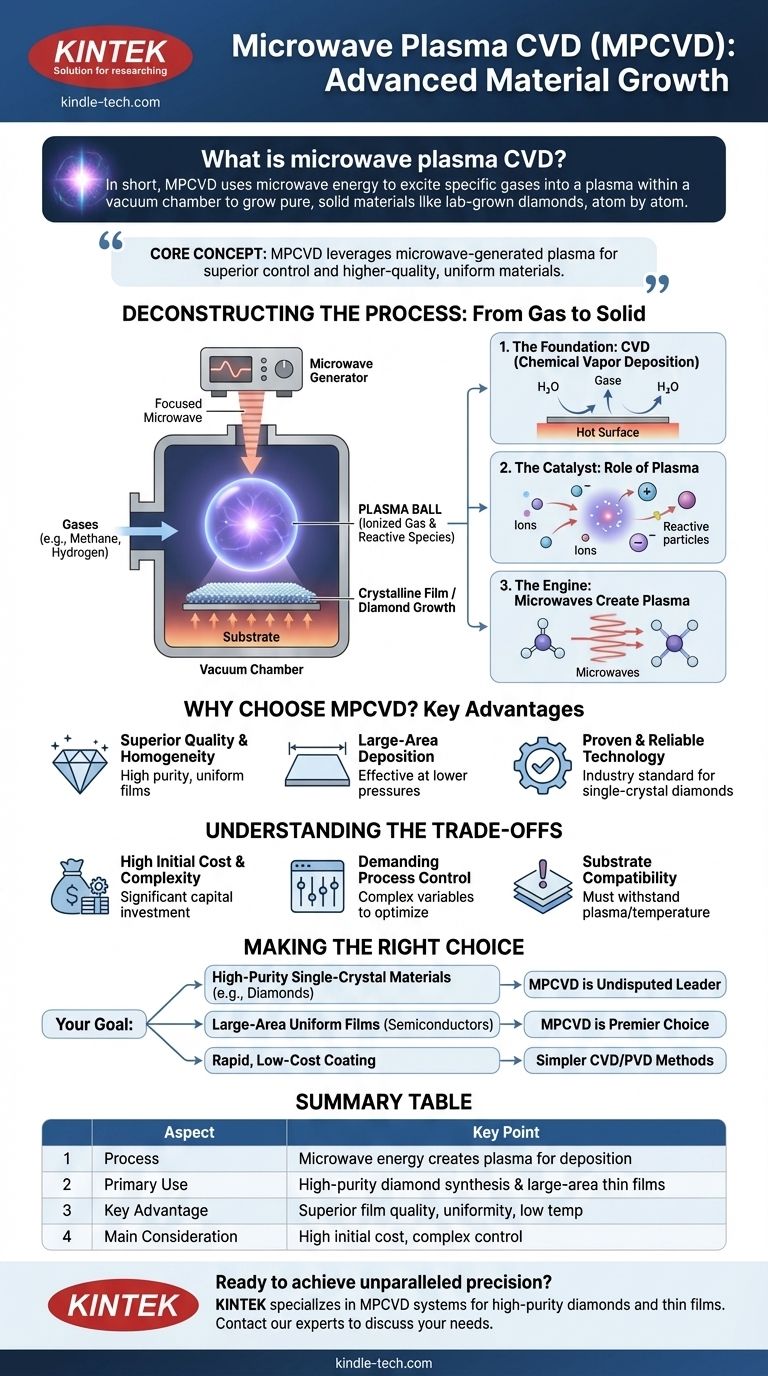

In short, Microwave Plasma Chemical Vapor Deposition (MPCVD) is a highly advanced process used to grow pure, solid materials, most notably lab-grown diamonds. It works by introducing specific gases, such as methane and hydrogen, into a vacuum chamber and then using microwave energy to excite those gases into a plasma. This plasma—a cloud of ionized gas—contains the reactive atomic ingredients needed to build a crystalline film, atom by atom, onto a substrate.

The core concept to grasp is that MPCVD leverages microwave-generated plasma as a highly efficient engine for material creation. This method provides superior control and produces higher-quality, more uniform materials over large areas compared to simpler deposition techniques.

Deconstructing the Process: From Gas to Solid

To fully understand MPCVD, it's helpful to break down its name into its three core components: Chemical Vapor Deposition (CVD), Plasma, and Microwaves. Each part plays a critical role in the final outcome.

The Foundation: Chemical Vapor Deposition (CVD)

CVD is a foundational technique for creating thin films and coatings. Think of it as a form of "atomic spray-painting."

The process involves introducing volatile precursor gases into a reaction chamber containing a heated surface, known as a substrate. A chemical reaction occurs on or near this hot surface, causing a solid material to deposit onto it.

