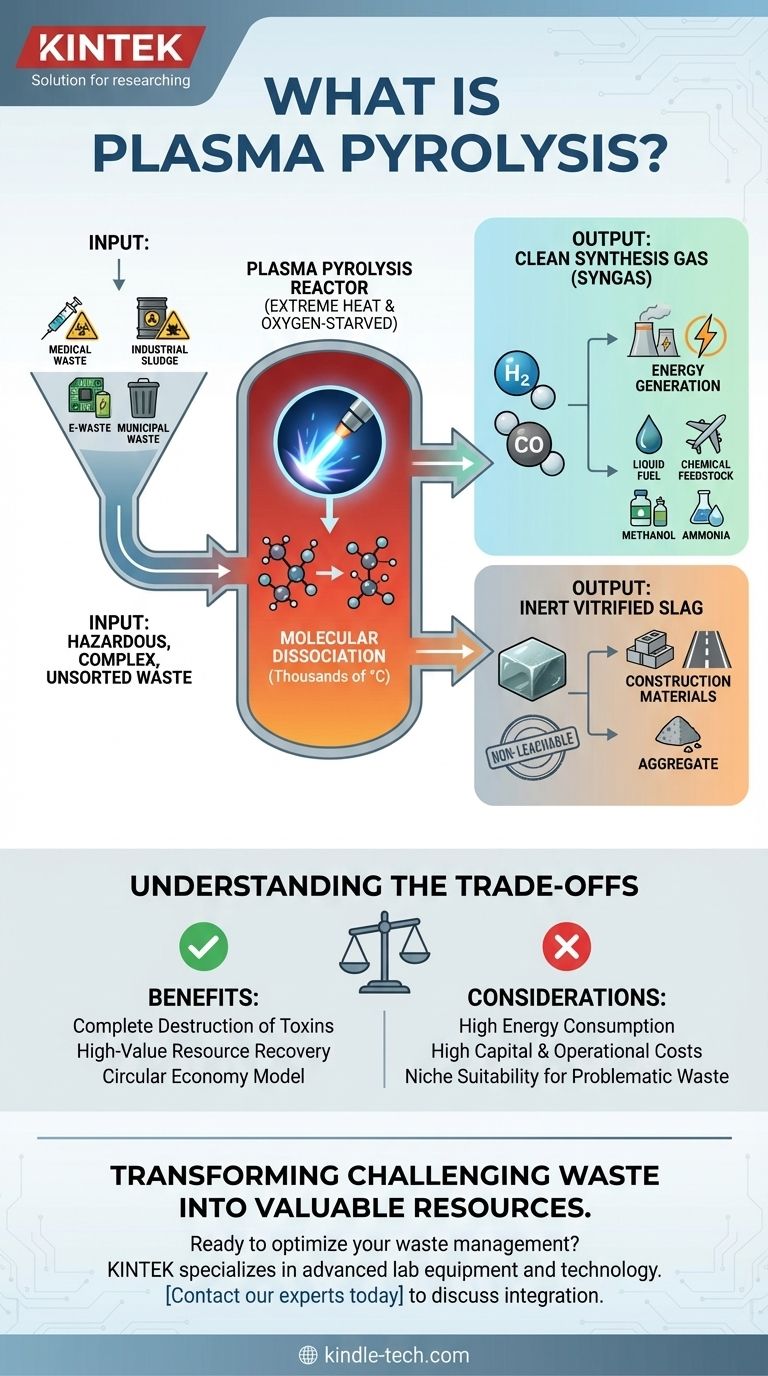

At its core, plasma pyrolysis is an advanced thermal treatment process used to safely and completely break down hazardous, complex, or unsorted waste materials. Unlike conventional methods, it uses the extreme heat of an electrical plasma torch to decompose waste in an oxygen-starved environment, converting it into a valuable synthesis gas (syngas) and an inert, non-toxic solid.

The crucial distinction is that plasma pyrolysis isn't merely for waste disposal; it's a high-value conversion technology. It excels at transforming problematic waste streams that are difficult to manage—like medical or industrial waste—into clean energy and safe, reusable materials.

The Core Function: High-Temperature Waste Conversion

Plasma pyrolysis leverages ionized gas, or plasma, to achieve temperatures far exceeding those of conventional pyrolysis or incineration, often reaching several thousand degrees Celsius. This intense, localized heat provides unique capabilities.

