In the world of dental prosthetics, a porcelain furnace is a specialized, high-temperature oven designed for the precise processing of dental porcelain powders. It is the critical equipment used to fire, sinter, and glaze raw ceramic materials, transforming them into strong, aesthetically pleasing, and durable dental restorations like crowns, bridges, and veneers.

A porcelain furnace is not merely an oven; it is a precision instrument engineered to control heat and atmosphere with extreme accuracy. Its primary purpose is to mature raw dental ceramics while meticulously preserving the essential aesthetic qualities—like color, translucency, and texture—that define a high-quality restoration.

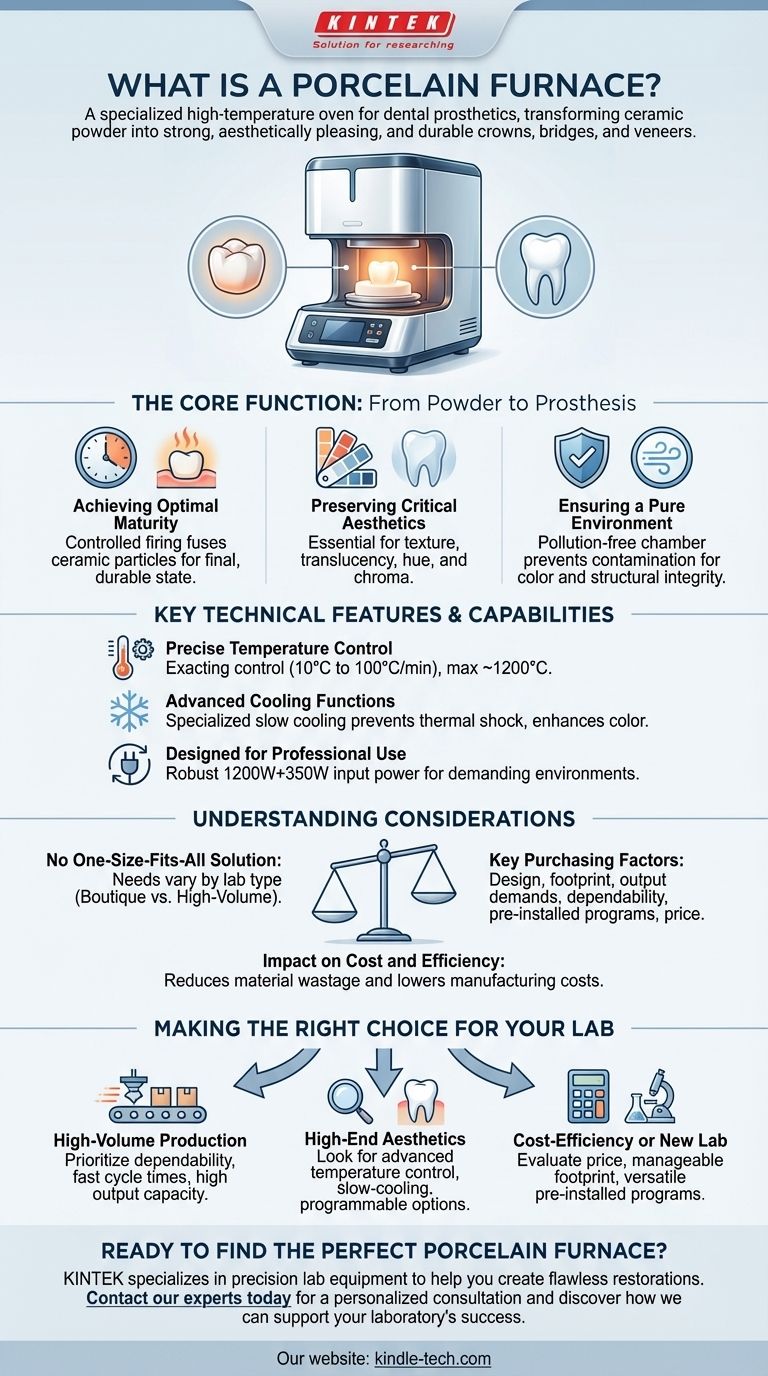

The Core Function: From Powder to Prosthesis

A porcelain furnace is central to the dental laboratory's workflow, acting as the final step in creating lifelike restorations from formless powder. Its performance directly dictates the quality of the final product.

Achieving Optimal Maturity

The furnace heats the raw, sculpted porcelain according to a precise schedule. This controlled heating process, known as firing or sintering, fuses the ceramic particles together, hardening the material to its final, durable state.