By carefully controlling the gases, temperature, and pressure, CVD can produce everything from semiconductor layers in computer chips to wear-resistant coatings on machine tools.

The Catalyst: The Role of Plasma

While traditional CVD relies solely on heat to drive chemical reactions, plasma-enhanced methods add another layer of control and efficiency.

Plasma is often called the fourth state of matter. It's a gas that has been energized to the point where its atoms are broken apart into a soup of charged ions and highly reactive species.

Using plasma allows deposition to occur at lower temperatures and with greater precision. The reactive particles in the plasma are far more effective at building the desired material than the neutral gas molecules in thermal CVD.

The Engine: How Microwaves Create the Plasma

This is the key innovation of MPCVD. To create the plasma, the system directs focused microwave energy into the low-pressure gas inside the chamber.

This microwave energy is efficiently absorbed by the gas molecules (e.g., methane and hydrogen), energizing them into a stable, glowing plasma ball.

This plasma contains the dissociated carbon atoms and other species required for diamond growth. These reactive particles then settle onto the substrate, arranging themselves into the precise crystalline lattice of a diamond.

Why Choose MPCVD? The Key Advantages

MPCVD has become the most mature and widely adopted method for high-quality diamond synthesis for several clear reasons.

Superior Quality and Homogeneity

The high density of reactive particles in the microwave-generated plasma leads to the growth of exceptionally pure and uniform (homogeneous) films. This ensures consistent quality across the entire surface of the material.

Large-Area Deposition at Low Pressure

One of the significant industrial advantages of MPCVD is its ability to deposit high-quality films over large surface areas. It can also operate effectively at lower pressures, which enhances control over the film's properties.

Proven and Reliable Technology

For applications like growing large, single-crystal diamonds, MPCVD is the established industry standard. Its maturity provides a level of reliability and predictability that is crucial for commercial production.

Understanding the Trade-offs

No technology is without its limitations. To maintain an objective view, it's important to recognize the practical considerations of MPCVD.

High Initial Cost and Complexity

MPCVD systems are sophisticated pieces of equipment. They require precise vacuum chambers, high-power microwave generators, and complex gas handling systems, making the initial capital investment significant.

Demanding Process Control

While the process offers high control, it also involves numerous variables: gas composition, flow rates, pressure, microwave power, and substrate temperature. Optimizing a recipe for a specific outcome can be a complex engineering challenge.

Substrate Compatibility

The substrate material must be able to withstand the process conditions, including elevated temperatures and direct exposure to the highly reactive plasma. This can limit the types of materials that can be effectively coated.

Making the Right Choice for Your Goal

Selecting a deposition method depends entirely on the desired outcome, budget, and scale of your project.

- If your primary focus is producing high-purity, single-crystal materials like gem-quality diamonds: MPCVD is the undisputed industry leader, offering the necessary control and quality.

- If your primary focus is creating large-area, uniform semiconductor or optical films: MPCVD is a premier choice due to its excellent film homogeneity and scalability.

- If your primary focus is rapid, low-cost coating for general-purpose applications: The high investment and complexity of MPCVD may be excessive; simpler thermal CVD or physical vapor deposition (PVD) methods might be more appropriate.

Ultimately, MPCVD represents a pinnacle of material science, trading operational complexity for unparalleled precision and purity in the final product.

Summary Table:

| Aspect | Key Point |

|---|---|

| Process | Uses microwave energy to create a plasma from gases for material deposition. |

| Primary Use | High-purity lab-grown diamond synthesis and large-area thin films. |

| Key Advantage | Superior film quality, uniformity, and lower temperature operation. |

| Main Consideration | High initial cost and complex process control requirements. |

Ready to achieve unparalleled precision in your material synthesis? KINTEK specializes in advanced lab equipment, including MPCVD systems, to help you grow high-purity diamonds and uniform thin films with exceptional control. Our expertise supports researchers and industries in pushing the boundaries of material science. Contact our experts today to discuss how our solutions can meet your specific laboratory needs.

Visual Guide

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- CVD Diamond Domes for Industrial and Scientific Applications

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- What are the industrial uses of synthetic diamonds? Unlock High-Performance Solutions for Your Tech Needs

- What are the defects in CVD diamond? A Guide to Identifying and Assessing Quality

- How does microwave plasma work? Unlock Precision Material Synthesis for Advanced Manufacturing

- How do you make a lab diamond? Discover the HPHT and CVD Methods Explained

- Why do lab diamond prices vary so much? Understand the 4Cs and Market Forces

- Are artificial diamonds as strong as natural diamonds? Discover the Truth About Lab-Grown Diamond Durability

- What is a microwave plasma source? A Key Tool for Advanced Materials and Manufacturing

- What is the best color for a lab created diamond? Maximize Value with a Smarter Choice