Plasma pyrolysis is an advanced thermal waste treatment process that uses the intense energy of plasma to break down waste materials at extremely high temperatures. Unlike standard pyrolysis, which heats waste in the absence of oxygen, plasma pyrolysis utilizes an electrically charged gas (plasma) to achieve temperatures often exceeding 3,000°C, dissociating complex materials like plastics, hazardous waste, or medical waste into their fundamental elemental components.

At its core, plasma pyrolysis is not just about breaking down waste; it's about complete molecular dissociation. This process excels at destroying the most challenging waste streams, producing a clean, simple syngas and an inert, non-leachable solid, but at a significantly higher energy cost and complexity than traditional methods.

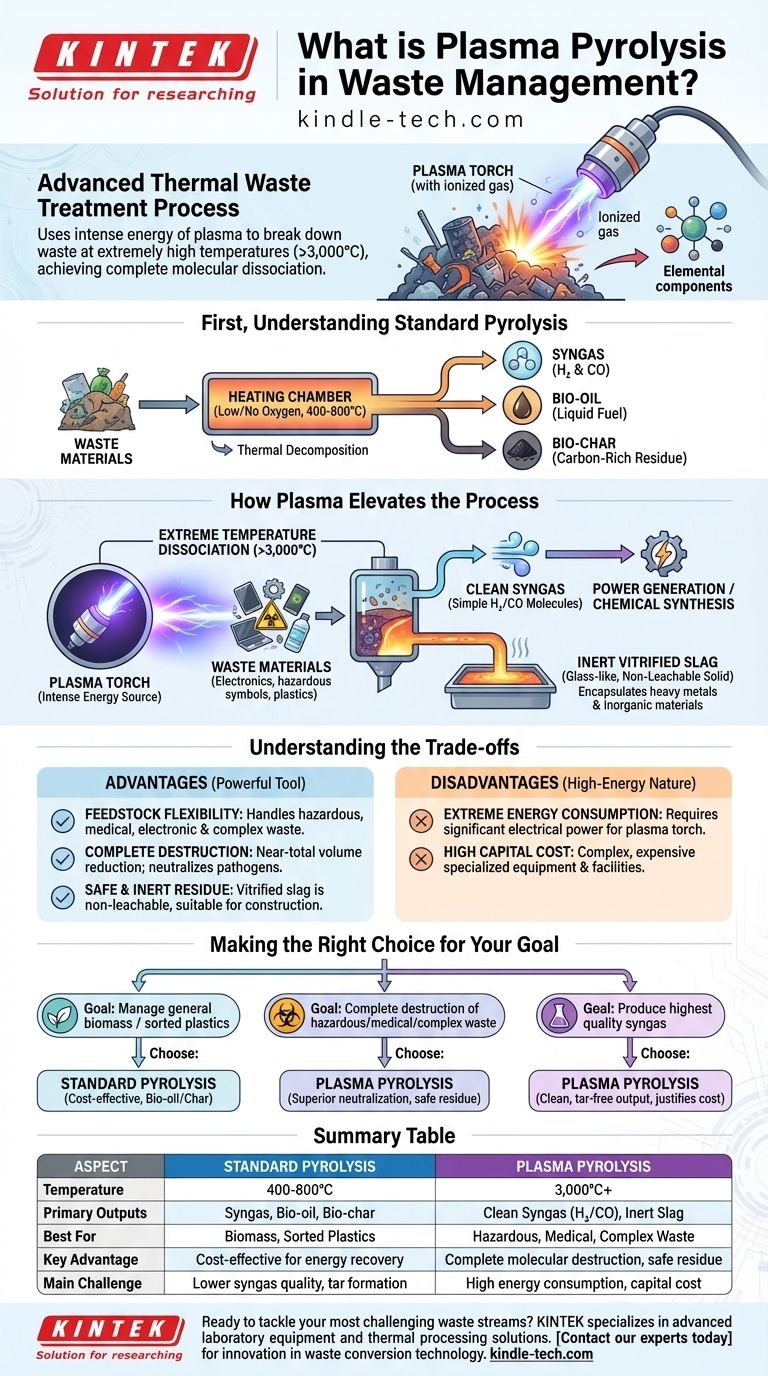

First, Understanding Standard Pyrolysis

To appreciate what makes plasma pyrolysis unique, we must first understand the foundation it builds upon: standard pyrolysis.

The Basic Mechanism

Standard pyrolysis is the process of heating waste materials in an environment with little to no oxygen. This prevents combustion (burning) and instead causes the materials to thermally decompose.

The End Products

This decomposition breaks down complex organic materials into three primary products:

- Syngas: A mixture of combustible gases, primarily hydrogen and carbon monoxide.

- Bio-oil (or Pyrolysis Oil): A liquid fuel that requires further refining.