Breaking Down Any Carbon-Based Material

The process works by molecular dissociation. The plasma's energy is so high that it breaks the chemical bonds of the feedstock, reducing complex compounds into their simplest elemental components.

Handling Difficult and Hazardous Waste

This technology is specifically suited for waste streams that are otherwise dangerous or costly to handle. Key examples include medical waste, industrial sludges, electronic waste (e-waste), and unsorted municipal solid waste.

Producing High-Quality Syngas

A primary output is a clean synthesis gas, or syngas. This gas is rich in hydrogen and carbon monoxide, which are fundamental chemical building blocks and can be used as a clean fuel. The high temperature ensures the complete destruction of hazardous compounds like dioxins and furans.

Creating an Inert, Vitrified Solid

Instead of ash or biochar, the inorganic materials in the waste (like metals, glass, and silica) are melted down into a stable, glass-like solid called slag. This slag is non-leachable, meaning hazardous materials are permanently locked within its structure, rendering them safe.

Key Applications of the Outputs

The value of plasma pyrolysis lies not just in destroying waste but in creating useful products from it. This aligns with a waste-to-value or circular economy model.

Syngas for Energy Generation

The most common application for the produced syngas is direct combustion in gas engines or turbines to generate electricity. This creates a source of renewable energy from a waste feedstock, reducing reliance on fossil fuels.

Feedstock for Liquid Fuels and Chemicals

The clean syngas can also serve as a chemical feedstock. Through processes like Fischer-Tropsch synthesis, it can be converted into high-value liquid fuels like diesel and jet fuel, or other chemicals like methanol and ammonia.

Vitrified Slag for Construction

The inert slag byproduct is safe and durable. It can be used as a high-quality aggregate in materials like concrete, asphalt, or decorative tiles, effectively closing the waste loop.

Understanding the Trade-offs

While powerful, plasma pyrolysis is a specialized technology with specific considerations. It is not a universal solution for all waste types.

High Energy Consumption

Creating and sustaining the plasma arc is an energy-intensive process. A significant portion of the energy generated from the syngas may be required to power the system itself, impacting the net energy output.

High Capital and Operational Costs

Plasma pyrolysis facilities are technologically complex and expensive to build and operate compared to more traditional waste management methods like landfilling or conventional incineration.

Niche Suitability

Due to its cost and complexity, this technology is best reserved for high-value applications. It is most economically viable for treating hazardous or highly problematic waste streams where the cost of alternative disposal methods is already very high.

Making the Right Choice for Your Goal

Selecting a thermal technology depends entirely on your feedstock and your primary objective.

- If your primary focus is the safe disposal of hazardous or complex waste: Plasma pyrolysis is a superior choice for its ability to completely destroy toxins and produce inert, safe byproducts.

- If your primary focus is maximizing energy recovery from diverse waste: This technology is highly effective at converting nearly any carbon-based material into a clean, energy-rich syngas.

- If your primary focus is processing uniform organic material (e.g., agricultural biomass): Simpler, less expensive methods like conventional fast pyrolysis are often more cost-effective for producing bio-oil and biochar from these feedstocks.

Ultimately, plasma pyrolysis represents a powerful tool for converting society's most challenging wastes into valuable resources.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Function | High-temperature decomposition of waste in an oxygen-starved environment. |

| Key Inputs | Hazardous, complex, or unsorted waste (e.g., medical, industrial, e-waste). |

| Primary Outputs | Clean syngas (for energy/fuel) and inert, vitrified slag (for construction). |

| Best For | Safe disposal of problematic waste and high-value resource recovery. |

| Considerations | High energy consumption and significant capital/operational costs. |

Ready to transform your challenging waste streams into valuable resources?

Plasma pyrolysis is a powerful, specialized solution for laboratories and industrial facilities dealing with hazardous or complex waste. KINTEK specializes in advanced lab equipment and consumables, providing the technology and expertise to help you safely convert waste into clean energy and reusable materials.

Contact our experts today to discuss how plasma pyrolysis can be integrated into your operations and contribute to your sustainability goals.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- Why is it important to autoclave the prepared reagents before using? Ensure Sterility and Reliable Results

- What are the sizes of autoclaves? A Guide to Choosing the Right Capacity for Your Lab

- What is a lab autoclave? Your Guide to Sterilization with Pressurized Steam

- How do you sterilize glassware by autoclave? Master the 3-Step Process for Reliable Sterility

- What is the use of autoclave in medical? The Critical Role of Sterilization in Patient Safety