Preserving Critical Aesthetics

The ultimate goal of a dental restoration is to be indistinguishable from a natural tooth. A high-quality furnace is essential for maintaining key aesthetic features, including surface texture, translucency, value, hue, and chroma.

Ensuring a Pure Environment

The internal working chamber of a dental porcelain furnace is designed to be pure and pollution-free. This prevents any contaminants from embedding in the porcelain during the high-temperature firing process, which could otherwise compromise the restoration's color and structural integrity.

Key Technical Features and Capabilities

Modern porcelain furnaces are high-performance devices equipped with advanced features that enable dental technicians to achieve consistent, high-quality results.

Precise Temperature Control

These furnaces offer exacting control over heating rates, often ranging from 10°C to 100°C per minute, with a maximum working temperature around 1200°C. This precision allows technicians to use a wide variety of dental porcelain materials, each with its own specific firing requirements.

Advanced Cooling Functions

Many furnaces include specialized cooling capabilities. A tempering or slow cooling function is particularly important, as it helps prevent thermal shock, enhances color effects, and improves the overall quality and stability of the porcelain.

Designed for Professional Use

Technical specifications, such as an input power of 1200W+350W, reflect their role as robust equipment for professional denture processing plants. They are built for reliability and consistent output in a demanding environment.

Understanding the Trade-offs and Considerations

When investing in a new porcelain furnace, it is crucial to recognize that there is no single best option for every laboratory. The right choice depends on a careful evaluation of specific needs and operational goals.

No One-Size-Fits-All Solution

The ideal furnace for a small boutique lab focused on aesthetics will differ from one needed by a high-volume production facility. It is essential to begin the purchasing process by assessing your lab's unique requirements.

Key Purchasing Factors

Several factors must be weighed, including the furnace's design style, its footprint and space requirements in the lab, and its capacity to meet output demands. Other critical considerations are dependability, the availability of pre-installed programs for various materials, and the overall price.

The Impact on Cost and Efficiency

A well-chosen, high-performance furnace is an investment that pays dividends. By ensuring predictable results and minimizing errors, a "perfect furnace" reduces the wastage of material and lowers the overall cost of manufacturing restorations.

Making the Right Choice for Your Lab

Selecting the right furnace requires aligning the equipment's capabilities with your laboratory's primary business objectives.

- If your primary focus is high-volume production: Prioritize furnaces known for their dependability, fast cycle times, and capacity to meet high output demands.

- If your primary focus is high-end aesthetic restorations: Look for furnaces with advanced temperature control, specialized slow-cooling functions, and extensive programmable options to handle complex ceramic materials.

- If your primary focus is cost-efficiency or a new lab setup: Evaluate furnaces that offer the best balance of price, a manageable footprint, and versatile pre-installed programs to handle a variety of common cases.

Ultimately, the porcelain furnace is the cornerstone of quality in a dental laboratory, directly translating a technician's skill into a flawless final product.

Summary Table:

| Feature | Benefit for Your Lab |

|---|---|

| Precise Temperature Control | Ensures optimal maturity for various ceramic materials. |

| Advanced Cooling Functions | Prevents thermal shock and enhances color stability. |

| Pure Firing Environment | Guarantees consistent color and structural integrity. |

| Pre-Installed Programs | Saves time and reduces errors for common materials. |

Ready to find the perfect porcelain furnace for your lab's unique needs?

Whether your focus is high-volume production, superior aesthetics, or cost-effective startup, the right furnace is a cornerstone of quality and efficiency. KINTEK specializes in precision lab equipment, including dental porcelain furnaces, to help you create flawless restorations while reducing material waste.

Contact our experts today for a personalized consultation and discover how we can support your laboratory's success.

Visual Guide

Related Products

- Vacuum Dental Porcelain Sintering Furnace

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Can high fusing porcelain be repaired without distortion? Yes, with the right low-fusing materials and techniques.

- What is a porcelain furnace in dentistry? The Key to Creating Strong, Aesthetic Dental Restorations

- What is the firing temperature of dental porcelain? A Guide to Classes from Ultra-Low to High-Fusing

- What does sintering do to zirconia? Unlock Its Full Strength and Aesthetic Potential

- What makes zirconia translucent? The Science Behind Modern Dental Aesthetics

- Why is zirconia sintered? To Unlock Its Full Strength and Aesthetic Potential

- What does sintering zirconia mean? The Key to Transforming Zirconia into a High-Strength Ceramic

- What temperature is a dental sintering furnace? Mastering the Material-Specific Thermal Cycle