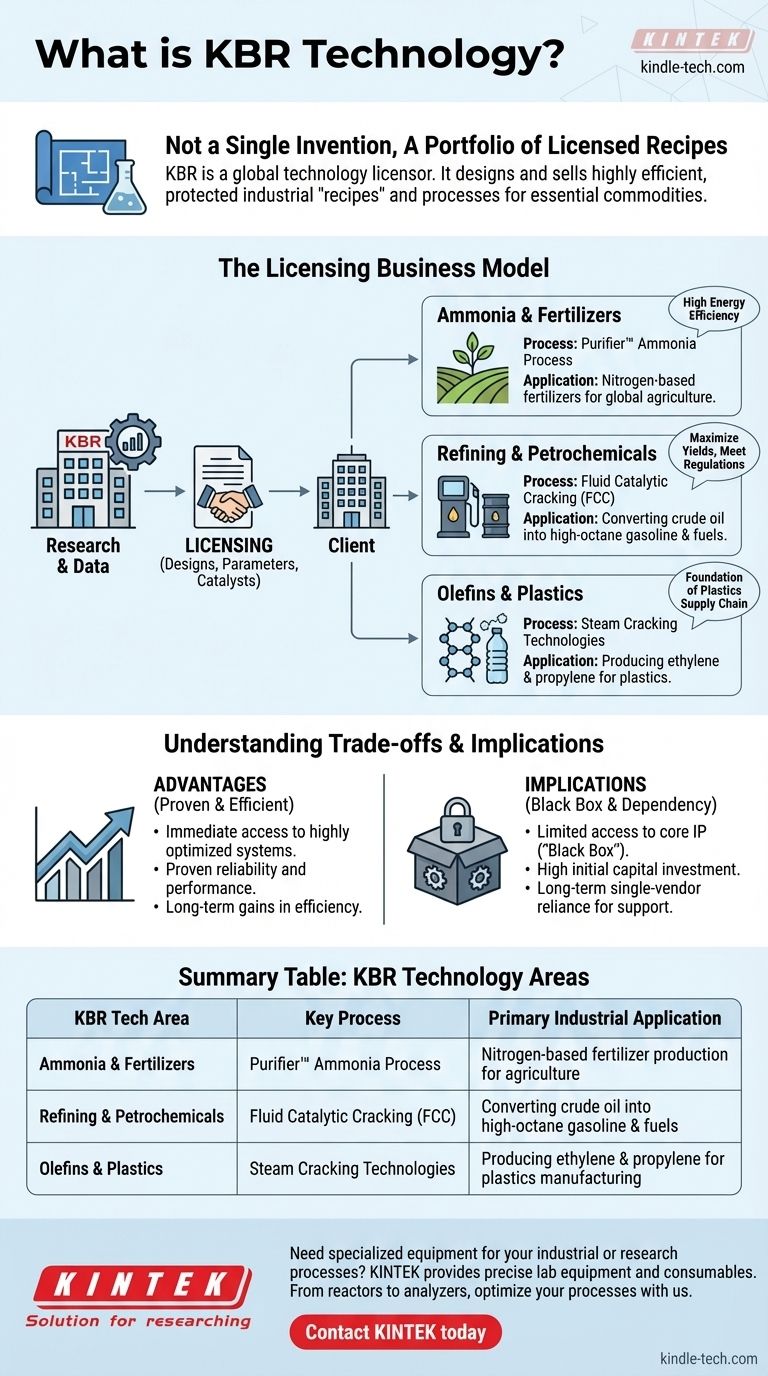

The Licensing Business Model

KBR’s primary technological impact comes from licensing. A company wanting to build a new ammonia plant or refinery unit doesn't have to invent the process from scratch.

Instead, they can license a proven, highly efficient process from KBR. This provides them with the engineering designs, operational parameters, and often the proprietary catalysts needed to run the plant effectively and profitably.

