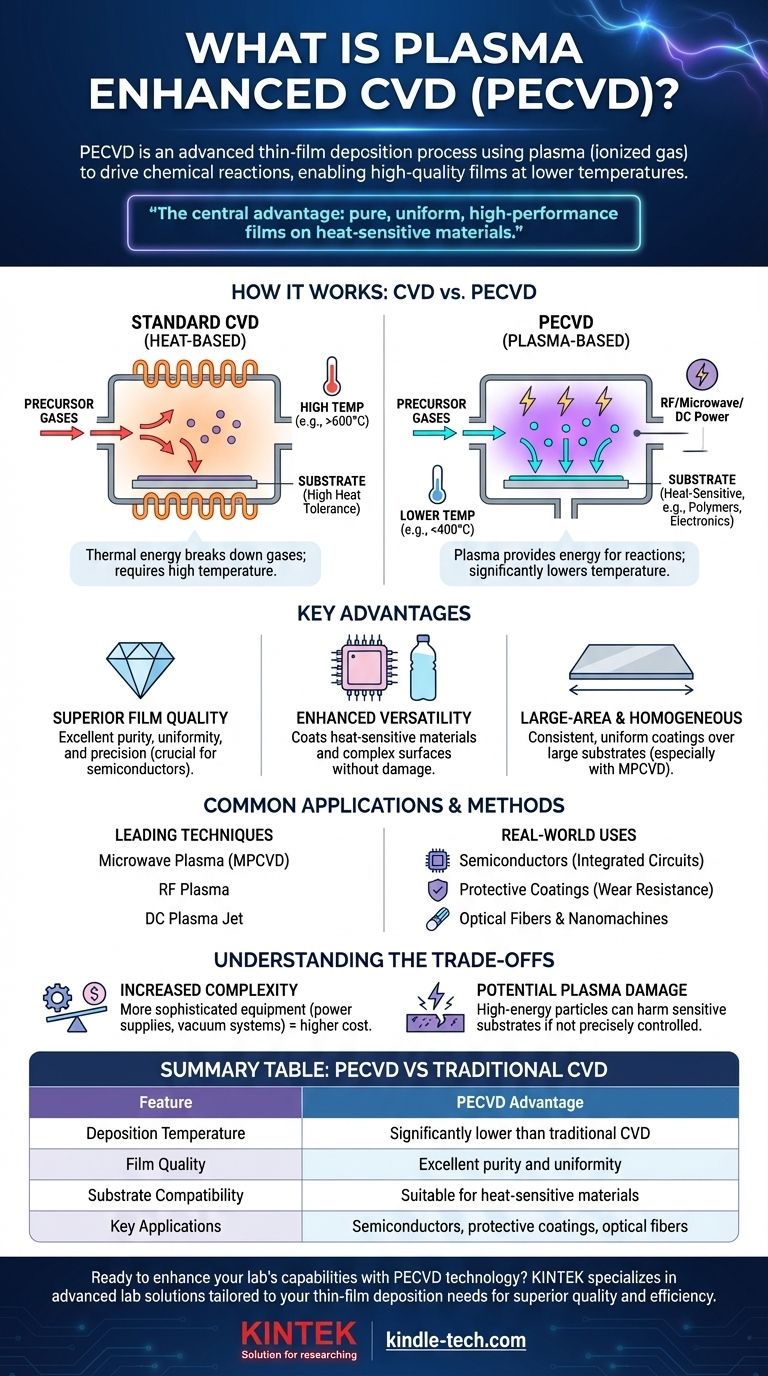

In short, Plasma Enhanced Chemical Vapor Deposition (PECVD) is an advanced process used to deposit high-quality thin films onto a substrate. It is a form of Chemical Vapor Deposition (CVD) that uses plasma—an ionized gas—to provide the energy for chemical reactions, rather than relying solely on high temperatures. This allows for deposition to occur at significantly lower temperatures, making it suitable for a wider range of materials.

The central advantage of PECVD is its ability to produce pure, uniform, and high-performance films at lower temperatures than traditional methods. This innovation unlocks the ability to coat heat-sensitive materials and achieve superior control over the final film properties.

How Standard CVD Sets the Stage

The Foundation: Chemical Reactions in a Gas

Traditional Chemical Vapor Deposition (CVD) works by introducing precursor gases into a reaction chamber. The chamber is heated to very high temperatures, providing the thermal energy needed to break down the gases.

Deposition onto a Substrate

The resulting chemical reactions cause a solid material to form and deposit as a thin, uniform film on the surface of a substrate. This method is highly effective for creating pure, durable coatings on both uniform and complex surfaces, overcoming the line-of-sight limitations of other techniques like Physical Vapor Deposition (PVD).