- Bio-char: A solid, carbon-rich residue similar to charcoal.

These products have value and can be used as fuel, soil amendments, or as feedstock for producing other chemicals.

How Plasma Elevates the Process

Plasma pyrolysis takes this basic concept to an extreme, using a plasma torch to create conditions far more intense than conventional heating methods can achieve.

The Role of the Plasma Torch

A plasma torch passes a gas (like air or argon) through an electric arc. This superheats the gas, stripping electrons from the atoms and creating an ionized, electrically conductive gas stream—the plasma.

Extreme Temperature Dissociation

This plasma torch acts as a source of intense, concentrated thermal energy, raising the temperature inside the reactor to several thousand degrees Celsius. At these temperatures, waste doesn't just decompose; its molecules are torn apart into their constituent atoms.

The Superior Output: Syngas and Slag

Because of this complete molecular dissociation, the outputs are fundamentally different from standard pyrolysis. Tars and complex oils are virtually eliminated.

The process primarily yields two things:

- A high-quality syngas composed almost entirely of simple hydrogen (H₂) and carbon monoxide (CO) molecules.

- An inert, vitrified slag, which is a glass-like, non-leachable solid material that safely encapsulates inorganic materials and heavy metals.

Understanding the Trade-offs

Choosing plasma pyrolysis involves a clear set of trade-offs defined by its high-energy nature. It is a powerful tool, but not a universal solution for all waste problems.

Advantage: Feedstock Flexibility

Plasma systems can handle nearly any type of waste, including hazardous materials, medical waste, electronics, and mixed municipal solid waste that would be problematic for other technologies. The extreme heat neutralizes pathogens and breaks down complex chemical bonds.

Advantage: Complete Destruction

The process results in near-total waste destruction and volume reduction. The final slag is typically inert and safe for use as construction aggregate, eliminating future landfill liability. The syngas produced is also cleaner and more versatile than that from standard pyrolysis.

Disadvantage: Extreme Energy Consumption

The primary drawback is the significant electrical energy required to power the plasma torch. This makes the operational cost very high and means the process may only be energy-positive if the produced syngas is used very efficiently to generate electricity.

Disadvantage: High Capital Cost

Plasma gasification plants are more complex and expensive to build than standard pyrolysis or incineration facilities. The specialized equipment, including the plasma torches and high-temperature reactor, represents a major capital investment.

Making the Right Choice for Your Goal

The decision to use plasma pyrolysis must be driven by the specific nature of the waste stream and the desired outcome.

- If your primary focus is managing general biomass or sorted plastics: Standard pyrolysis is often a more cost-effective and energy-efficient solution for producing bio-oil and char.

- If your primary focus is the complete and safe destruction of hazardous, medical, or complex industrial waste: Plasma pyrolysis is a superior technology for achieving neutralization and producing a stable, non-toxic solid residue.

- If your primary focus is producing the highest quality syngas for chemical synthesis or efficient power generation: The clean, tar-free output of plasma pyrolysis can justify its higher cost by simplifying downstream gas cleanup processes.

Ultimately, plasma pyrolysis represents the cutting edge of thermal waste conversion, offering unparalleled destruction capability for the most difficult waste streams.

Summary Table:

| Aspect | Standard Pyrolysis | Plasma Pyrolysis |

|---|---|---|

| Temperature | 400-800°C | 3,000°C+ |

| Primary Outputs | Syngas, Bio-oil, Bio-char | Clean Syngas (H₂/CO), Inert Slag |

| Best For | Biomass, Sorted Plastics | Hazardous, Medical, Complex Waste |

| Key Advantage | Cost-effective for energy recovery | Complete molecular destruction, safe residue |

| Main Challenge | Lower syngas quality, tar formation | High energy consumption, capital cost |

Ready to tackle your most challenging waste streams? KINTEK specializes in advanced laboratory equipment and thermal processing solutions. Our expertise can help you evaluate if plasma pyrolysis is the right technology for your hazardous waste management goals. Contact our experts today to discuss how we can support your lab's innovation and efficiency in waste conversion technology.

Visual Guide

Related Products

- 20L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 50L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Multifunctional Electrolytic Electrochemical Cell Water Bath Single Layer Double Layer

People Also Ask

- How does a thermostatic water bath function in ODS steel corrosion tests? Ensure Precise Bio-Simulation Accuracy

- How do circulating cooling systems ensure accuracy in adsorption tests? Stabilize Thermal Variables for Precise Data

- How does a high-precision constant temperature circulator contribute to mineral dissolution kinetic studies?

- For which types of substances are water baths and chillers considered ideal? Essential Care for Sensitive Samples

- What is the primary function of water baths and chillers? Mastering Precise Thermal Stability for Liquid Samples