Core Areas of KBR Technological Expertise

KBR's portfolio is extensive, but its technologies have made the most significant impact in a few key areas that are fundamental to the global economy.

Ammonia and Fertilizers

KBR is a world leader in ammonia synthesis technology. Ammonia is the primary component of nitrogen-based fertilizers, which are essential for modern agriculture and feeding the world's population.

KBR processes, like their Purifier™ Ammonia Process, are known for their high energy efficiency and reliability, making them the design basis for a significant portion of the world's ammonia plants.

Refining and Petrochemicals

In oil refining, KBR provides critical technologies for converting crude oil into more valuable products. This includes Fluid Catalytic Cracking (FCC), a process that breaks down large hydrocarbon molecules into smaller ones that become components of gasoline.

Their refining solutions help producers maximize yields of high-demand products while meeting stringent environmental regulations.

Olefins and Plastics

Olefins, primarily ethylene and propylene, are the fundamental building blocks for the vast majority of plastics.

KBR's steam cracking technologies are used in massive industrial furnaces to produce these olefins from feedstocks like ethane or naphtha. The efficiency and flexibility of these designs are crucial for the profitability of the global plastics supply chain.

Understanding the Trade-offs and Implications

While licensing a proven technology from a leader like KBR offers immense advantages, it's important to understand the associated trade-offs.

The "Black Box" Nature of Licensing

When a company licenses a technology, it receives a blueprint for a highly optimized but often complex system. The licensee may not have access to the core intellectual property behind the catalysts or process models.

This creates a dependency on the licensor for ongoing support, troubleshooting, and future improvements.

High Initial Investment

Acquiring a license for a world-class technology represents a significant upfront capital investment. This cost is in addition to the immense expense of building the physical plant itself.

However, this investment is often justified by the long-term gains in efficiency, reliability, and product output compared to using a less advanced or unproven process.

Dependence on a Single Vendor

The process license, proprietary equipment, and specialized catalysts often come from a single source: KBR. This can create a long-term dependency for critical spare parts, catalyst refills, and technical support.

Making the Right Choice for Your Goal

Understanding KBR technology means recognizing its role as a specialized solution provider for large-scale industrial challenges.

- If your primary focus is agrochemicals or fertilizer production: KBR is a dominant force in designing high-efficiency, large-scale ammonia plants that are critical for the world's food supply.

- If your primary focus is oil refining: KBR provides essential technologies that allow refineries to convert crude oil into high-value fuels and meet environmental standards.

- If your primary focus is chemical manufacturing: KBR's expertise in olefins is fundamental to producing the ethylene and propylene that form the basis of the global plastics industry.

Ultimately, KBR technology represents a critical link between raw natural resources and the essential products that power our modern world.

Summary Table:

| KBR Technology Area | Key Process | Primary Industrial Application |

|---|---|---|

| Ammonia & Fertilizers | Purifier™ Ammonia Process | Nitrogen-based fertilizer production for agriculture |

| Refining & Petrochemicals | Fluid Catalytic Cracking (FCC) | Converting crude oil into high-octane gasoline and fuels |

| Olefins & Plastics | Steam Cracking Technologies | Producing ethylene and propylene for plastics manufacturing |

Need specialized equipment for your industrial or research processes? While KBR licenses large-scale chemical plant designs, KINTEK specializes in the precise lab equipment and consumables that support research, development, and quality control in these industries. From reactors to analyzers, our solutions help you optimize your processes. Contact KINTEK today to discuss your laboratory equipment needs.

Visual Guide

Related Products

- Laboratory Hybrid Tissue Grinding Mill

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- How full should a ball mill be? Achieve Peak Grinding Efficiency with the 50% Rule

- What are the different types of grinding mills? Match the Mechanism to Your Material for Optimal Size Reduction

- What is grinder in chemistry? A Guide to Precision Sample Preparation

- How many balls are needed for a ball mill? Optimize grinding with the right charge volume.

- Why grinding is important in laboratory techniques? Ensure Accurate & Reproducible Results