The Role of Plasma: The Core Innovation

Generating the Plasma

PECVD enhances this process by introducing energy in a different form. An electrical field (typically microwave, radio frequency (RF), or direct current (DC)) is applied to the gas, causing it to enter a plasma state.

Creating Reactive Species

This plasma is a highly energetic environment filled with a dense mix of ions, electrons, and other reactive particles. It serves as the catalyst for the chemical reactions.

Lowering the Temperature Barrier

Because the plasma provides the energy to break down the precursor gases, the process no longer depends on extreme heat. This dramatically lowers the required deposition temperature, which is the primary advantage of the PECVD method.

Key Advantages of Using PECVD

Superior Film Quality

The controlled, energetic environment of the plasma results in films with excellent purity and uniformity. This precision is critical in industries like semiconductor manufacturing, where flawless layers are essential.

Enhanced Versatility

The lower operating temperatures mean PECVD can be used to coat materials that would be damaged or destroyed by the heat of traditional CVD. This includes many polymers, plastics, and delicate electronic components.

Large-Area and Homogeneous Films

PECVD methods, particularly Microwave Plasma CVD (MPCVD), are well-suited for depositing highly consistent films over large areas. The process ensures better homogeneity compared to many other deposition techniques.

Common Applications and Methods

Leading PECVD Techniques

The most common methods are distinguished by how they generate the plasma: Microwave Plasma (MPCVD), RF Plasma, and DC Plasma Jet. Of these, MPCVD is a mature and widely used technique known for its ability to produce high-quality films like synthetic diamond.

Real-World Uses

PECVD is a foundational technology in many advanced industries. It is used to produce:

- Semiconductors for integrated circuits.

- Protective coatings, such as hard, diamond-like carbon films for wear resistance.

- High-performance materials for optical fibers, catalysts, and nanomachines.

Understanding the Trade-offs

Increased System Complexity

The primary trade-off with PECVD is equipment complexity. Generating and sustaining a stable plasma requires sophisticated power supplies, matching networks, and vacuum systems, making a PECVD setup more complex and costly than a simple thermal CVD reactor.

Potential for Plasma Damage

While the plasma is the key advantage, its high-energy particles can sometimes cause damage to the surface of a sensitive substrate if the process parameters are not carefully controlled. This requires precise engineering and process optimization to mitigate.

Making the Right Choice for Your Goal

PECVD is not a one-size-fits-all solution, but it is a powerful tool when applied correctly. Your end goal will determine if it's the right choice.

- If your primary focus is coating heat-sensitive substrates: PECVD is the definitive choice due to its low-temperature operation.

- If your primary focus is achieving maximum film purity and uniformity: PECVD offers exceptional control, making it ideal for high-performance applications like semiconductors.

- If your primary focus is coating large, non-uniform surfaces: The inherent advantages of CVD, enhanced by the plasma process, ensure consistent and homogeneous coatings.

Ultimately, PECVD empowers engineers and scientists to create advanced materials that would be impossible to fabricate using heat-based methods alone.

Summary Table:

| Feature | PECVD Advantage |

|---|---|

| Deposition Temperature | Significantly lower than traditional CVD |

| Film Quality | Excellent purity and uniformity |

| Substrate Compatibility | Suitable for heat-sensitive materials (e.g., polymers) |

| Key Applications | Semiconductors, protective coatings, optical fibers |

Ready to enhance your lab's capabilities with PECVD technology?

KINTEK specializes in advanced lab equipment and consumables, providing solutions tailored to your laboratory's thin-film deposition needs. Whether you're working with semiconductors, protective coatings, or delicate materials, our expertise ensures you achieve superior film quality and process efficiency.

Contact us today to discuss how our PECVD systems can drive your research and production forward!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- What is plasma activated Vapour deposition? A Low-Temperature Coating Solution

- What materials are used in PECVD? Unlock Low-Temperature Deposition for Sensitive Substrates

- Is DLC coating corrosion resistant? Maximizing Protection with the Right Surface Engineering

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- What is the temperature of SiO2 PECVD? Achieve Low-Temp, High-Quality Films for Sensitive Substrates

- What are the common applications of PECVD systems in the semiconductor industry? Enhance Your Thin-Film Fabrication

- What is the function of a Microwave PECVD system for Diamond Nanospikes? Precision 1-Step Nanostructure Synthesis

- What are the advantages of plasma enhanced chemical vapor deposition? Enable Low-Temperature, High-Quality Film Deposition